| Grain Cargo | Cargo Care | IMDG | Cargo Handling Equipment | Cargo Handling Safety | |

| Oil Tanker | Cargo Measurement | Enclosed Spaces |

Cargo Work

Deck Cargo

Cargo which are normally carried on deck include the following but are not limited to these and many exceptional cargoes may be carried and also have been carried in the past.

Dangerous cargo – IMDG cargo not permitted on deck

Large packages which due to any size restriction may

have to be loaded on to the deck

The above includes engineering or construction

equipment

Odd size package

Where the bulk volume far exceeds the weight of the

cargo – knocked down bridges, port equipment – not easily liable to weather

damage.

Occasionally livestock in limited numbers

Onions or other perishables – short voyages with the

weather holding

Yachts – luxury boats.

Cast iron goods – man hole covers – pipes.

The list is endless and it all depends on the routes,

the trading pattern and the weather.

The cargo whether on deck or under deck stow has to be

stowed well and the cargo should be prevented from moving and gaining enough

momentum to part lashings and damage the ship structure.

Deck cargo is liable to damage itself – fall overboard

and thus be lost. However the misery does not stop here in the act of parting

lashing and going overboard the deck cargo unleashes considerable damage to the

ship structure as well as the crewmembers.

Small apparently insignificant items such as sounding

pipes and air pipes are often torn out and this may endanger the ship from the

resulting chances of flooding lower down compartments.

Crewmembers ordered to lash cargo where the lashings

have parted have been seriously injured and some have lost lives combating the

shifting cargo.

The point is to have a good solid stow – prevent the

cargo from shifting and gaining momentum with the shift. Since this would part

any strong lashing. The lashing undertaken should be for the worst sea

condition that may be experienced.

Deck cargo loading on top of hatch covers should be

carefully planned. All loading of under deck spaces should have been completed

– lashing may continue with portable lights.

The hatch covers should be closed and battened down –

all side wedges as well as cross wedges (centre wedges) should have been

fitted. With the hatch cover sealed for sea, the space should then be given out

for loading of deck cargo.

The permissible load density of the hatch covers

should be checked and timbers laid to spread the weight of the cargo. The load

density of the hatch covers are given for a new vessel and as the ship ages the

load density would reduce due to fatigue of the metal as well as wear and tear.

Thus the utmost need to spread the weight using timber.

Shoring and toming of the hatch cover from below deck

is practically useless since the hatch cover moves/ slides somewhat with the

motion of the ship.

The height of the cargo on the hatch covers as well as

that on deck should not be so high that the view is obstructed from the

Ice accumulation on hatch cover and on deck

The above photographs show the extent of the weight that Ice accumulation can pose for a ship. The weight on deck may eventually lead a ship to progress to a condition of ‘angle of loll’.

The weight of the ice may be in excess of a hundred

tonnes, and thus the danger of a ship regarding stability.

As with the above any deck cargo for that matter would

have a very high KG as such the GM (F) would be quite small. Especially in the

case of GC vessels, which do not have a very large GM (F) the loading of deck

cargo, is bound to lead to further loss of GM (F). If the ship loads the deck

cargo with her own gear then the ship would during the loading operation have

still further low GM (F) due to the KG of the load being at the top of the

derrick/ crane for part of the loading sequence.

Containers on deck

Containers when they are loaded on deck are subject to

the following consideration – barring stability, which would have been planned

for.

The load density of the deck

Spreading the load of the container evenly

Chocking the container base to prevent shifting due to

rolling or pitching

Lashing the container for the above as well to prevent

the container from being bodily lifted.

Placing the containers in as close a group as possible

Safeguarding the sounding pipes and the air pipes

within the periphery of the container space.

Keeping the fire hose boxes clear as well as the

passage leading to them, the fire hydrants should similarly be kept clear.

No lashing should be taken which would damage or cause

to be damaged the fire lines.

Checking that the leads for the lashing wires are

adequate as well as that the chocking points are well supported

Keeping a passage for crew members to check the

lashings during g voyage.

In general the close stow is difficult on GC vessels

where the container is usually loaded between the hatch coaming and the

bulwark. So the container should be loaded as close as possible to the hatch

coaming, as well as close to the Mast House structure. If few containers are

being loaded then the shelter offered by the Mast House structure should be

kept in mind.

The load is spread by having the container loaded onto

timbers at least 4” x 4”. The timbers should be extended to well beyond the

shoe of the container in all directions to spread the load. Once this is done

the chocking of the container is started. Again heavy timbers are used and the

container is first secured to prevent any lateral and transverse shifting.

While selecting chocking points all heavy framework should be selected. Bulwark

stays are not strengthened enough to be used as chocking points. Hatch coamings

may be used and as a last resort bulwark stays. After the chocking is completed

the container is lashed. The lashing is further to prevent the longitudinal as

well as the transverse shifting. For this the base shoes offer the best lashing

points. To prevent the container being bodily shifted out the lashings are continued

to the top shoes.

All lashing should be separate in the sense that a

single lashing wire should not be passed over a few shoes and then lashed at

the final point. Each lashing should have a turnbuckle or bottle screw

incorporated and there should be at least 60% free thread in them after

completion of lashing.

The bottom lashing and the top lashing should not be

counted together fore the purpose of assessing the total number of lashings

taken for the container.

The top lashings are for bodily rise and as such

should be counted separately.

As a thumb rule, if the SWL of the lashing wire is 2T

then to lash the top of a 20T container the number of lashings should be a

minimum of 10 (all well positioned), similarly the bottom should have 10. The

bottom lashings may be reduced depending upon the chocking of the container and

the availability of the lashing point.

Note that a single strong point for lashing should not

have more than 2 lashing wires – the preferred would be 1, however it is often

impossible to find so many lashing points.

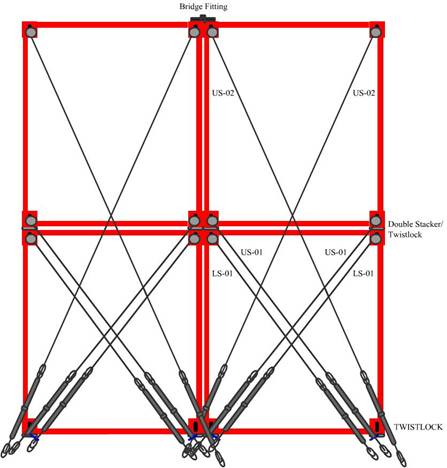

This shows a container ship lashing; note that the

container is loaded onto the ship shoe slots which are strengthened, the rod

lashings are only for the top of the containers.

Here the bottom shoes are not lashed since the ships

sunken shoes and twist locks effectively chock and lash the bottom of the

container.

Stowage and

Lashing of Timber deck cargoes as laid down by IMO code of Safe Practice for

Ships Carrying Timber Deck Cargoes

Purpose

The purpose of the Code is to make recommendations on

stowage, securing and other operational safety measures designed to ensure the

safe transport of mainly timber deck cargoes.

Application

This Code applies to all ships of 24 m or more in

length engaged in the carriage of timber deck cargoes. Ships that are provided

with and making use of their timber load line should also comply with the

requirements of the applicable regulations of the Load Line Convention.

Timber means sawn wood or lumber, cants, logs, poles,

pulpwood and all other type of timber in loose or packaged forms. The term does

not include wood pulp or similar cargo.

Timber deck cargo means a cargo of timber carried on

an uncovered part of a freeboard or superstructure deck. The term does not

include wood pulp or similar cargo.

Timber load

line means a special load line assigned to ships complying with

certain conditions related to their construction set out in the International

Convention on Load Lines and used when the cargo complies with the stowage and

securing conditions of this Code.

Weather deck means the uppermost complete deck exposed

to weather and sea.

The

stability of the ship at all times, including during the process of loading

and unloading timber deck cargo, should be positive and to a standard

acceptable to the Administration. It should be calculated having regard to:

The increased weight of the timber deck cargo due to:

Absorption of water in dried or seasoned timber, and

Ice accretion, if applicable;

Variations in consumables;

The free surface effect of liquid in tanks; and

Weight of water trapped in broken spaces within the

timber deck cargo and especially logs.

Safety precautions to be taken as far as stability of

the ship is concerned

The master should:

Cease all loading operations if a list develops for which

there is no satisfactory explanation and it would be imprudent to continue

loading;

Before proceeding to sea, ensure that:

The ship is upright;

The ship has an adequate metacentric height; and

The ship meets the required stability criteria.

Ships carrying timber deck cargoes should operate, as

far as possible, with a safe margin of stability and with a metacentric height

which is consistent with safety requirements but such metacentric height should

not be allowed to fall below the recommended minimum.

However, excessive initial stability should be avoided

as it will result in rapid and violent motion in heavy seas which will impose

large sliding and racking forces on the cargo causing high stresses on the

lashings. Operational experience indicates that metacentric height should

preferably not exceed 3% of the breadth in order to prevent excessive

accelerations in rolling provided that the relevant stability criteria are

satisfied.

This recommendation may not apply to all ships and the

master should take into consideration the stability information obtained from

the ship’s stability manual.

STOWAGE

General

Before timber deck cargo is loaded on any area of the

weather deck:

Hatch covers and other openings to spaces below that

area should be securely closed and battened down;

Air pipes and ventilators should be efficiently

protected and check valves or similar devices should be examined to ascertain

their effectiveness against the entry of water;

Accumulations of ice and snow on such area should be

removed; and

It is normally preferable to have all deck lashings,

uprights, etc., in position before loading on that specific area. This will be

necessary should a preloading examination of securing equipment be required in

the loading port.

The timber deck cargo should be so stowed that:

Safe and satisfactory access to the crew’s quarters,

pilot boarding access, machinery spaces and all other areas regularly used in

the necessary working of the ship is provided at all times;

Where relevant, openings that give access to the areas

can be properly closed and secured against the entry of water;

Safety equipment, devices for remote operation of

valves and sounding pipes are left accessible; and

It is compact and will not interfere in any way with

the navigation and necessary working of the ship.

During loading, the timber deck cargo should be kept

free of any accumulations of ice and snow.

Upon completion of loading, and before sailing, a

thorough inspection of the ship should be carried out. Soundings should also be

taken to verify that no structural damage has occurred causing an ingress of

water.

On ships provided with, and making use of, their

timber load line, the timber deck cargo should be stowed so as to extend:

.1 over the entire available length of the well or

wells between superstructures and as close as practicable to end bulkheads;

.2 at least to the after end of the aftermost hatchway

in the case where there is no limiting superstructure at the aft end;

.3 athwartships as close as possible to the ship sides,

after making due allowance for obstructions such as guard rails, bulwark stays,

uprights, pilot boarding access, etc., provided any area of broken stowage thus

created at the side of the ship does not exceed a mean of 4% of the breadth;

and

.4 to at least the standard height of a superstructure

other than a raised quarterdeck.

The basic principle for the safe carriage of any

timber deck cargo is a solid stowage during all stages of the deck loading.

This can only be achieved by constant supervision by shipboard personnel during

the loading process.

SECURING

General

Every lashing should pass over the timber deck cargo

and be shackled to eye plates and adequate for the intended purpose and

efficiently attached to the deck stringer plate or other strengthened points.

They should be installed in such a manner as to be, as far as practicable, in

contact with the timber deck cargo throughout its full height.

All lashings and components used for securing should:

.1 possess a breaking strength of not less than 133

kN;

.2 after initial stressing, show an elongation of not

more than 5% at 80% of their breaking strength; and

.3 show no permanent deformation after having been

subjected to a proof load of not less than 40% of their original breaking

strength.

Every lashing should be provided with a tightening

device or system so placed that it can safely and efficiently operate when

required. The load to be produced by the tightening device or system should not

be less than:

.1 27 kN in the horizontal part; and

.2 16 kN in the vertical part.

NOTE: 1

Upon completion and after the initial securing, the

tightening device or system should be left with not less than half the threaded

length of screw or of tightening capacity available for future use.

Every lashing should be provided with a device or an

installation to permit the length of the lashing to be adjusted.

The spacing of the lashings should be such that the

two lashings at each end of each length of continuous deck stow are positioned

as close as practicable to the extreme end of the timber deck cargo.

If wire rope clips are used to make a joint in a wire

lashing, the following conditions should be observed to avoid a significant

reduction in strength:

.1 the number and size of rope clips utilized should

be in proportion to the diameter of the wire rope and should not be less than

four, each spaced at intervals of not less than 15 cm;

.2 the saddle portion of the clip should be applied to

the live load segment and the U-bolt to the dead or shortened end segment;

.3 rope clips should be initially tightened so that

they visibly penetrate into the wire rope and subsequently be retightened after

the lashing has been stressed.

Greasing the threads of grips, clips, shackles and

turnbuckles increases their holding capacity and prevents corrosion.

Uprights

Uprights should be fitted when required by the nature,

height or character of the timber deck cargo.

When uprights are fitted, they should:

.1 be made of steel or other suitable material of

adequate strength, taking into account the breadth of the deck cargo;

.2 be spaced at intervals not exceeding 3 m;

.3 be fixed to the deck by angles, metal sockets or

equally sufficient means; and

.4 if deemed necessary, be further secured by a metal

bracket to a strengthened point, i.e., bulwark, hatch coaming.

Loose or packaged sawn timber

The timber deck cargo should be secured throughout its

length by independent lashings.

The maximum spacing of the lashings should be

determined by the maximum height of the timber deck cargo in the vicinity of

the lashings:

.1 for a height of 4 m and below, the spacing should

be 3 m;

.2 for heights of above 4 m, the spacing should be 1.5

m.

The packages stowed at the upper outboard edge of the

stow should be secured by at least two lashings each.

When the outboard stow of the timber deck cargo is in

lengths of less than 3.6 m, the spacing of the lashings should be reduced as

necessary or other suitable provisions made to suit the length of timber.

Rounded angle pieces of suitable material and design

should be used along the upper outboard edge of the stow to bear the stress and

permit free reeving of the lashings.

Logs, poles, cants or similar cargo

The timber deck cargo should be secured throughout its

length by independent lashings spaced not more than 3 m apart.

If the timber deck cargo is stowed over the hatches

and higher, it should, in addition be further secured by:

.1 a system of athwarthship lashings (hog lashings)

joining each port and starboard pair of uprights near the top of the stow and

at other appropriate levels as appropriate for the height of the stow; and

.2 a lashing system to tighten the stow whereby a dual

continuous wire rope (wiggle wire) is passed from side to side over the cargo

and held continuously through a series of snatch blocks or other suitable

device, held in place by foot wires.

The dual continuous wire rope should be led to a winch

or other tensioning device to facilitate further tightening.

Testing, examination and certification

All lashings and components used for the securing of

the timber deck cargo should be tested, marked and certified according to

national regulations or an appropriate standard of an internationally

recognized standards institute. Copies of the appropriate certificate should be

kept on board.

No treatments, which could hide defects or reduce

mechanical properties or strength, should be applied after testing.

A visual examination of lashings and components should

be made at intervals not exceeding 12 months.

A visual examination of all securing points on the

ship, including those on the uprights, if fitted, should be performed before

loading the timber deck cargo. Any damage should be satisfactorily repaired.

Lashing plans

One or more lashing plans complying with the

recommendations of this Code should be provided and maintained on board a ship

carrying timber deck cargo.

Personnel

Protection And Safety Devices

During the course of the voyage, if there is no

convenient passage for the crew on or below the deck of the ship giving safe

means of access from the accommodation to all parts used in the necessary

working of the ship, guard lines or rails, not more than 330 mm apart

vertically, should be provided on each side of the deck cargo to a height of at

least 1 m above the cargo. In addition, a lifeline, preferably wire rope, set

up taut with a tightening device should be provided as near as practicable to

the centreline of the ship. The stanchion supports to all guard rails or

lifelines should be spaced so as to prevent undue sagging. Where the cargo is

uneven, a safe walking surface of not less than 600 mm in width should be

fitted over the cargo and effectively secured beneath, or adjacent to, the

lifeline.

Where uprights are not fitted, a walkway of

substantial construction should be provided having an even walking surface and

consisting of two fore and aft sets of guard lines or rails about 1 m apart,

each having a minimum of three courses of guard lines or rails to a height of

not less than 1 m above the walking surface. Such guard lines or rails should

be supported by rigid stanchions spaced not more than 3 m apart and lines

should be set up taut by tightening device.

As an alternative a lifeline, preferably wire rope may

be erected above the timber deck cargo such that a crewmember equipped with a

fall protection system can hook onto and work about the timber deck cargo. The

lifeline should be:

.1 erected about 2 m above the timber deck cargo as

near as practicable to the centreline of the ship;

.2 stretched sufficiently taut with a tightening

device to support a fallen crewmember without collapse or failure.

Properly constructed ladders, steps or ramps fitted

with guard lines or handrails should be provided from the top of the cargo to

the deck, and in other cases where the cargo is stepped, in order to provide

reasonable access.

Action To

Be Taken During The Voyage

Tightening of lashings

It is of paramount importance that all lashings be

carefully examined and tightened at the beginning of the voyage as the vibration

and working of the ship will cause the cargo to settle and compact. They should

be further examined at regular intervals during the voyage and tightened as

necessary.

Entries of all examinations and adjustments to

lashings should be made in the ship’s logbook.