| Load Lines | Rudder & Propeller |

Ship Construction

Ship Dimensions and Form

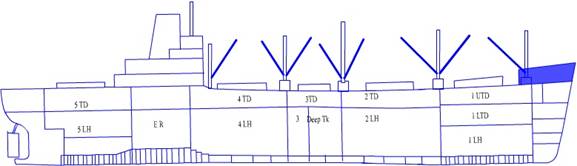

General Cargo Vessel

These types

of ships in general are built with longitudinal framing at the decks and in the

double bottoms. Transverse framing is at the sides.

Profile

The

transverse strength is given by fitting transverses at the deck and plate

floors are fitted in the double bottoms.

Longitudinal

framing is not usual in general cargo vessels due to the high broken stowage

involved. Also deep transverses then have to be fitted about 3.7 metres to give

the ship transverse strength.

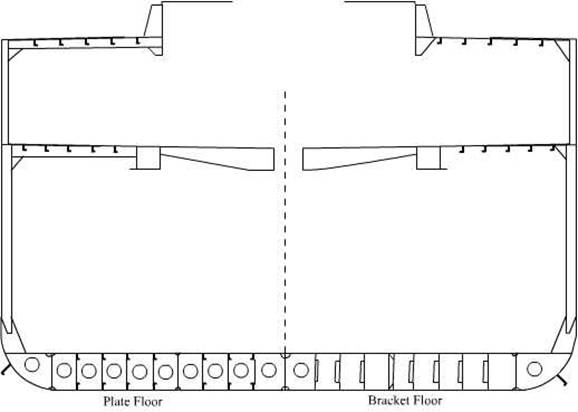

Bilge wells

are fitted with a cubic capacity of 0.17 cbm. Nowadays ceiling on top of tank

tops are generally not fitted as such the plating is increased by 2mm. However

where ceiling is fitted they should be removable in sections. The ceiling where

fitted should have a clear space for drainage at least of 12.5mm.

Cargo

battens are fitted to the sides and to the turn of the bilges – size of 50mm

thick and spacing between rows of 230mm.

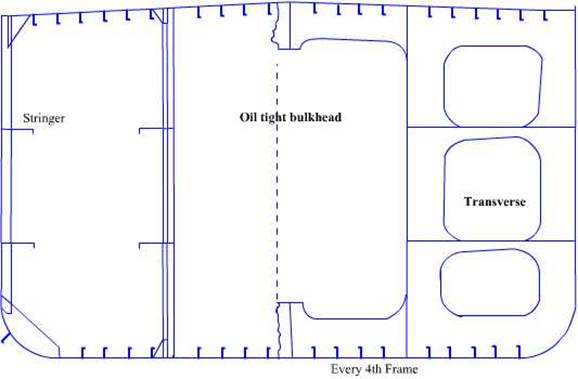

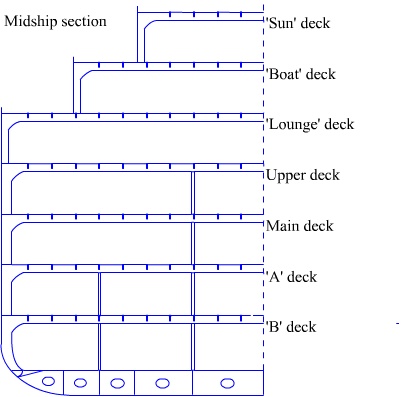

Midship

Shown above

is a centre line bulkhead in the lower hold and in the tween deck. This extends

from the transverse watertight bulkhead to the hatch coamings.

Tankers

These ships

may have two or more longitudinal bulkheads – today with double hull concept at

least 3 but normally 4.

The bottom

and deck are also framed longitudinally and so are the sides and the sides of

the longitudinal bulkheads.

The length

of a tank is not to exceed 0.2L. As the size of the tanker grows transverse

wash bulkhead are fitted at about mid length of the tank. These are for size of

tanks over 0.1L or 15m whichever is more.

Centre line

was bulk heads are fitted where the breadth exceeds the dimensions as laid out

in the Rules for different size of tanks.

Cofferdams

are provided both forward of the oil carrying space as well as in from of the

ER bulkhead. Generally the pumproom is located within the cofferdam aft. Some

ships have a forward pump room located in the forward cofferdam.

The

cofferdams are to be at least 760mm in length

Some

smaller ships have a combined transverse and longitudinal framing system.

In lieu of

bulwarks these ships are to have open rails on deck.

Cargo tanks

are tested by a head of water in the cargo tank – 2.45m above the highest point

of the tank.

Generally a

system of staggered test is undertaken. Alternate tanks are filled and the

empty tanks is inspected. Once all the empty tanks are

inspected, the filled tanks are empties and the reverse tanks are filled and

the other alternates inspected.

Inspecting

of the tank welding are done by rafting within a tank.

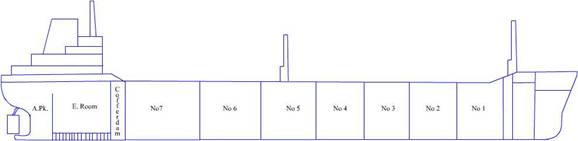

Profile

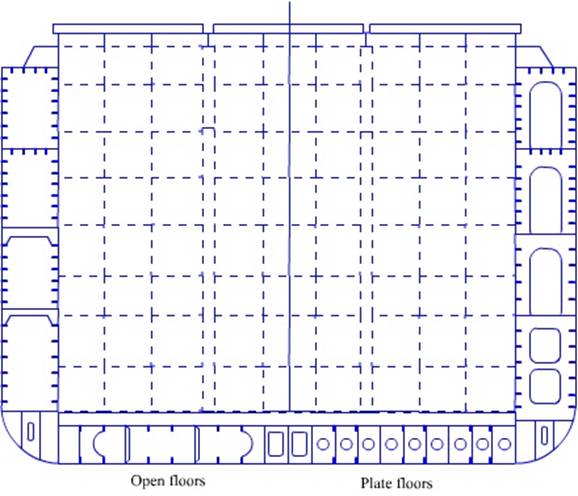

Plan

Midship

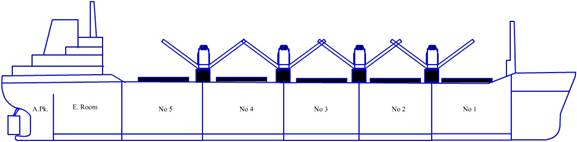

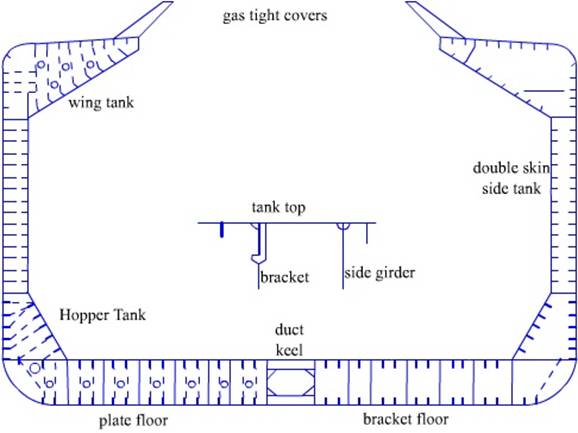

Bulk Carriers:

These ships

are characterised by their ability to carry cargo in bulk. If carrying grain

and other lighter cargo all the holds are filled.

However if

heavy cargo such as iron ore is carried then alternate holds are filled and to

the designed loads only.

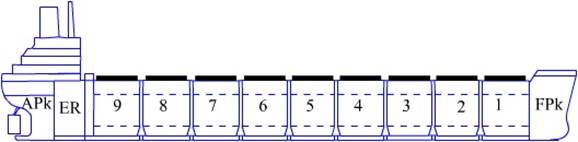

Profile

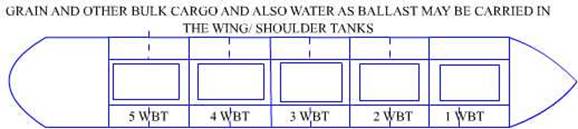

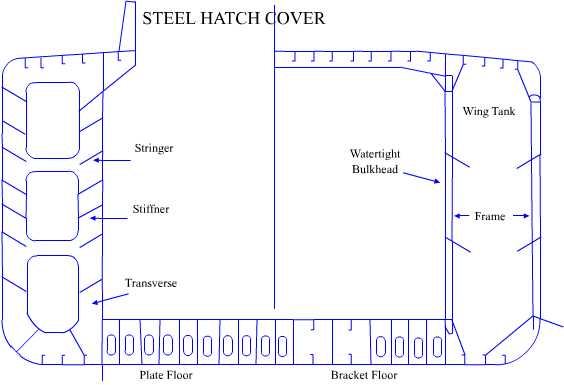

The vessel

may be constructed on the combined system, longitudinal framing together with

transverse framing which are fitted at the sides. The longitudinal framing is

fitted in the double bottoms, the deck and the bottoms of the wing tanks.

The wing

tanks may be utilised to carry cargo as well as remain empty. They carry

ballast water during the ballast passage.

Transverse

webs are fitted at in the wing tanks at intervals as laid out in the Rules. And

side stringers are fitted at about 1/3rd and 2/3rd the

depth of the tanks.

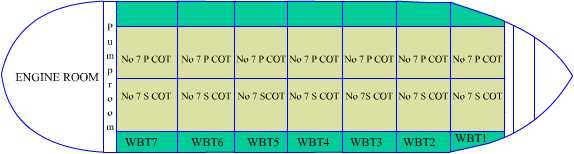

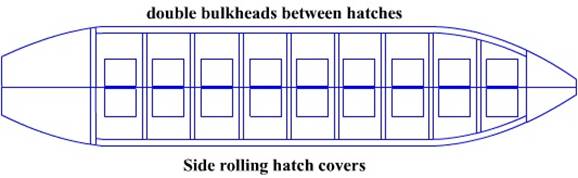

Plan

Midship

Combination Carriers:

These ships

are capable of carrying ore as well as oil in bulk.

Transverse

bulkheads are usually of the cofferdam type with all the stiffening on the

inside.

There is a

rise of floor of the inner bottom which facilitates drainage to the drain well

arranged on the centre line. The pipelines run through a duct keel. The duct

keep entrance in the pumproom has a oil and gas tight

door.

Profile

On the top

the hatch covers are mainly the side rolling Macgregor type.

The hatch

breadth is usually about 50% of the breadth of the beam. The main disadvantage

of this type of ship is the stability – since they are not built with a

longitudinal partition in the centre the free surface effect is enormous and

this necessitates overall loading complexities.

Plan

Together

with this is the sloshing effect which tend to damage

the fitting inside.

The

stability book would give the loading levels as well as the loading stability

requirements as per the Rules.

Midship

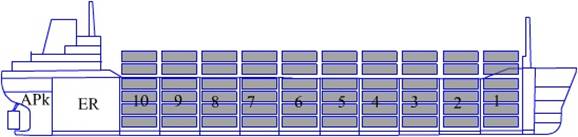

Container:

Longitudinal

framing is used throughout the main body length of the ship. Transverse framing

is used on the fore part and the after part.

Profile

The ships

are built having a cellular construction at the sides. Strong longitudinal box

girders are formed port and starboard by the upper deck – the second deck – top

of the shell plating and top of the longitudinal bulkhead. The upper deck and

the sheer strake form the box girder. These girders also provide stiffness

against racking stresses and used as water ballast tank spaces.

Midship

A form of

bulkhead is fitted at intervals, centre to centre with water tight bulkheads

being fitted as required by the Rules. The bulkhead gives support to the double

bottom structure.

The

container guides consist of angle bars about 150mm x 150mm x 14mm thick

connected to vertical webs and adjoining structure spaced 2.6m apart. The

bottom of the guides is bolted to brackets welded to the tank top and beams.

The brackets are welded to doubling plates, which are welded to the tank top.

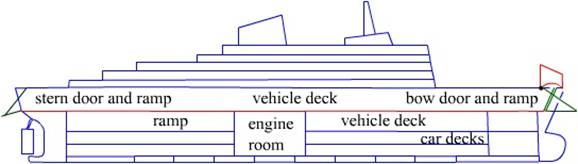

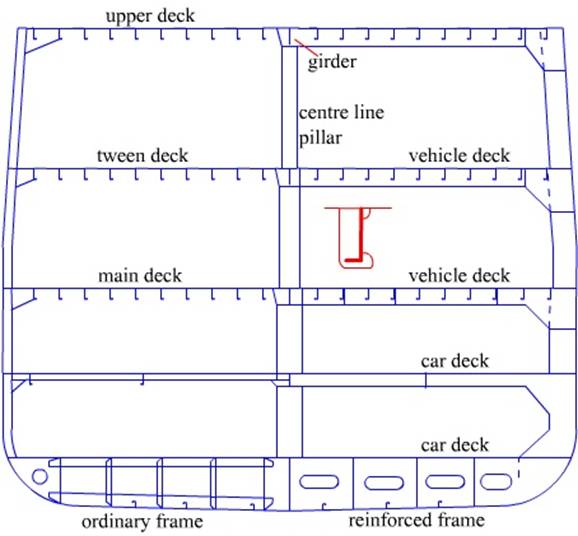

Ro – Ro

Roll on Roll off ships have generally two ramps at

either end of the ship to facilitate the loading of vehicles.

The main

characteristic of these types of ships is the clear decks un

interrupted by transverse bulkheads. Deck heights are sufficient to accommodate

the various types of vehicles carried.

Profile

The lower

decks may be used for carriage of cars while the upper may be used for the

carriage of bigger vehicles.

Transverse

strength is maintained by fitting deep closely spaced web frames in conjunction

with deep beams. These are usually fitted every 4th frame and about

3 m apart.

The lower

decks which are divided by watertight bulkheads have hydraulically operated

sliding bulkhead doors which are opened while working cargo in port.

The deck

thickness is increased to take the concentrated loads; a reduction in the

spacing of the longitudinals with an increase in size. A centre line row of

pillars is fitted.

Ramps are

fitted at the bow and at the stern to facilitate the loading and discharging of

vehicles. The separate decks are reached by fixed and sometimes hydraulically

operated foldable operated ramps.

A service

car is provided within the ship to transfer the lashing gear to the different

decks.

Midship

The stern

ramps are generally set at an angle to the ships centre line to ensure that the

ship can work cargo in any berth.

Passenger:

The basic construction of these vessels follows the

dry cargo vessel in their detail, a large number of decks being fitted.

Profile

Each passenger ship is differently built with the

naval architects and the classification societies agreeing on the various

additions to the various pillars and bulkheads.

However the basic rule and the provisions of SOLAS,

MARPOL are complied with.

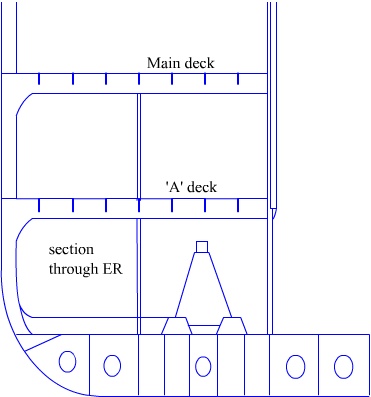

Midship

Midship in way of ER

Definitions

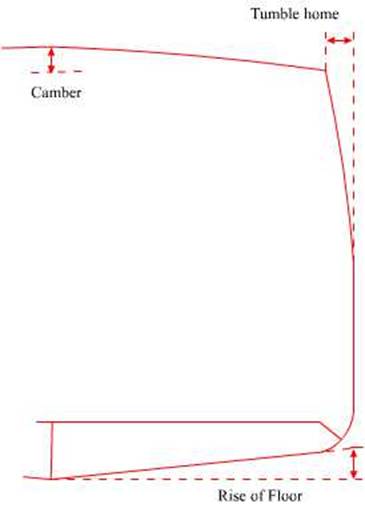

Camber

The purpose

of rounding the beam is to ensure a good drainage of the water and also to

strengthen the upper deck and the upper flange of the ship girder against

longitudinal bending stresses- especially the compression stresses.

Rise Of Floor

This is the distance from the ‘line of floor’ to the

horizontal, measured at the ship side. Purpose basically is to allow drainage

of the double bottom water/ oil to the centre line suctions.

Tumblehome

This is the inward slope of the side plating from the

water line to the upper deck – today ships generally do not have a tumblehome.

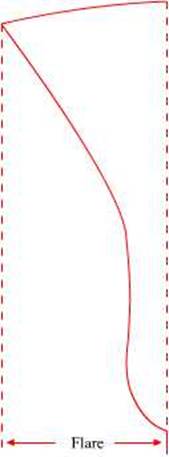

Flare

This is the curvature of the side plating at the

forward and gives additional buoyancy and thus helps to prevent the bows from

diving too deeply into the water when pitching.

The anchors are also clear when lowered from the flare

of a ship.

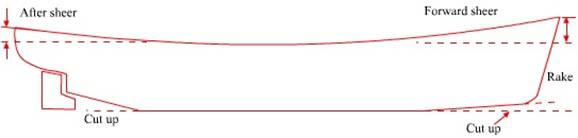

Sheer

This is the rise of ships deck fore and aft. This

again adds buoyancy to the ends where it is needed during pitching. For

calculating the freeboard a correction is applied for the sheer. In modern ship

the after sheer has been greatly reduced.

Rake

This is the

slope, which the forward end has with between the bottom plating and the upper

deck. The length between perpendiculars and the length overall difference is

mostly due to the rake forward. It helps to cut the water and thus adds to the

ships form.

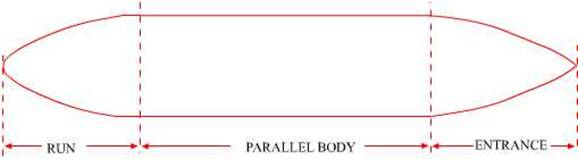

Parallel Middle Body

This is the part of the main body of the ship and it

is a box like structure enabling maximum cargo carrying capacity. It also helps

in the pushing when tugs are used to assist the vessel in berthing. Cargo

stowage is also greatly facilitated.

Entrance

This part is the fore end of the ship and helps give

the box like mid length a ship shaped structure.

Run

The after part similarly to the fore part entrance

helps in giving the box like mid length a ship shaped structure and thus the

handling of the vessel is enhanced.

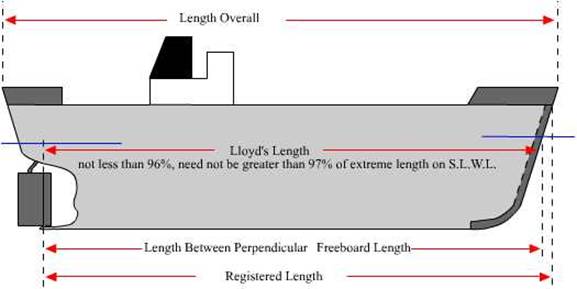

“Length” means 96 per cent of the total length on a

waterline at 85 per cent of the least moulded depth measured from the top of

the keel, or the length from the fore side of the stem to the axis of the

rudder stock on that waterline, if that be greater. In ships designed with a

rake of keel the waterline on which this length is measured shall be parallel

to the designed waterline.

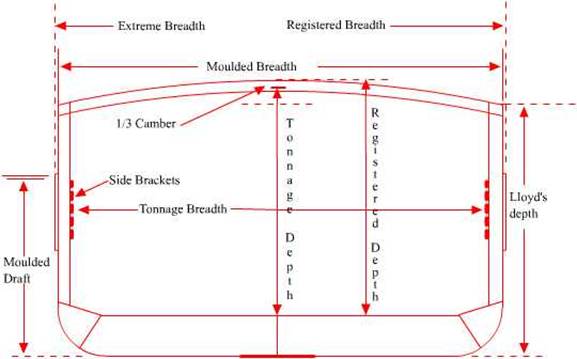

Moulded breadth: is the greatest moulded breadth –

measured inside plating.

Breadth (B) is the greatest moulded breadth of the ship at or

below the deepest subdivision load line.

Draught (d) is the vertical distance from

the moulded baseline at midlength to the waterline in question.

Depth and the draught both are measured from the top

of the keel. The depth is measure from the top of the deck beam. If there is a

camber then allowance is given as 1/3 rd of the camber.

The rest of the meanings are all

self-explanatory.

Definitions

Forward

perpendicular

This is represented by a line, which is

perpendicular to the intersection of the designed load water-line with the

forward side of the stem.

After

perpendicular

A line represents this, which is

perpendicular to the intersection of the after edge of the rudderpost with the

designed load water line. This is the case for both single and twin-screw

ships. For some ships having no rudderpost, the after perpendicular is taken as

the centre-line of the rudderstock.

Length

between perpendiculars

This is the horizontal distance between

the forward and after perpendiculars.

Length

on the designed load waterline

This is the length, as measured on the

water-line of the ship when floating in still water in the loaded, or designed,

condition.

Length

overall

This is the length measured from the

extreme point forward to the extreme point aft.

Base

line

This represents the lowest extremity of

the moulded surface of the ship. At the point where the moulded base line cuts

the midship section a horizontal line is drawn, and it is this line, which acts

as the datum, or base line, for all hydrostatic calculations. This line may, or

may not, be parallel to the load water line depending on the type of ship.

Moulded

depth

This is the vertical distance between the

moulded base line and the top of the beams of the uppermost continuous deck

measured at the side amidships.

Moulded

beam

This is the maximum beam, or breadth, of

the ship measured inside the inner shell strakes of plating, and usually occurs

amidships.

Moulded

draught

This is the draught measured to any

water-line, either forward or aft, using the moulded base line as a datum.

Extreme

beam

This is the maximum breadth including all

side plating, permanent fenders etc.

Extreme

draught

This is obtained by adding to the draught

moulded the distance between the moulded base line and a line touching the

lowest point of the underside of the keel. This line is continued to the FP and

AP, where it is used as the datum for the sets of draught marks.