| Load Lines | Rudder & Propeller |

Ship Construction

Rudder and Propellers

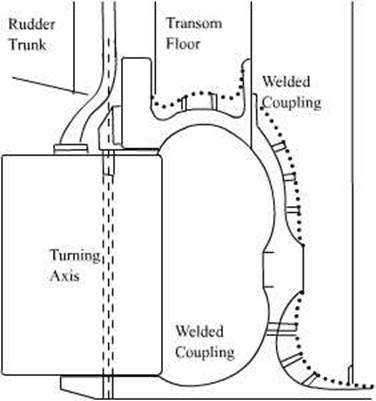

The shape of a rudder plays an important part in its

efficiency. The area of the rudder is approximately 2% of the product of the

length of the ship and the designed draught.

Since the vertical dimensions of the rudder are

somewhat restricted due to the area constraint as mentioned above, the fore and

aft dimensions are increased.

Again due to this increased dimensions the torque

necessary to turn this rudder is overcome by fitting balanced or semi balanced

rudders. Such a rudder has about 1/3rd of the rudder area forward of

the turning axis.

An ideal rudder is one where the centre of pressure

and the turning axis coincide for all angles of the helm.

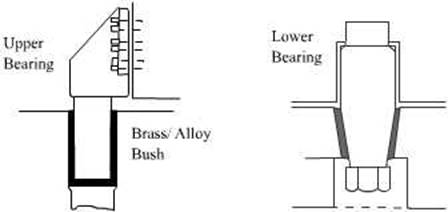

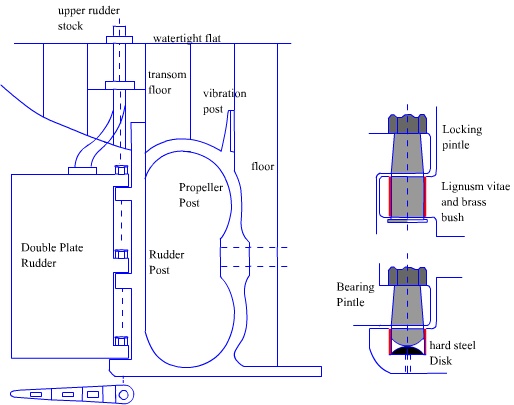

An unbalanced rudder consists of a number of pintles and gudgeons, the top pintle being the locking pintle which prevents any vertical movement in the rudder and the pintle And gudgeon taking the weight of the rudder.

Principle of screw propulsion

Some people still occasionally refer to the propeller

as the “airscrew”, a very accurate and descriptive term that reflects the basic

design and function of the propeller.

Leonardo da Vinci had proposed the concept of a

“helical screw” to power a machine vertically into the air.

The propeller uses that principle to provide

propulsion through the air, much like a threaded screw advances through a solid

medium, with some notable exceptions, primarily related to the loss of forward

movement because the medium is not solid.

Nonetheless, the propeller is similar to a screw in

some common features. First, the pitch

of a propeller is the theoretical distance the propeller would move forward in

one revolution (similar to a screw) and conceptually is the same as the pitch

of a screw, namely the distance between threads if the propeller were a

continuous helix.

The second feature that relates to its screw design is

that the angle of the blade changes along the radius, so that close to the hub,

the angle is very steep and at the tip of the blade it is much more shallow.

From a practical standpoint, this means that unless

the pitch for a given propeller is known, it requires a trigonometric

calculation to determine the pitch empirically.

Thirdly, just as screws come in left hand and right

hand threads, propellers have the same designation. When facing the

water/ air flow if the top of the propeller moves to the right, it is

designated “Right Hand” and if to the left it is “Left Hand”. (As

viewed from the front a right hand propeller turns counterclockwise and a left

hand propeller turns clockwise.) Propellers will frequently be stamped as

“RH” or “LH”.

Propeller and some definitions

Boss or Hub

The central portion of a

screw propeller to which the blades are attached and through which the driving

shaft is fitted.

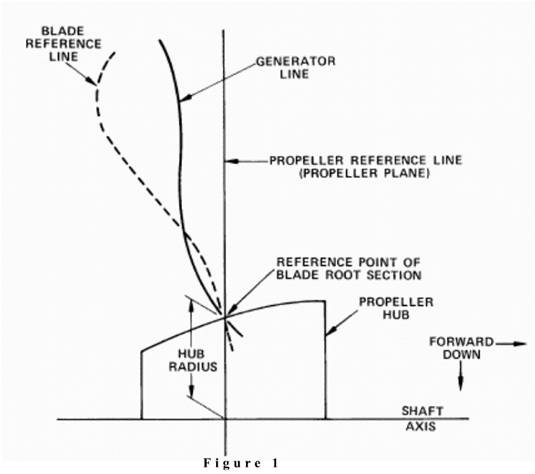

Rake

The point displacement, from

the propeller plane to the generator line in the direction of the shaft axis. Aft

displacement is considered positive rake (see Figure 2). The rake

at the blade tip or the rake angle are generally used as measures of the

rake. The strength criteria of some classification societies use other

definitions for rake.

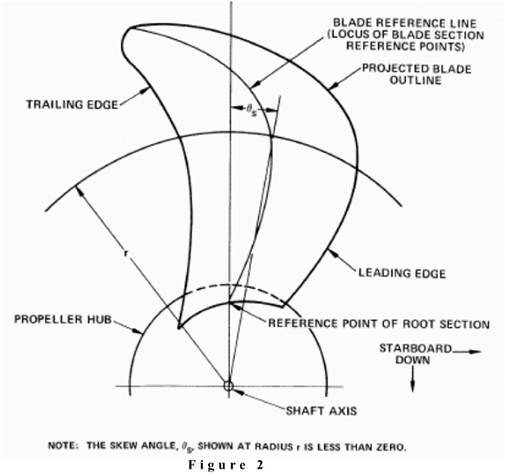

Skew

The displacement of any blade section along the pitch

helix measured from the generator line to the reference point of the section

(see Figure 2). Positive skew- back is opposite to the direction of ahead motion of the blade section. The skew definition

pertains to midchord skew, unless specified

otherwise.

Back (of

blade)

The side of a propeller

blade which faces generally in the direction of ahead motion. This side

of the blade is also known as the suction side of the blade because the average

pressure there is lower than the pressure on the face of the blade during

normal ahead operation.

Tip

The maximum reach of the

blade from the center of the propeller hub. It

separates the leading edge from the trailing edge.

Radius

Radius of any point on a

propeller.

Pitch

The pitch

of a propeller is the theoretical distance the propeller would move forward in

one revolution (similar to a screw) and conceptually is the same as the pitch

of a screw, namely the distance between threads if the propeller were a

screw. For this reason, propellers will frequently be stamped with a

designation such as “D 2550/P2610”. This means that the diameter (in this case

length of propeller or thickness of a screw) is 2.550 meters, and the

pitch is 2.610 meters, so that in a mathematical sense, one revolution of this

propeller would move it forward a distance of 2.610 meters.

Comparing

fixed‑pitch with controllable‑pitch propellers

Advantages

of a controllable pitch propeller

Allow greater manoeuvrability

Allow engines to operate at optimum revs

Removes need for reversing engines

Reduced size of Air Start Compressors and receivers

Improves propulsion efficiency at lower loads

Disadvantages

Greater initial cost

Increased complexity and maintenance requirements

Increase stern tube loading due to increase weight of

assembly, the stern tube bearing diameter is larger to accept the larger

diameter shaft required to allow room for Oil Tube

Lower propulsive efficiency at maximum continuous

rating

Prop shaft must be removed outboard requiring rudder

to be removed for all prop maintenance.

Increased risk of pollution due to leak seals

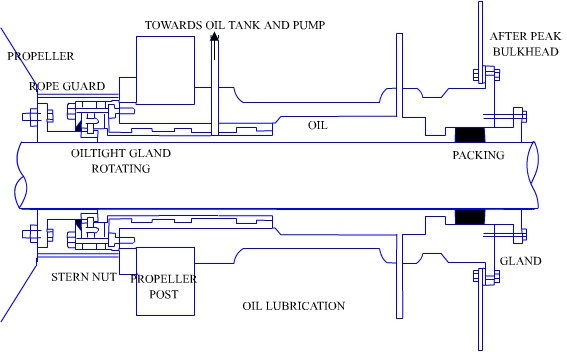

Sketches

the arrangement of an oil‑lubricated sterntube

and tailshaft

Stern tubes are fitted to provide a bearing for the

tail end shaft and to enable a watertight gland to be fitted at an accessible

position.

The tube is usually constructed of cast steel with a

flange at its forward end and a thread at the after end. It is inserted from

forward and this end is bolted over packing to the after peak bulkhead. A large

nut is placed over the thread at the after end, tightened and secured to the

propeller post.

In an oil lubricated stern

tube the bearings are made of white metal. A gland is fitted to each end of the

stern tube and since the after end gland will not be accessible during sea

service it is made self adjusting. The flange shown is attached to the

propeller so that it rotates with the shaft and oil tightness is obtained by a

rotating gland.

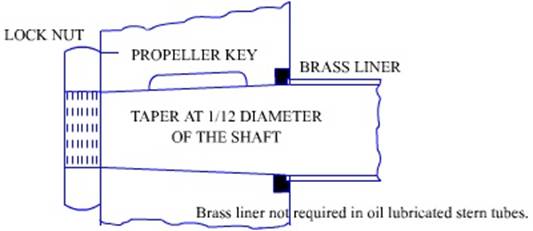

States how

the propeller is attached to the tailshaft

The after end of the tail end shaft is tapered to

receive the propeller boss and a key is provided to transfer the torque from

the shaft to the propeller. A nut fitted with a locking plate secures the

propeller in position and as an additional safeguard it is fitted with a left

hand thread in association with a right hand ed propeller or vice versa.

To remove the propeller and the tail end shaft the

propeller should be slung on special eyes provide on the shell for this purpose

– the rope guards removed – and the propeller nut slackened.

The propeller is then started from the shaft by

driving steel wedges between the boss and the propeller post. When it is free

the nut is removed.

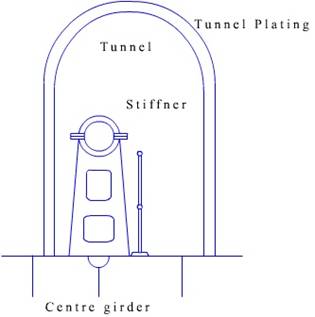

Cross‑section of a shaft tunnel