| Load Lines | Rudder & Propeller |

Ship Construction

Fittings

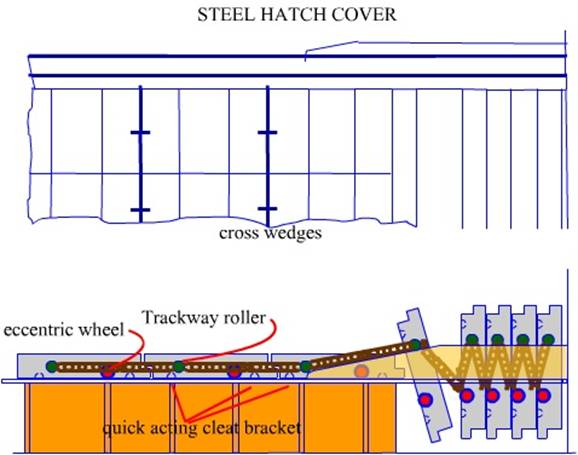

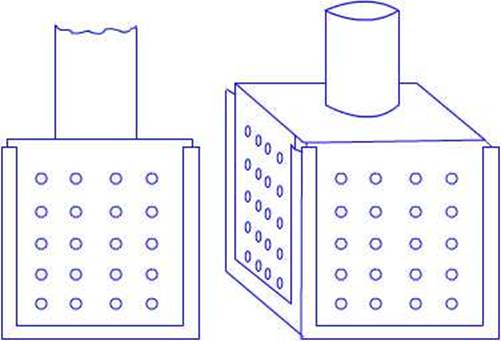

Mechanical Hatch covers

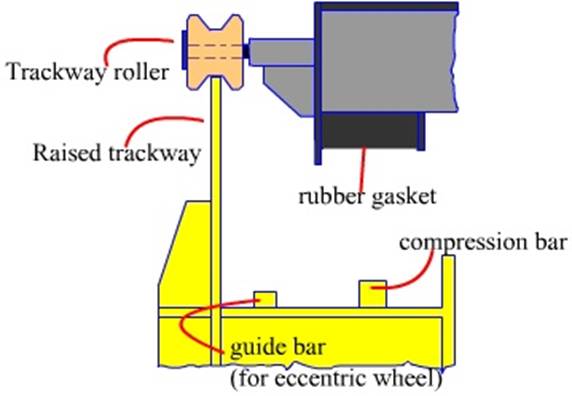

The figures shown below illustrate the various parts

of a mechanical hatch cover. These hatch covers may be made up of several

individual pontoons (so named because prior to the MacGregor

type of rolling hatch covers the pontoons had to be individually lifted and

battened down).

The

pontoons (individual parts of the hatch covers) are connected to one another

and can easily and quickly be rolled into or out of position leaving clear

hatchways and decks. The normal practice for the lengthwise opening of hatches

but sideways opening hatchways are found on large bulk carriers and OBOs.

The smaller versions are mainly

operated either manually (using wire and winch) or electrically. The larger

ones are nearly all operated hydraulically.

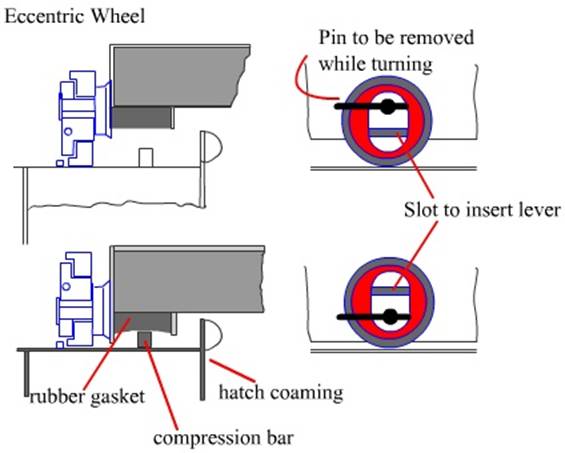

The wheels on the side on which the pontoons rollere

are eccentric in their construction thus when in the battened (lowered)

position the clearance between the wheel and the trackway

is minimum and the pontoon sits on the trackway, the

rubber gaskets being compressed by the compression bar.

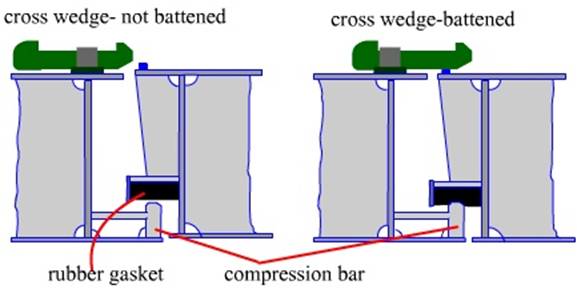

The cross

wedges are used to ensure the pontoon rubber gaskets compress against the

compression bars of the forward pontoons.

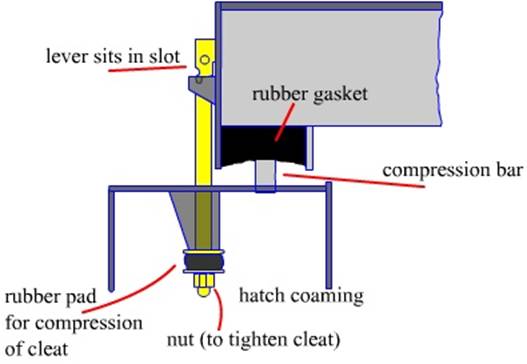

The side

cleats ensure that the pontoons stay compressed to the trackway

compression bar and the ship motion is effectively compensated or removed.

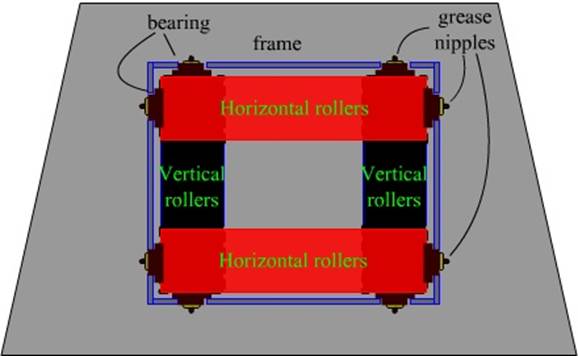

These hatch cover systems consist of various parts:

The pontoons, eccentric wheels, trackway

wheels, cross wedges, and the side cleats.

Battening down a hatch is to be done after reading the

operations manual.

A hatch cover should not be battened with cargo on

top.

The Channels are to be swept prior battening so that

the packing do not rest on dirt.

The drain channel on the front of the hatch pontoons

are to be cleaned prior closing the hatch.

Once the wheels are turned the next item to be engaged

are the cross wedges and the side cleats are to be fitted last.

Prior proceeding to sea (long voyage) the hatch cover

sealing should be tested with chalk marks made on all the compression bars on

the hatch coaming as well as on the pontoons. The hatch is to be battened and

then opened to see if all the rubber gaskets have got chalk mark on them or not

if not hen rectification to be done.

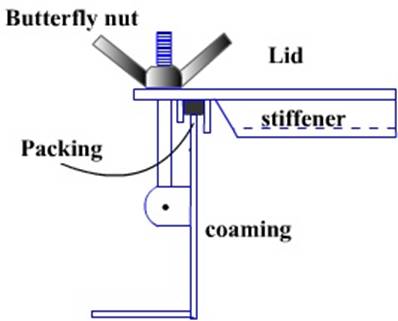

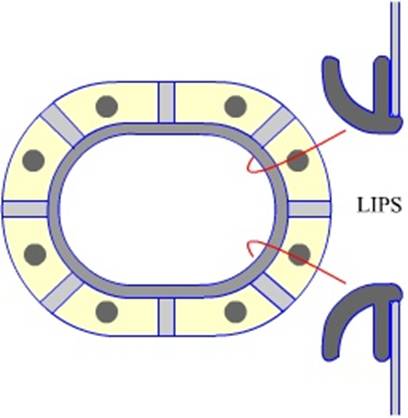

Oil tight hatchcover

These hatch covers are small in size and may have

butterfly nut locking arrangement. The sealing is done by Hi-nitrile rubber

which is not affected by oil.

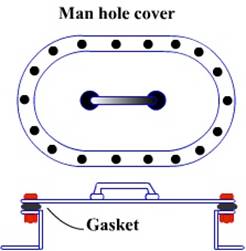

Manhole covers do

not vary much in design, their shape however are sometimes different for

different places.

When fitted outside a tank they may be either circular or elliptical. But when fitted inside they are almost always elliptical to facilitate their removal.

Usual size openings vary between 450mm to about 600mm.

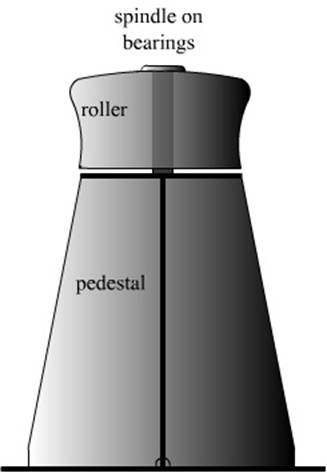

Roller, Multi‑angle, Pedestal and

A roller is to be found on the forward and after

stations area generally at the leads to the mooring ropes as well as on top

of old man pedestals.

These facilitate the hauling of ropes since they

reduce the friction when the rope is hauled through a panama fairlead which has

no rollers.

A panama fairlead

is o named since they were mostly used in the

A multi angle

fairlead again is a fairlead used due necessity when in the great Lakes. The

ship moves through numerous locks as the ship is made to climb a great height

the

Mooring

bitts are prefabricated and then are welded onto the deck. The size of the bitts are dependent on their use. Thus a small

set may be fitted next to an occasional winch while the larger ones are fitted

at the mooring stations.

The bitts are hollow and as such require care to

ensure that the sides do not corroded and holed.

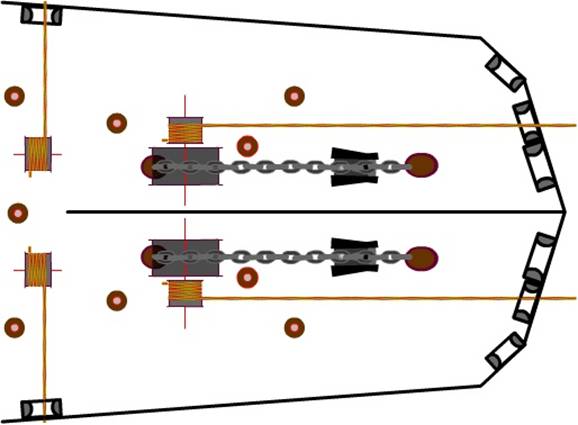

A typical

forecastle mooring and anchoring arrangement, showing the leads of moorings

Securing

anchors and making spurling pipes watertight in preparation for a sea passage

Once the anchor has been washed the anchor is hove

right up into the hawse pipe, the bow stopper is lowered and the locking pin

inserted.

The winch is reversed a little to make the chain sit

properly into the slot of the bow stopper and then the brake is tightened and

the windlass gear removed.

The anchor chain at the deck level (hawse pipe) is

lashed with extra lashings as provided by the shipyard, if none are present or

if expecting heavy weather, then extra wire rope lashings are taken, The wire

rope to be used should be tested one, if an old (good condition) life boat

falls are available then this makes a very good extra lashing wire. This wire

is flexible and can be used by hand. A number of turns (figure of eight) are

taken around two sets of bitts. The free ends being fastened by bull dog clips

at least two fixed in opposite directions.

Generally the shipyard would have provide

lashing point as well as short length of wire attached to a bottle screw. These

should be well oiled and are the most efficient for lashing the anchor. The

wire should be tight.

Once the anchor is lashed the hawse pipe covers are

not placed but stowed under deck or in their stowage positions.

The spurling pipe area is chipped to remove any

residual remains of earlier cement.

The metal spurling pipe covers are placed around the

chain and over the spurling pile. The clips provided at the edges of the covers

should be hooked to the lips of the spurling pipe.

A new canvas cover is then placed over the metal

covers just fitted and is tied around the lips of the spurling pipe as well as

the chain. No empty spaces should be found.

Cement mixture is prepared and the entire cover is

covered with this mixture.

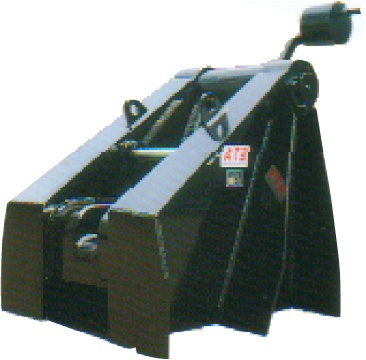

Cable stopper

A chain stopper as shown below may be of various

designs, but all serve the same purpose to hold the cable.

The cable is passed through the stopper with the

holding bar lifted up by the counterweight on top. There is a pin to hold the

bar in this

position.

Once the decision has been taken to hold the cable,

the safety locking pin is removed and the bar is eased down on top of the

cable. Note that the default position of the holding bar is to arrest the

cable, only a effort is required to keep it up.

Once the bar is placed over the cable the cable may

have to be adjusted a little to ensure that the flat part of the cable falls in

the holding area and not the vertical section, the safety locking pin is now

introduced to prevent the bar from jumping u[ in case the cable slip from the

brake.

Once the lacking pin is in position the brake can be

released and the stopper would do the work of holding the cable.

Masts and

Sampson posts

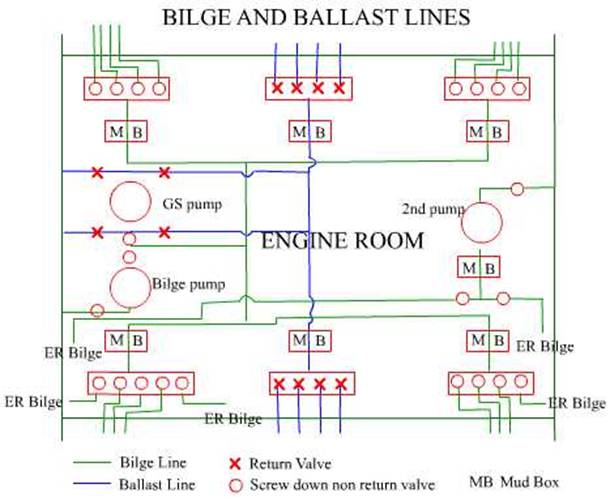

Bilge and ballast piping system of a cargo ship

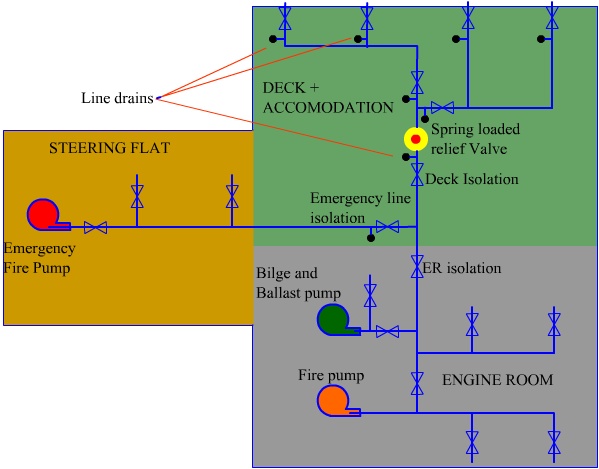

The following shows a bilge and ballast line diagram

of a general cargo ship.

The bilges are all fitted with non return valves so

that not water may be inadvertently be pumped into the holds.

The bilges are serviced by a bilge pump which

incorporates a strainer and this should be checked before starting the pump.

The strum box fitted in the holds is to be kept clean

and the perforations are to be checked that they are not closed due to muck and

rust.

Same with the mud boxes in the ER fitted into the

system.

Arrangement of a fire main

Capacity of

fire pumps

The capacity of the fire pumps is stated in SOLAS but

need not exceed 25m3 per hour

Arrangements of fire pumps and of fire mains

Ships shall be provided with independently driven fire

pumps as follows:

Passenger ships of 4,000 tons gross tonnage and

upwards at least three

Passenger ships of less than 4,000 gross tonnage and

cargo ships of 1,000 tons gross tonnage and upwards at least two

Cargo ships of less than 1,000 tons gross tonnage to

the satisfaction of the Administration

Sanitary, ballast, bilge or general service pumps may

be accepted as fire pumps, provided that they are not normally used for pumping

oil and that if they are subject to occasional duty for the transfer or pumping

of oil fuel, suitable change-over arrangements are fitted.

The arrangement of sea connections, fire pumps and

their sources of power shall be such as to ensure that:

In passenger ships of 1,000 gross tonnage and upwards,

in the event of a fire in any one compartment all the fire pumps will not be

put out of action.

In cargo ships of 2,000 gross tonnage and upwards, if

a fire in any one compartment could put all the pumps out of action there shall

be an alternative means consisting of a fixed independently driven emergency

pump which shall be capable of supplying two jets of water to the satisfaction

of the Administration. The pump and its location shall comply with the

following requirements:

The capacity of the pump shall not be less than 40% of

the total capacity of the fire pumps required by this regulation and in any case not less than 25 m3/h.

Number and position of hydrants

The number and position of hydrants shall be such that

at least two jets of water not emanating from the same hydrant, one of which

shall be from a single length of hose, may reach any part of the ship normally

accessible to the passengers or crew while the ship is being navigated and any

part of any cargo space when empty, any ro-ro cargo space or any special

category space in which latter case the two jets shall reach any part of such

space, each from a single length of hose. Furthermore, such hydrants shall be

positioned near the accesses to the protected spaces.

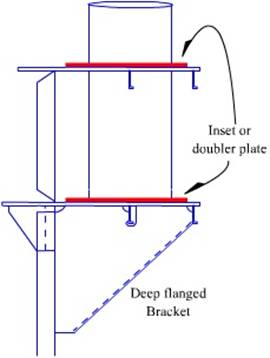

Pipes and hydrants

Mainly galvanised steel pipes are used and during

repairs no doublers or such part renewals are allowed change is flange to

flange renewal.

The arrangement of pipes and hydrants are to be such

as to avoid the possibility of freezing.

On cargo ships where deck cargo may be carried, the

positions of the hydrants are to be such that they are always readily

accessible and the pipes are to be arranged, as far as practicable, to avoid

risk of damage by such cargo.

A valve is to be fitted at each fire hydrant so that

any fire-hose may be removed while the fire pump is at work.

The above figure shows a typical fire mains line. Note

that the emergency fire pump is located away from the machinery space as per

rules.

Isolation valves are provided so that any system being

damaged the other system may be used for example the port system and the starboard

system.

In the machinery space a separate pump (Fire and GS

pump) is also coupled, this is generally used when washing decks, and as an

emergency measure while the fire pump is being overhauled.

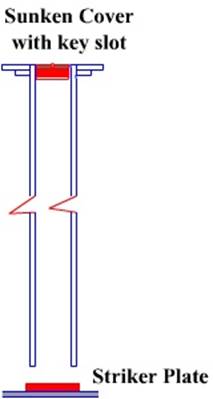

Sounding pipes

Sounding pipes covers come with varied designs. That

shown below is a sunken cap type generally the cap is made of brass. The

justification being that of the two thread and cap

assembly the thread of the brass is to wear out first and that of the deck pad.

The renewal of the brass cap being inexpensive and convenient

rather than the deck pad which entails hot work.

The metal cap (not sunken) type of

covers have a chain attached to them to prevent their being washed

overboard.

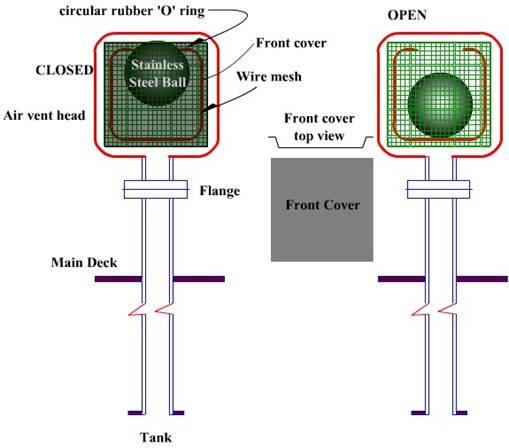

Air pipes to ballast tanks or fuel oil tanks

The above figure shows a design of air pipe cover.

In normal condition the ball remains at the bottom

of the air pipe head and the tank breathes in and out through the vent.

However in the event that the air pipe is submerged

then the ball floats up and closes the opening at the top thus preventing any

water from entering the tank.

Sea spray and rain is prevented from entering the tank

by the design of the head. It is totally enclosed and a rectangular plate,

which leaves a small gap between the mesh and itself, allowing the breathing of

the tank.

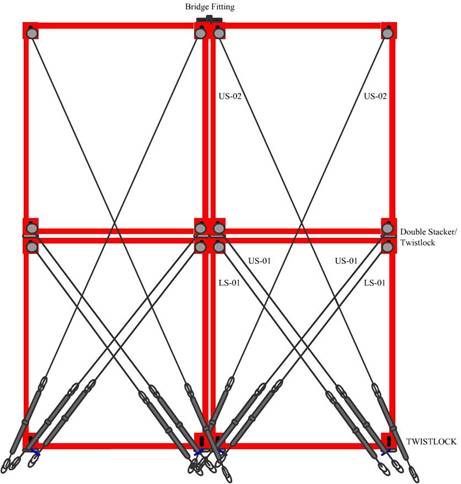

Fittings

and lashings for the carriage of containers on deck

In the figure above the containers on deck are loaded on top of shoes

which are welded on top of the deck as well on top of the hatch covers.

Twistlocks are fitted

on the shoes and the containers placed on the twistlocks.

Hinged eyes are welded on deck to secure the container rod lashings.