| Load Lines | Rudder & Propeller |

Ship Construction

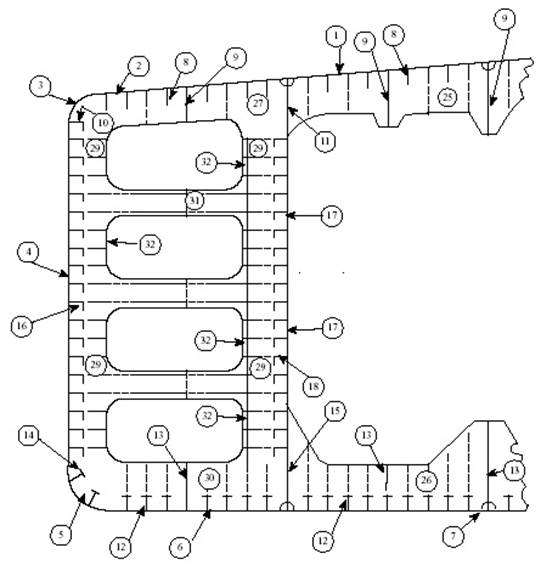

Structural components on ships’ plans and drawings:

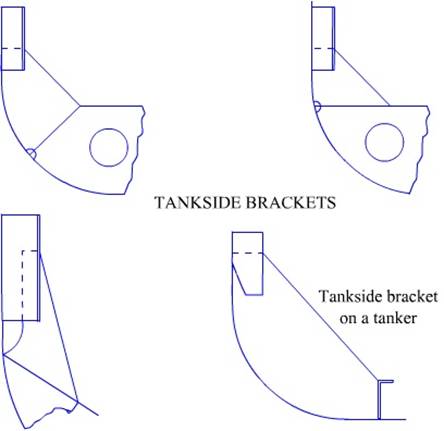

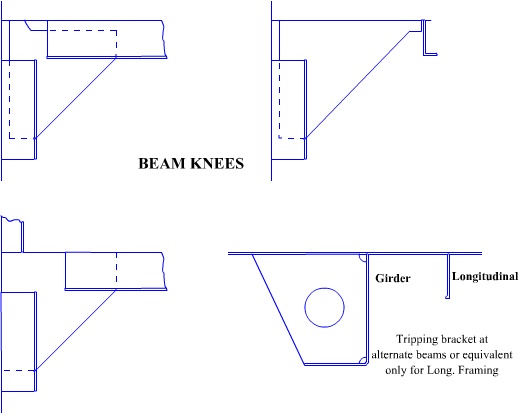

frames, floors, transverse frames, deck beams, knees, brackets, shell plating,

decks, tank top, stringers, bulkheads and stiffeners, pillars, hatch girders

and beams, coamings, bulwarks

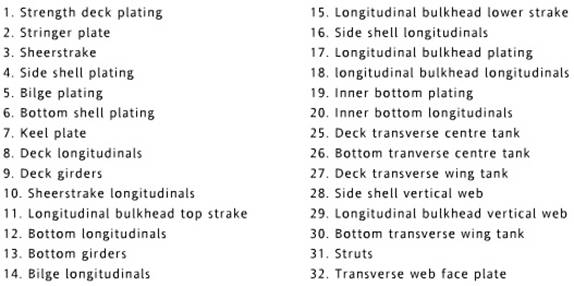

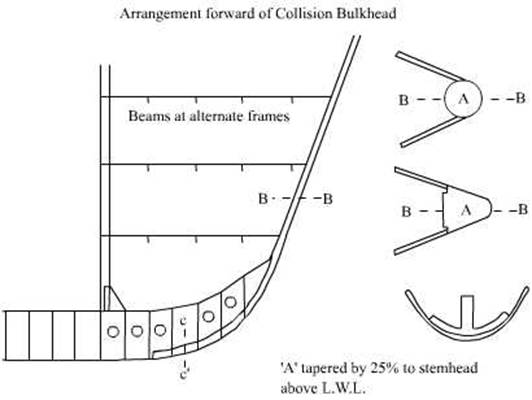

Bow and stern framing, cant beams, breasthooks

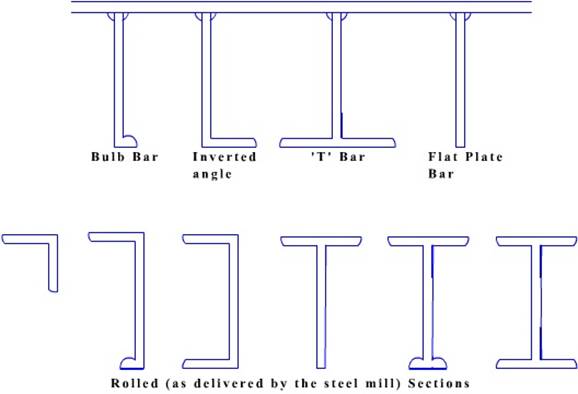

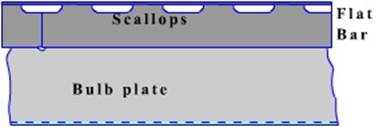

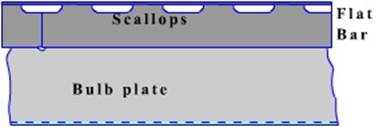

Description

of standard steel sections: flat plate, offset bulb plate, equal angle, unequal

angle, channel, and tee

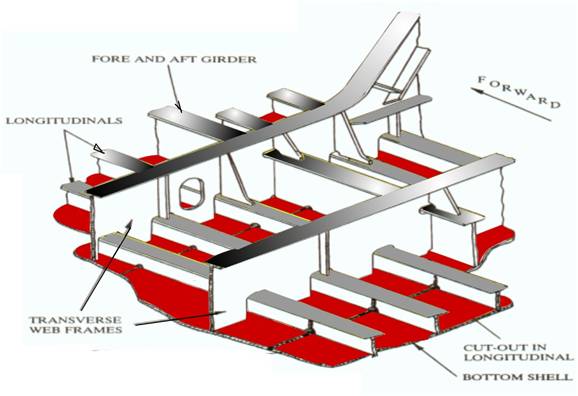

Longitudinal,

transverse and combined systems of framing on transverse sections of the ships

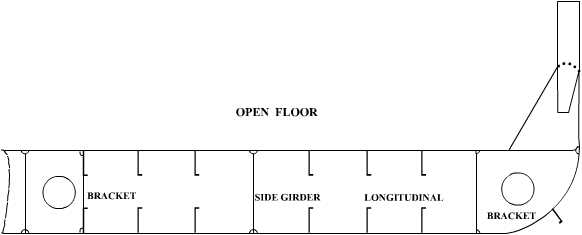

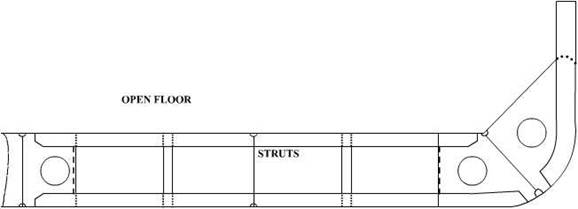

Longitudinal framing – Open floors

Longitudinal

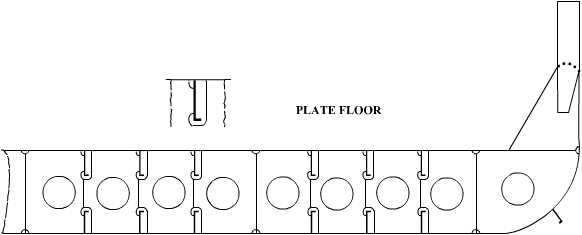

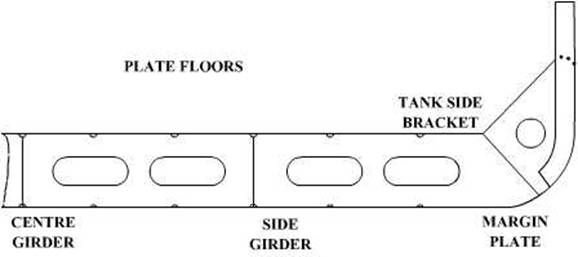

framing – Plate floors

Transverse framing – Open floors

Transverse framing – Plate floors

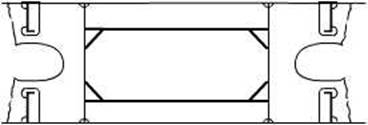

Duct keel

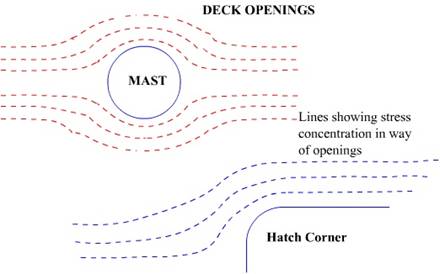

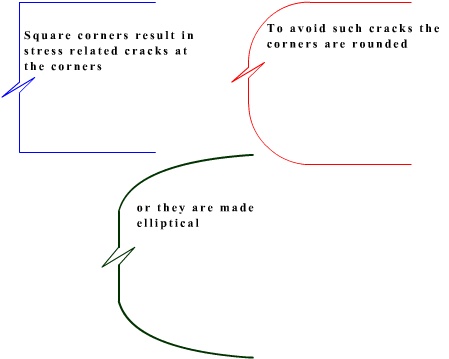

Stress

concentration in the deck round hatch openings

Holes cut in the deck plating by way of hatchways,

masts and others create areas of high local stress due to lack of continuity

created by the opening.

Compensation for loss of strength at hatch openings

Compensation around some of these openings may be overcome

by increasing the sizes of the material used, buy a careful disposition of the

material and by paying careful attention to the structural design.

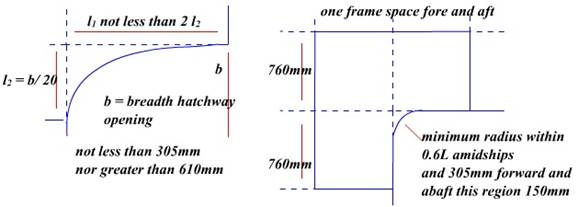

Compensating for the stress concentration around hatch

corners by rounding off the square hatch corner ends

The corners radiused to reduce the stress

concentration

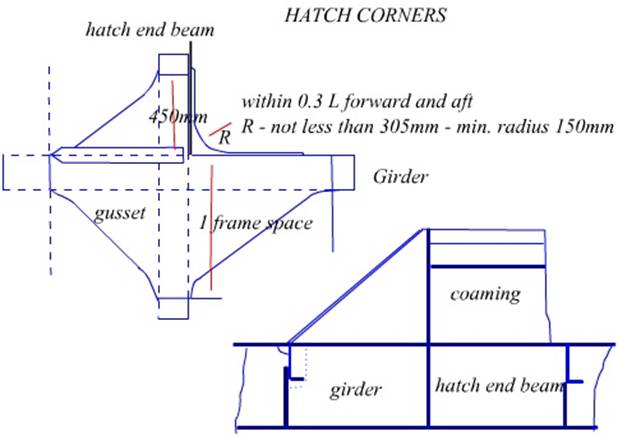

A hatch corner in plan view, showing the structural

arrangements

A transverse section through a hatch coaming, showing

the arrangement of coamings and deep webs

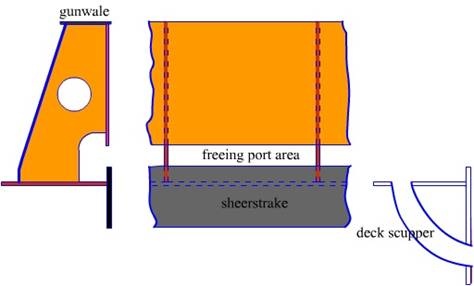

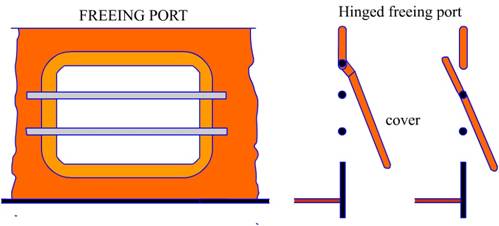

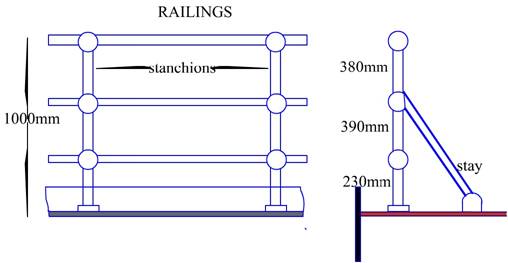

Deck‑freeing

arrangements - scuppers, freeing ports, and open rails

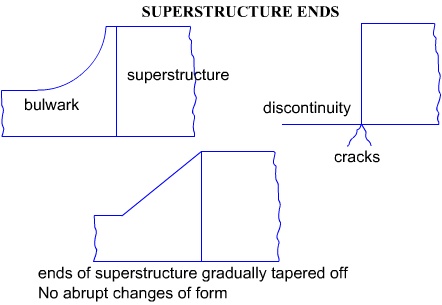

Connection of superstructures to the hull at the ship’s side

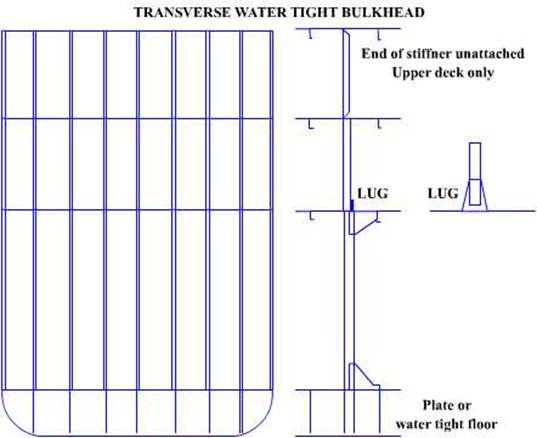

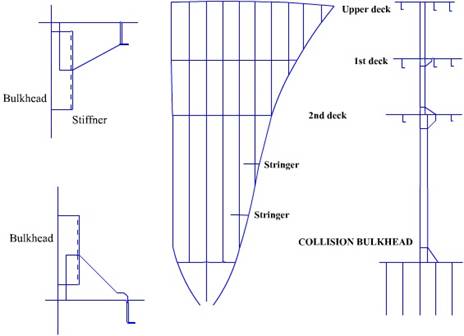

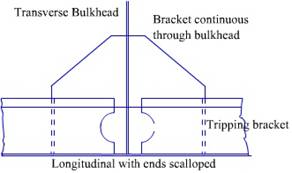

A plane bulkhead, showing connections to deck, sides and double bottom and the arrangement of stiffeners

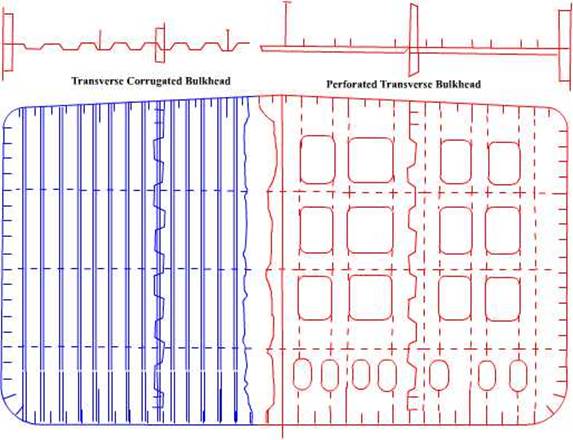

A corrugated bulkhead

Transverse

bulkheads have vertical corrugations and fore and aft bulkheads have horizontal

ones

The basic idea of a bulkhead in addition

to the water tight integrity is to add to the girder strength of the ship beam.

Thus for a transverse bulkhead, which

extends from the port to the starboard side or vice versa, the framing is done

in a vertical manner so that the compressive and the tensile stress may be

reduced for the beam.

Similarly for a longitudinal bulkhead

which runs parallel to the shipside the framing is done vertically, again so

that the additional strength would enhance the stress compensating effect of

the ship beam.

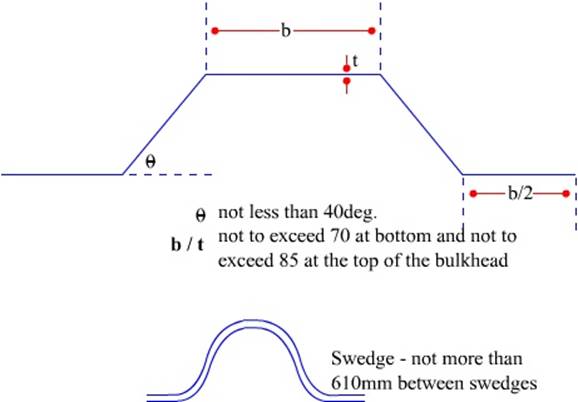

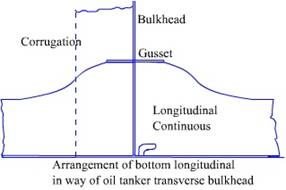

Construction

of the corrugated bulkhead

A fitted corrugated bulkhead

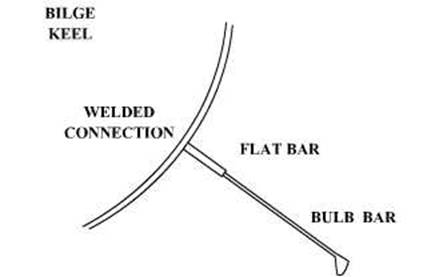

Purpose of

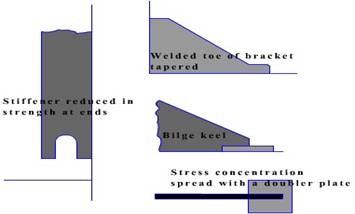

bilge keels and their attachment to the ship’s side

Bilge keels are fitted at the turn of the bilge to resist rolling. They also improve the steering qualities of the ship – though very slightly.

The ends are to be gradually tapered and should not

end on an un-stiffened panel.

Stress relieving while fitting the bilge keel

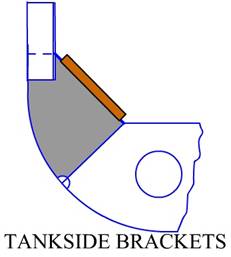

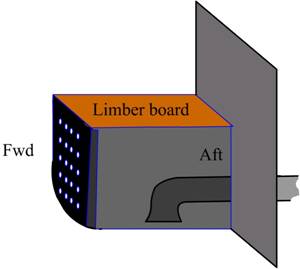

Hold drainage systems

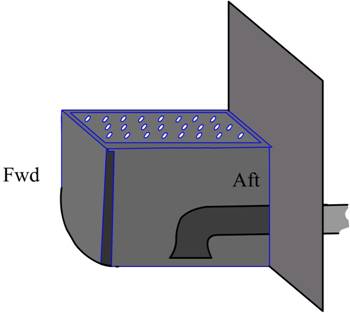

The hold drainage system of older cargo vessels had limber board covered upper side of the tank side bracket areas. The drainage conduit was these areas and the pipelines were connected to the after ends, which passed through the lightening holes in the DB’s.

The limber boards were removable for cleaning as they

were frequently damaged (edges) leaving gaps through which cargo residue would

accumulate.

Modern ships do not have the side bilges and have only

a strum box at the after end of the holds and these are connected in the

similar way to pipelines, which run through the DB’s.