| Load Lines | Rudder & Propeller |

Ship Construction

Bow and Stern

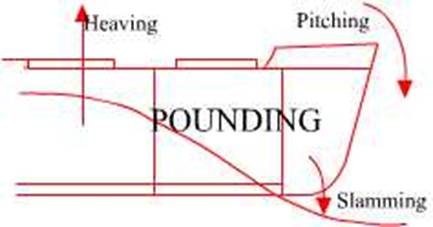

Pounding

and the additional provisions to withstand such pounding:

Heavy pitching assisted by heaving as the

whole vessel is lifted in a seaway may subject the forepart to severe blows

from the sea. The greatest effect is experienced in the light ship condition.

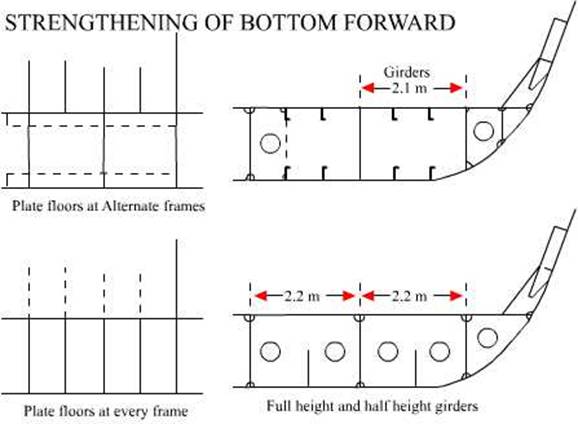

To compensate for this the bottom is strengthened from 0.5L to between 0.25L

and 0.3L from forward depending on the block coefficient, unless the ballast

draught forward is over 0.04L.

Bottom

framed Longitudinally

Longitudinals are to be spaced 1000mm

apart between 0.2L and 0.3L from forward and 700mm apart between 0.2L from

forward and the collision bulkhead. Plate floors are to be fitted alternate

frames, side girders not more than 2.1m apart.

Bottom

framed Transversely

Frame spacing abaft 0.2L from forward is

not to exceed 1000mm and between 0.2L and the collision bulkhead 700mm. Forward of the collision bulkhead 610mm. Plate floors are to

be fitted at every frame. Intercostal side girders are to be not more than 2.2m

apart with half height side girders not more than 1.1m apart, the girders

extending as far as is practicable.

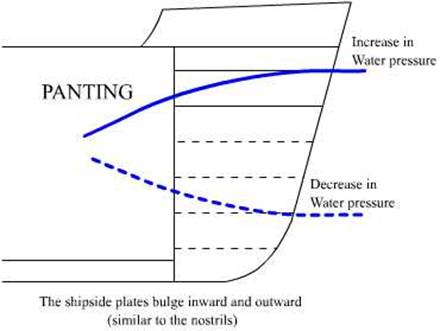

Panting

This is a stress, which occurs at the ends

of a vessel due to variations in water pressure on the shell plating as the

vessel pitches in a seaway. The effect is accentuated at the bow when making

headway.

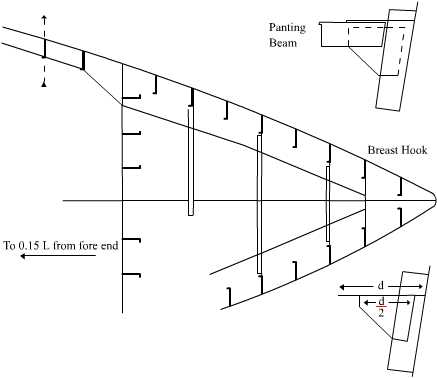

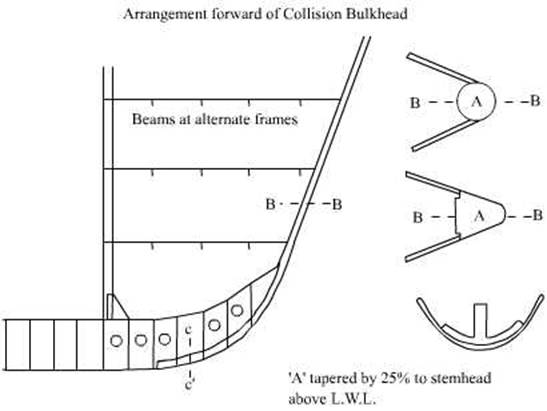

Panting arrangements are to extend 0.15L

from forward and abaft the after peak bulkhead.

Tiers of beams spaced not more than 2000mm

apart vertically are to be fitted at alternate frames in the fore peak or below

the lower deck above the water line if the forepeak is small. Alternatively

perforated flats may be fitted in lieu of panting beams 2.5m apart vertically.

Tiers of beams are to be supported at the

centreline by a partial wash bulkhead or pillars. Beams are to be bracketed to

frames and the frames to which no beams are attached are to be bracketed to the

stringer. Stringer plates attached to the shell are to be fitted at each tier

of beams.

Abaft the collision bulkhead intercostals

side stringers having the same depth as the frames are to be fitted in line

with those forward of the collision bulkhead and are to extend aft for 0.15L

from the fore end. Stringers may be omitted if the shell plating is of

increased thickness.

Abaft the after peak bulkhead the

structure is to be efficiently stiffened by deep floors and tiers of beams in

association with stringers spaced 2500mm apart vertically.

Stern

Frame

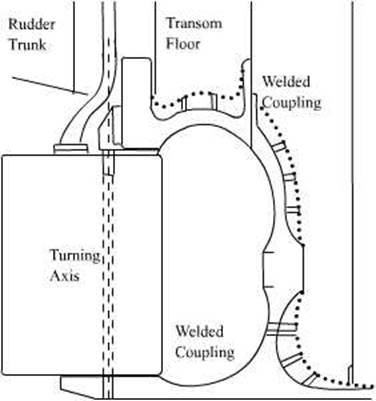

Stern frames may be cast/ forged or

fabricated from steel plate. In the case of cast or forged steel frames they

may be in one piece or in two or more sections riveted or welded together (thermit welding).

Where a riveted connection is used the two

sections of the bar are scarphed together and the

class rules for the scarph are 3D and the depth as

one and one third D, where D is the depth of the bar used in the construction

of the frame.

A scarph fitted

in a rudder post should not be above the highest gudgeon.

Cast steel and fabricated stern frames are

to be strengthened at intervals by transverse webs. All stern frames are to be

efficiently attached to the adjoining structure and the lower part of the stern

frame is to be extended forward to provide an efficient connection to the flat

plate keel.

With larger stern frames there is a

tendency for the whole stern or propeller post and adjacent sections to be

fabricated.