| Controls | Display | Errors | Antenna | Plotting |

RADAR

CRT

THE CATHODE-RAY TUBE (CRT)

The cathode-ray tube (CRT) and the picture tube of a

television set are one and the same.

All CRT’s have three main elements: an electron gun, a deflection system, and a

screen.

The electron gun provides an electron beam, which is a

highly concentrated stream of electrons. The deflection system positions the

electron beam on the screen, and the screen displays a small spot of light at

the point where the electron beam strikes it.

THE ELECTRON GUN

The cathode of the electron gun in the CRT is required

not only to emit electrons, but also to concentrate emitted electrons into a

tight beam.

The cathode of the CRT consists of a small diameter

nickel cap. The closed end of the cap is coated with emitting material.

CRT cathode.

Because of this type of construction, electrons can only be emitted in one direction. Notice that the emitted electrons are leaving the cathode at different angles. If these electrons were allowed to strike the screen, the whole screen would glow.

Since the object of the electron gun is to concentrate

the electrons into a tight beam, a special grid must be used.

This special grid is in the form of a solid metal cap

with a small hole in the centre.

The grid is placed over the emitting surface of the

cathode and charged negatively in relation to the cathode.

The dotted lines represent the direction of cathode

emitted electron repulsion, as shown in the figure:

Operation of the CRT grid.

Since all emitted electrons leave the cathode (point

C), their paths can be identified. An electron attempting to travel from point

C to point B (downward) will instead follow the path from point C to point E to

point P.

Consider an electron leaving from C in the direction

of point A (upward). Its path will be curved from point C to point P by

electrostatic repulsion.

These curving electron paths are due to the negative

potential of the grid coupled with the high positive potential of the anode.

The potential of the anode attracts electrons out of the cathode-grid area past

point P toward the screen.

The grid potential may be varied to control the number

of electrons allowed to go through the control-grid opening. Since the

brightness or intensity of the display depends on the number of electrons that

strike the screen, the control grid is used to control the brightness of the

CRT.

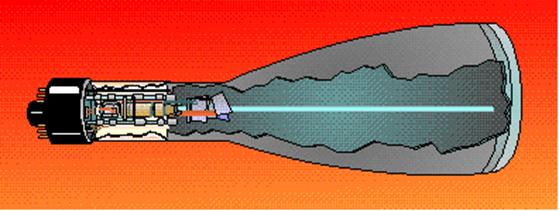

Electron-beam formation In a CRT.

The proper name, BRIGHTNESS CONTROL, is given to the

potentiometer used to vary the potential applied to the control grid. The

control grid actually serves as an electron lens. It is this electronic lens

that is adjusted when the brightness control is turned on, on the Radar set.

Notice that the effect of the grid is to focus the electron beam at point P. After passing point P, the electrons start to spread out, or diverge, again. Therefore, it becomes necessary to provide some additional focusing to force the electrons into a tight beam again.

This is done by two additional positively charged

electrodes as shown in figure. The first electrode is commonly called the

FOCUSING ANODE.

Generally, the focusing anode is charged a few hundred

volts positive with respect to the cathode. Electrons emitted by the cathode

are attracted to the focusing anode. This is the reason that they travel through

the small hole in the grid.

The second electrode, called the ACCELERATING ANODE,

is charged several thousand volts positive in relation to the cathode. Any

electrons approaching the focusing anode will feel the larger electrostatic

pull of the accelerating anode and will be bent through the opening in the

focusing anode and will travel into the area labelled

D.

You might think that once an electron is in this

region, it is simply attracted to the accelerating anode and that is the end of

it. This does not happen. Because the accelerating anode is cylindrical in

shape, the electrostatic field radiating from it is equal in all directions.

Thus, an electron is pulled in all directions at once, forcing the electron to

travel down the center of the tube.

Then, the electron is accelerated into the

accelerating anode. Once it passes the mid-point (point E), it feels the

electrostatic attraction from the front wall of the accelerating anode, which

causes it to move faster toward the front. Once the electron reaches point F,

equal electrostatic attraction on either side of the opening squeezes it

through the small opening in the front of the anode.

From there, it is joined by millions of other

electrons and travels in a tight beam until it strikes the screen (point S).

THE CRT SCREEN

The inside of the large end of a CRT is coated with a

fluorescent material that gives off light when struck by electrons. This

coating is necessary because the electron beam itself is invisible. The

material used to convert the electrons’ energy into visible light is a

PHOSPHOR.

Many different types of phosphor materials are used to

provide different colored displays and displays that have different lengths of

PERSISTENCE (duration of display).

However the CRT suffers from the effects of secondary

emission. In order to reach the screen, electrons from the cathode are

accelerated to relatively high velocities. When these electrons strike the

screen, they dislodge other electrons from the material of the screen. If these

secondary emission electrons are allowed to accumulate, they will form a

negatively-charged barrier between the screen and the electron beam, causing a

distorted image on the CRT screen.

Therefore a special coating called an AQUADAG COATING

is applied to the inside of the tube. This coating is composed of a conductive

material, such as graphite, and has the same high-positive potential applied to

it that is applied to the accelerating anode. This allows the aquadag to perform two functions.

First, since the aquadag coating

is positive, it attracts the secondary emitted electrons and removes them.

Second, because the aquadag

is operated at a high-positive potential and is mounted in front of the

accelerating anode, it aids in the acceleration of electrons toward the screen.

Aquadag coating in a CRT.

To review the above:

Electrons are emitted from a specially constructed

cathode and move toward the front of the CRT. The number of electrons that

leave the area of the cathode is determined by the cap-shaped grid. In

addition, the grid concentrates the emitted electrons into a beam.

The electron beam is focused and accelerated toward

the screen by two electrodes:

The focusing anode and

The acceleration anode.

The electron beam strikes the screen and causes a

bright spot to appear at the point of impact. Any electrons released by

secondary emission are removed from the tube by the aquadag

coating.

DEFLECTION

At this point, you have a bright spot in the center of

the CRT screen. For the CRT to work properly, the spot must be moved to various

positions on the screen. Because the beam is swept very quickly across the CRT

and the phosphor continues to glow for a short time after the beam has moved

on, you do not see a series of lines, but a continuous picture.

Impact of an electron beam

on a CRT screen.

Electrostatic Deflection

There are two ways to move an electron (and thus an

electron beam):

Either with a magnetic or

With an electrostatic field.

Because of this, there are three possible ways to move

or deflect an electron beam in a CRT: magnetically, electro magnetically, and

electro statically.

All three ways are used in electronics. In general,

though, electrostatic and electromagnetic deflections are used most often.

A TV set as well as a Raster scan Radar, for example,

uses electromagnetic deflection, while much of the traditional radar’s use

electrostatic deflection.

ELECTROSTATIC DEFLECTION

Here the electron is travelling between two charged

plates, H1 and H2. As can be seen, before the electron reaches

the charged plates, called DEFLECTION PLATES, its flight path is toward the

center of the screen.

In view B, the electron has reached the area of the

deflection plates and is attracted toward the positive plate, H2,

while being repelled from the negative plate, H1.

As a result, the electron is deflected to the right on

the inside of the screen.

When viewed from the outside of the CRT, the view

would be as ‘C’.

But to be useful, this spot will have to be converted

to a bright line, called a sweep, across the face of the CRT screen.

Horizontal deflection.

In view A, five electrons are emitted in sequence, 1

through 5, by the electron gun. The right deflection plate, H2, has

a large positive potential on it while the left plate, H1 has a

large negative potential on it.

Thus, when electron 1 reaches the area of the

deflection plates, it is attracted to the right plate while being repelled from

the left plate.

In view B, electron 2 has reached the area of the

deflection plates. However, before it arrives, R1 and R2 are adjusted to make

the right plate less positive and the left plate less negative.

Electron 2 will still be deflected to the right but

not as much as electron 1.

In view C, electron 3 has reached the area of the

deflection plates. Before it gets there, R1 and R2 are adjusted to the

mid-point. As a result, both plates have 0 volts applied to them.

Electron 3 is not deflected and simply travels to the

center of the CRT screen.

In view D, electron 4 has reached the area of the

deflection plates. Notice that R1 and R2 have been adjusted to make the right

plate negative and the left plate positive. As a result, electron 4 will be

deflected to the left.

Finally, in view E, the left plate is at its maximum

positive value.

Electron 5 will be deflected to the extreme left.

Thus what you will see when you are facing the CRT is

a bright luminous line, as shown in view E. While this description dealt with

only five electrons, in reality the line across a CRT face is composed of

millions of electrons.

Instead of seeing five bright spots in a line, you

will see only a solid bright line.

In summary, the horizontal line displayed on a CRT is

made by sweeping a stream of electrons rapidly across the face of the CRT. This

sweeping action, or scanning, is performed by rapidly varying the voltage

potential on the deflection plates as the electron stream passes.

Vertical Deflection

This is done by using a second set of deflection

plates called VERTICAL-DEFLECTION PLATES.

Arrangement of deflection plates in a CRT, front view.

In normal usage, the horizontal plates sweep a straight line of electrons across the screen from left to right while the signal to be displayed is applied to the vertical deflection plates.

Notice T1; the output of this transformer is applied to the vertical-deflection plates. The signals applied to the vertical plates are 180° out of phase with each other. Thus, when one plate is attracting the electron beam, the other will be repelling the electron beam. Because you are only concerned with what happens inside the CRT, this circuitry will be eliminated and only the CRT and its deflection plates will be shown, as in view B.

Vertical deflection in a CRT.

Now look at view C. While this illustration looks

complicated, don’t let it worry you. You have already analyzed more complicated

diagrams. The sine wave in the center of the screen is the signal that will be

displayed as a result of the two 180° out-of-phase sine waves applied to the

vertical-deflection plates. The five spots on the center sine wave represent

the five electrons used to explain horizontal deflection. Only now these

electrons will be deflected both vertically and horizontally. Time lines T1

through T5 represent the time when each like-numbered electron reaches the area

of the deflection plates. Because you already know how the electron beam is

swept or deflected horizontally, we will not discuss horizontal deflection.

Just remember that from T1 to T5, the electron beam will be continuously moved

from your left to your right. Now that you know where everything is on the

illustration, you are ready to discover how a sine wave is displayed on a CRT.

At time 1 (T1), the sine waves applied to both

vertical-deflection plates are at their null points, or zero volts. As a

result, electron 1 is not vertically deflected and strikes the CRT at its

vertical center. At time 2 (T2), the sine wave applied to the top plate is at

its maximum negative value. This repels electron 2 toward the bottom of the

CRT. At the same time, the sine wave applied to the bottom plate is at the most

positive value, causing electron 2 to be attracted even further toward the

bottom of the CRT. Remember, the beam is also being moved to the left. As a

result, electron 2 strikes the CRT face to the right of and below electron 1.

At time 3 (T3), both sine waves applied to the vertical-deflection plates are

again at the null point, or zero volts. Therefore, there is no vertical

deflection and electron 3 strikes the CRT face in the center of the vertical

axis. Because the electron beam is still moving horizontally, electron 3 will

appear to the right of and above electron 2. At time 4 (T4), the sine wave

applied to the top vertical-deflection plate is at its maximum positive value.

This attracts electron 4 toward the top deflection plate. The upward deflection

of electron 4 is increased by the negative-going sine wave (at time 4) applied

to the bottom deflection plate. This negative voltage repels electron 4 upward.

Thus, electron 4 strikes the CRT face to the right of and above electron 3. Finally, at time 5 (T5) both input sine waves are again at zero

volts. As a result, electron 5 is not deflected vertically, only

horizontally. (Remember, the beam is continually moving from right to left.)

While this discussion is only concerned with five

electrons, vertical scanning, or deflection, involves millions of electrons in

a continuous electron beam. Instead of seeing five spots on the CRT screen, you

will actually see a visual presentation of the sine wave input.

The field of electronics is in a constant state of evolution. Transistors replaced most vacuum tubes. Transistors were replaced by integrated circuits (ICs). Of all the tubes discussed, the CRT is the least likely to be replaced in the near future.