Echo Sounder and Speed Log

Echo Sounder

Basic Principle

Short pulses of sound vibrations are transmitted from

the bottom of the ship to the seabed. These sound waves are reflected back by

the seabed and the time taken from transmission to reception of the reflected

sound waves is measured. Since the speed

of sound in water is 1500 m/sec, the depth of the sea bed is calculated which

will be half the distance travelled by the sound

waves.

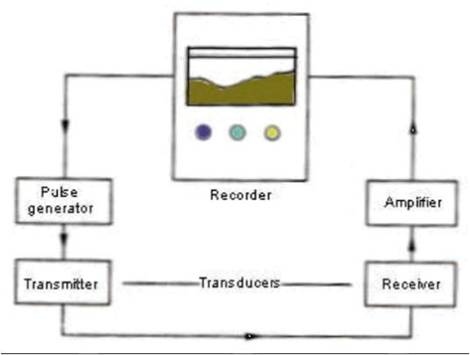

COMPONENTS

Basically an echo sounder has following components:

Transducer to generate the

sound vibrations and also receive the reflected sound vibration.

Pulse generator to produce electrical oscillations

for the transmitting transducer.

Amplifier to amplify the weak electrical

oscillations that has been generated by the receiving transducer on reception

of the reflected sound vibration.

Recorder - for measuring and indicating

depth.

CONTROLS

An echo sounder will normally have the following

controls:

Range Switch to select the range between which the

depth is be checked e.g. 0- 50 m, 1 100 m, 100 200 m etc. Always

check the lowest range first before shifting to a higher range.

Unit selector switch to select the unit feet,

fathoms or meter as required.

Gain switch to be adjusted such that the clearest

echo line is recorded on the paper.

Paper speed control to select the speed of the paper

usually two speeds available.

Zero Adjustment or Draught setting control the echo

sounder will normally display the depth below the keel. This switch can be used to feed the ships

draught such that the echo sounder will display the total sea depth. This switch is also used to adjust the start

of the transmission of the sound pulse to be in line with the zero of the scale

in use.

Fix or event marker - this button is used to draw a line

on the paper as a mark to indicate certain time e.g. passing a navigational

mark, when a position is plotted on the chart etc.

Transducer changeover switch in case vessel has more

than one switch e.g. forward and aft transducer.

Dimmer to illuminate the display as required.

More on the principle of Echo Sounding

Echo sounder equipment makes use of sound (or sonic)

waves, which differ from radio waves in several ways. Sound waves vibrate in

the direction of travel of the wave front Sound wave velocity is comparatively

low (in comparison with radio waves). Sound waves can travel through a material

medium such as a gas, a liquid or a solid, but not a vacuum.

Sound waves can be produced over a very wide range of

frequencies, and these waves exert definite pressure variations, which under

certain circumstances can be measured. The audible frequency or frequencies

that human beings can detect varies, but an approximate range of detection

(also called as the normal range) can be considered as lying between about 20

Hz to 20,000 Hz. Those above the normal range of the human ear are termed

ultrasonic or supersonic frequencies.

There is a loss of energy when any waves are

transmitted through a medium and the losses increase as the frequencies

increase. Sound waves also suffer losses, however in

water such losses are of the order of 1000 times less as compared to the loss

in air. Supersonic vibrations are therefore much more suitable for transmission

in water than in air. The losses do increase due to high frequency,

however they do not become serious unless very high frequencies are used.

Water is an excellent sound transmitting medium as the

velocity of sound in the water is known accurately and it does not vary more

than about 3%, if temperature and salinity change.

The speed of sound increases as water temperature,

salinity and water pressure increases, and all of the above vary with depth.

The speed of sound varies from about 1432 metres/sec. in fresh water, to about

1535 metres/sec. in salt water of high salinity. For depth sounding equipment

design purpose a sound speed value of 1500 metres/sec. are assumed.

For normal applications on merchant vessels, the

indication of the depth value based on the average speed of sound (1500 m/sec.)

causes a minor error when changing from Salt Water (SW) to Fresh Water (FW).

Assuming there is a small correction adjustment for SW, the true depth in FW is

found to be about 3% less than the indicated depth. As can be seen, this

deviation is very small and thus insignificant for practical considerations.

When sound wave passes through an interface of two

mediums, besides suffering loss of energy, they refract as well as reflect

(critical refraction) at the boundary where the two media meet.

The Practice of Echo Sounding

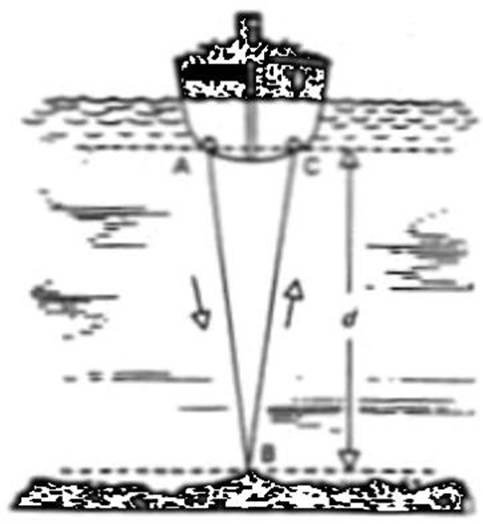

The echo sounding principles is used as follows, to

measure depth. A short sound pulse is transmitted from the ship's bottom

towards the seabed where it is reflected back towards the hull as an echo.

The time interval between transmission of the pulse

and the receipt of the echo is measured, and the depth is found from the

expression:

Depth = velocity X time divided by 2

The frequency of the sound vibrations created in the

water during pulsing is usually at the upper end of, or above the audible

range. A depth sounder instrument can be obtained in three different forms

based on the transmitted frequency:

.1 using

14khz frequency (Low end sounders)

.2 using

14 kHz to 30 kHz frequency (Normal sounders)

.3 using

30 kHz frequency (High end sounders)

The choosing of frequency depends on the requirements

of the user. The chosen frequency is basically a compromise to avoid

interference from audible ship motion noise, and water losses through the

seawater.

Generally low frequencies are mostly affected by ship

noise and high frequencies by water losses, which are caused by absorption.

The sound pulses are created by transducers, which

convert electrical energy on transmission, and reverse the process when the

echo is received. The sound energy is always transmitted as a beam in a

particular direction (directional beam) and it would be very wasteful to permit

spherical radiation.

Transducers

are of two types:

Piezo-electric

transducer

Magneto-striction transducer.

Piezo-electric

transducer

This type makes use of the special properties of

crystals (e.g. crystals of barium-titanate and lead zirconate). If an alternating voltage is applied to the

opposite faces of a flat piece of one of the above materials, the crystal will

expand and contract, and hence vibrate creating sound waves for as long as the

vibrations continue. The process is reversible, i.e. when varying pressure from

a returning echo, is applied to the opposite faces, an

alternating voltage is generated across the faces and the same can be further

amplified and used to activate an indicator.

Magneto-striction transducer

In this type, the use is made of the magneto-striction effect which is a phenomenon whereby

magnetization of ferromagnetic materials produce a small change in their dimensions,

and conversely the application of mechanical stresses such as weak pressure

vibrations, as from an echo to them, produce magnetic changes in them; e.g. a

nickel bar when placed in the direction of or strength of the magnetic field.

If the nickel bar is placed in a coil with an alternating current flowing

through it (a solenoid), the varying current and magnetic field will cause the

ends of the bar to vibrate and hence create a sound wave. This is what happens

when the transducer is transmitting.

Type with specs 50 kHz - 100 W: Maximum depth

measurable - 700 metres Type with specs 20 kHz - 100 W: Maximum depth

measurable - 400 metres

The magneto-striction type

would be fitted inside a cast elliptical housing or a circular housing in such

a way that the bottoms of the pistons are in contact with the sea (i.e. pierced

hull type - see details of this type later).

Another type, which is fitted internally, consists of

a ring of thick nickel discs enclosed in a winding to which the AC is applied.

This resulting sound pulse is directed downwards through the steel bottom shell

by a reflector. The advantages of nickel ring types are that it is cheaper to

construct and damping is greater.

In both designs the sound pulses are directed down

wards in a cone shaped beam to avoid loss of sounding when the vessel is

rolling. The process is reversible, as, when the echo returns, it applies a

varying pressure to the working faces of the transducer, which causes the

magnetic condition of the nickel to fluctuate at the same frequency. This

varying magnetic field strength induces a voltage in the winding round each

piston leg and this voltage is amplified before being applied to the indicator.

As oscillators must be in

water dry forepeak tanks. Tanks may be flooded sufficiently

to-keep them submerged. Forepeak tanks are usually arranged so that when they

are pumped out, enough water is retained to keep the oscillators from becoming

dry.

Echo

sounding equipments may be divided into two main classes:

.1 Those that transmit and receive sound vibration through the

shell plating of a ship, referred to as 1nternal installation" class.

.2 Those

that are in direct contact with the sea generally referred to as

"pierced-hull installation" class.

In the internal installation class, because of the

shell plating, energy is wasted during transmission and reception. For a shell

plating thickness of 9.5 mm, about 15 per cent of the energy gets through the

plate and only 2 per cent gets through when the shell plating is 31.8 cm thick.

The advantages of having an internal installation are:

.1 Equipment may be fitted without dry-docking

the ship.

.2 Projectors

or oscillators may be serviced or changed while the ship is afloat.

Sound wave energy is wasted if it is required to pass

through a plate. The plate will prevent sound waves to pass through, if the

thickness of the plate is close to a quarter wavelength of the sound wave; but

if thickness of the plate is about a half wavelength then the steel plate

becomes transparent to the sound wave.

For a pierced-hull installation, the shell plating of

the ship is first pierced and the gap filled in by a thinner plate. If a steel

plate is to be fitted, then the physical dimensions of the steel plate needs to

be small and the plating will have to vary in thickness from ship to ship

because of different frequencies used.

Thus for pierced hull installation the problem of

using a frequency suitable for reasonable penetration no longer applies and

higher frequencies can be used.

With a very low frequency, the size of the oscillator

becomes inconveniently large; secondly, there is lack of selectivity from water

and other noises within the audible range and finally, less directivity.

The higher frequencies gives

more improved selectivity from noise and better directivity is possible, but

there is less penetration.

Echo Sounding - Full cycle of operation

The full cycle of operations for one sounding is as

follows:

The recording stylus starts each cycle as it moves

pass the zero. It triggers an electronic generator, which produces a known

number of electrical oscillations, which are applied to the transmitting

transducer (Tr/Tx). The Tr/Tx

creates the sound pulse, which is injected into the sea, travels to the bottom,

is reflected and returns as an echo to the receiving transducer, where it is

converted back into an electrical pulse. This is amplified and applied to the

stylus, which has moved across the recording paper, to indicate the depth

against a suitable scale. The stylus moves across the paper at a constant speed

which is decided by the designer after he has decided the following:

Maximum depth to be displayed,

Width of the paper and the

SW velocity to be used.

The pulse length to be used for transmission is

governed by a number of factors. The minimum theoretical depth that can be

measured is equal to half a pulse length. Since sound travels at approx. 1500

metres per second, a pulse length of 1 millisec (ms)

will mean that the theoretical minimum depth, which could be measured, would be

1.5 metres. In practice it would be about this value.

The difference between the theoretical and the

practical values is because the transducer being a resonant device does not

stop oscillating immediately the electrical pulse ceases. It shows a tendency

to "ring" when energised and this is usual

for the time taken for 10 to 12 cycles. If depths less than 1.5 m are to be

measured then a shorter pulse length is required. One sounder has a pulse

length of 0.3 m, which gives a theoretical minimum sounding of 0.225 m and a

practical minimum of 0.45 m.

If a very deep measurement is to be made then more

energy is required. This could possible be achieved by increasing the amplitude

of the pulse, but this is usually limited by the output of the active element

in the transmitter and therefore it is injected directly into the water.

Sounders, which have to cover very shallow and very deep sounding on different

ranges, will usually be designed so that the pulse length can be changed as the

range is changed.

PULSE LENGTH

Shallow 0.3

milli sec Up

to 200 or 400 metres

l to 5 milli sec 2000

metres or more

The commonest form of echo sounder has a display,

which records the depth on electro-sensitive paper. It may take the form of

rotating arm moving anti-clockwise across the paper, which is marked by the

stylus at the end of the arm when a DC pulse is applied on receipt of the echo.

Another type has a moving belt to which the stylus is attached and which is

made to move across the paper from top to bottom at a constant rate, which is

decided by the depth scale displayed. The paper is marked in the same way, and

the indicated depth is measured from the top of the paper by a suitable

vertical scale at the side.

Another type of display more suitable for shallow

depths consists of a disc or arm carrying a neon lamp at its extreme edge,

which is spun round at constant speed. A scale is fitted round the edge of the

area covered by the spinning neon which is made to flash at zero on

transmission and again on receipt of the echo at the point in its revolution

appropriate for the depth measured. The overall recording accuracy claimed for

one echo sounder is close to +/- 2% of the actual depth.

Recording Paper may be of two kinds, moist and dry.

The moist paper is impregnated with a solution of potassium iodide and starch.

When a direct current is passed through it from the stylus to the metal plate

at the back, it releases iodine and causes a brown stain to appear. The stylus

is tipped with iridium. This action only takes place when the paper is damp -

it becomes an insulator when dry.

This type of paper should be kept in its airtight tins

before use. If an echo trace on damp paper is to be kept for reporting or other

purposes, a line should be drawn down each side of the paper while it is still damp

to indicate the limits of the scale. The bottom trace and transmission line

should be drawn in pencil, the paper dried, preferably in a dim light, and then

the paper should be rolled up to prevent fading. An indelible pencil should

preferably be used or a ballpoint pen for all writing.

The Dry paper is a carbon impregnated paper base, metallised on one side and covered on the other with a very

thin film of fight coloured semi-conducting chemical. The metallised

side makes contact with the metal plate at the back, and the stylus moves over

the chemically treated side. When the echo returns, a pulse of current is

applied to the stylus which destroys the chemical film and exposes carbon

beneath to show a black record in contrast to the gray paper, carbon dust and

possibly fumes will be released and these may be a health hazard. The recorder

must be sited so that adequate ventilation its

possible. The dust, which is deposited on parts of the recorder must be removed

at require intervals using a soft rag or brush.

TRANSDUCER SITING

Satisfactory operation of an echo sounder depends on

the transmission and reception of the largest possible signal for a given

amount of power. The siting of the transducer is important in this respect to

reduce attenuation on transmission and reception as far as possible. The ideal

position is one in which there is "solid" water free from aeration

beneath the transducer, and where the effects of surface, engine and propeller

noise are at a minimum. There are few positions which are suitable in every

respect and a position found to be satisfactory in one design of ship will not

necessary give equally good results in another.

The principle source of aeration is the bow waves

created by the ship. This wave rises some way up the stem, curls over, and then

is forced down beneath the ship, taking a quantity of air with it.

The resultant bubble stream normally starts about a

quarter length of the ship from the stern, and divides about three quarters of

the length from the bow. The bubble stream varies in form and intensity

according to the speed, draught, shape of bow and hull, the trim of the ship as

well as the sea state. In ships with a bulbous bow the wave appears to dip

water just abaft the stem, so that the flow of bubbles is over almost the whole

length of the vessel and the only satisfactory forward site may be within the

bulb. In oil tankers the after position is invariably chosen, usually under the

fore part of the engine room. Classification Society Lloyd Register does not

permit oscillators to be fitted underneath cargo space on vessels classed for

carrying petroleum in bulk.

A position in the forepeak may appear to be the best,

but in bad weather and light ship it would be unlikely to give good results and

may also be difficult to fit there. In laden ship of normal design a position

about a quarter of the length from the stem will often be found to give

satisfactory results. Ships often making long passages in ballast e.g. tankers,

often find an after position about three quarters of the length from the stem

gives better results. If two are fitted, one is fitted at one quarter and one

at three quarter length abaft the stem.

Care must be taken to make sure a receiving transducer

is a sufficient distance from the propeller, and tests should be carried out to

ensure this. They need to be sufficiently separated to prevent interaction

between them, but the separation should be as small as possible to ensure

accurate sounding in shallow water. Positions either side of the keel is often

satisfactory.

Other factors, which should be borne in mind, are: fit

in a horizontal position, sometimes slightly projecting but faired off to avoid

aeration. Avoid sites near bow thruster units, water intake pipes and

underwater log units.

Internal access to the transducer should be possible

for maintenance. Any junction box should be in a dry space and if possible the

transducer should be in a dry place.

NOISE

All transmission systems are subjected to interfering

signals of some kind.

CROSS NOISE

It is caused by vibration of the energy, which is

transmitted out by a ship and goes directly to the echo sounder receiver. The

recorder shows a broad line on zero reading and this can mask echoes totally.

THERMAL NOISE

It is generated in electronic devices by random movement

of electrons in components and this is amplified in the receiver in any radio

system. In sonar system, using sonic waves below 50 kHz, noise level can

usually be ignored, as it is very small compared with the sea noise.

SEA NOISE

They are of two main kinds, the first are interfering

wave action, and may be thought of as background noise. Sources are fish, other

ships, and noise from one's own ship particularly in bad weather and close to

land. For most purpose, the amplitude of disturbances at any instances is

unpredictable and taken, as a whole may be considered random. For this reason,

the designer must make sure that the signal is always recognisable

above the noise level.

The second is noise produced by the interaction of the

sea and the sonar system. This is generally called "reverberation

noise" and when transmitted into water, all the small reflectors in the

water such as bubbles, marine life, and mud and sand particles immediately

affect it.

These multiple reflector produces a return signal (echo),

which is theoretically continuous since they exist at all depths. However the

intensity of the transmitted pulse is reduced as it moves away from the

transducer and the intensity of the return signal also reduces in accordance

with the same law. The result is that after the end of transmission, the

reverberation signal decreases with time according to an inverse square law.

Its effect can be considerably reduced by the use of time variable gain or

"initial suppression". This circuit is set to reduce the gain of the

receiver to a very low level immediately following transmission, but then

allows the gain of reverberation noise after the same has fallen below that of

background noise.

Interpretation of Sounding

False Bottom Echoes. Second

Trace Echoes

Echoes, which are received at a properly adjusted

sounder, until after the stylus has completed one or more passes across the

paper and the next pulse have been, transmitted cause false readings. Example

of one revolution represents 1600 metres, and an indicated depth of 50 metres

could be sounding of 50 or 1650 or even 3250 metres. The correct depth can be

ascertained if the transmission circuit can be switched off with the stylus

still moving. After switching off, on the switch and then count the number of

times the stylus crosses the paper before the echo re-appears.

Reflection echoes

a) Double Echoes

Echoes received after reflection from the seabed, but

which the hull or the sea surface back to the bottom and then reflects thence

to the transducer. They produce a second weaker echo at approximately double

the correct depth. It will fade out if sensitivity is reduced (may be received

up to several hundreds metres).

b) Multiple Echoes

Echoes received after being reflected several times

between the seabed and the surface or the ship's bottom before the energy is

lost. It causes equally spaced echoes on the trace. Reduce sensitivity to fade

out. Switch on to first phase and then phase deeper to locate first echo.

c) Variable Echoes

These are varying reflecting surfaces on the seabed.

In general hard sand, coral, chalk and rock are good reflectors and thick mud

is a poor reflector. Stepped formation of rock result in side Echoes from an

object not immediately below the vessel but whose slant depth is less than the

depth of water.

d) Electrical faults, or man made noises.

Other False Echoes

These do not normally obscure the bottom echo and may

be caused by

.1 Shoals

of fish

.2 Layers

of water of differing sounding velocities (salinity etc.)

.3 The

deep scattering layer, which is a layer or set of layers, in the ocean,

believed to consist of plankton and which attenuate, scatter and reflect sound

pulses. They lie between about 300-450 metres below the surface by day, and

near the surface between sunset and sunrise (by day, it is more pronounced when

the sky is clear, than when overcast).

.4 Kelp or weed.

.5 Turbulence from the interaction of tidal streams or

eddies with solid particles in suspension.

SPEED ERROR

The speed of the recorder motor must be proportional

to the velocity of sound in seawater and the velocity is known to vary. The

recorder motor running at an incorrect speed causes the speed error. If the

motor speed is too fast, it will record a greater depth and if it is too slow

than a lesser depth.

Other errors include Pythagoras error, error due to

maladjustment, ECHO SOUNDER CONTROLS

Mains

Dimmer

Range/Phasing/ scale

Gain

Other controls

Speed control

Zero adjustment/Draught setting

Change over transducer

Minimum depth alarm

PULSE length

Number of pulses per sec.

Checks on echo sounders

Twice yearly with hand lead, if reading is too high,

then motor is going too fast.

ERRORS

Velocity Error - Increase in temperature and salinity

of water increases velocity of sound in water thus giving rise to an error in

the depth displayed.

Aeration Presence of air bubbles below the

transducer gives rise to false echoes. Air bubbles are normally caused when a

vessel goes astern, turbulence when rudder is put hard over or due to pitching

when vessel is in light condition.

Multiple echoes This is caused in shallow waters

with a rocky bottom due to some of the sound pulses reflecting up and down

between the ships keel and the sea bottom before being recorded on the

display. The first echo is the correct reading.

False echoes In deep waters, by the time the sound

pulse returns from the bottom, the stylus may have already finished more than one revolution and thus the

echo which will be recorded will be a false one and the depth indicated will be

much lower than the actual depth.

Pythagoras Error If the vessel has one transducer

for transmitting and one transducer for receiving, separated by some distance,

the distance travelled by the pulse will be greater

than the depth of the sea bed in shallow waters.

MISCELLANEOUS

Comply with the maintenance instructions given in the

manual. Normally it is just a monthly

cleaning of carbon / dirt deposits from the inside of the recorder.

Keep a stock of at least 1 spare stylus and 3 months

stock of recording paper.

Compare the soundings obtained with the soundings

given in the chart.

Maintain a log to enter the soundings obtained.

Some echo sounders have an alarm to alert the

navigator when the sounding goes below the set sounding.