Cargo Work

Bulk Cargo (Grain)

Loading and Stowage of Bulk Grain

Before loading bulk the following preparations should

be done:

Holds and tween deck thoroughly swept down.

All dunnage removed from cargo spaces or stowed at one

and covered.

Bilges should be cleaned and sweetened

Bilges suctions should be tested

Tween deck scuppers should be covered with double

weave separation cloth, edges to be fixed with cement.

Any cracks between limber boards to be covered with

separation cloth nailed down to prevent the cargo from going into the bilges.

All pipelines passing through the bilges should be

tested and any leaks discovered should be fixed – esp. fire mains, water

ballast lines and bilge pumping out lines.

After the holds are swept and if required hosed down,

the holds/ compartments are to be inspected for any infestation.

The inspection should include all easily accessible

areas together with inaccessible areas including under the beams and hatch

pontoon frames. In case fumigation is carried out prior loading then the

compartment has to be swept and again inspected for any dead insects and

rodents. The fumigant used should be compatible with the cargo to be carried.

For loading of Rice the fumigation may be carried out

twice – prior loading and on completion of discharging.

The inspection for infestation should be very thorough

since apart from later claims, some ports especially in the

Shifting of

cargo

Certain bulk cargos have a tendency to shift and

precautions must be taken to counteract this tendency. These precautions are dealt with below:

Recommendation are made about the stowage of the

cargo:

Weight = db (3L+B) tonnes

4.6

where d is the summer load draft

b is average breadth of lower hold

L is length of lower hold

B is the maximum moulded breadth

The height of the cargo pile peak should not exceed:

1.89 x d x S. F. (m3/tonne) metres

Angle of repose

This is the greatest angle from the horizontal to

which a substance can be raised without it shifting. Cargoes most liable to

shift are those having a small angler of repose.

Angle of repose of 35˚ is taken as being the

dividing line for bulk cargoes of lesser or greater shifting hazard and cargoes

having angles of repose of more or less than this figure are considered

separately.

Trimming

In compartments entirely filled with bulk grain the

grain shall be trimmed so as to fill all the spaces between the beams and in

the wings and ends. In compartments

partly filled with bulk grain the grain shall be levelled whenever practicable.

The provision of a shifting boards or longitude

bulkheads within 5% of the vessel’s moulded breadth from the centre line or two

or more longitudinal bulkheads or shifting boards with a distance between of

not more than 60% of the vessel’s moulded breadth. In the latter case suitable sized trimming

hatches are to be provided in the wings at intervals of not more than 7.62m.,

the end hatches being not more than 3.66m from transverse bulkheads.

In holds the shifting boards must extend downwards

from the deck at least 2. 44m or ½ depth of hold whichever is the greater. In ‘tween decks and in feeders, unless there

is some exemption they must extend from deck to deck. If the compartment is only partly filled with

grain, the shifting boards must extend from the bottom of the compartment to at

0.6m above the surface of the bulk grain, however no shifting boards are

necessary if the bulk grain does not occupy more than ½ of the hold or ½ of the

hold where there is a shaft tunnel.

The Shifting boards must not be less than 50mm in

thickness and are to have a 80mm housing at the bulkhead. They must be adequately supported by wood

minimum size 250mm x 50mm or metal uprights with a maximum spacing of 3.96mm

and set in 80mm housings top and bottom.

The jointing of 50mm shifting boards must overlap by at least 230mm in

way of the uprights.

If the uprights are made sufficiently strong and the

length is not too great, shoring or

staying may be unnecessary. If wood shores are used they must be in a single

piece securely fixed at each end and heeled against the permanent structure of

the ship, but not directly against the side plating. The angle between the

shore and the horizontal should be kept as small as possible and must never

exceed 45˚.

The size of the shore is dependent upon its length; a

shore over 6.1m in length would be at least 200m x 150mm. If stays are used

they will be fitted horizontally and will consist of 75mm – 6 x 12 galvanised

flexible steel wire rope, secured with 25mm shackles to uprights and frames and

fitted with 32mm rigging screws in accessible positions.

If the uprights are not secured at the top, the

uppermost shore or stay is to be not less than 0.46m from the top.

The vertical spacing of the shores or stays is

obtained from tables in the rules.

GM

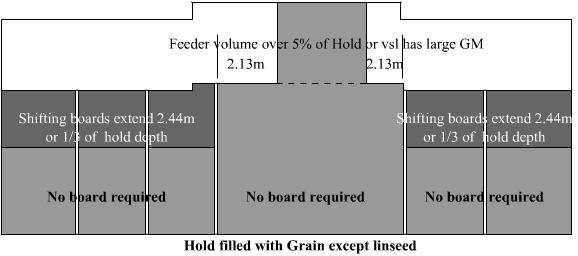

If a GM after correction for FSC of not less than

0.31m is maintained throughout the voyage in one or two deck ships or 0.36m in

other ships longitudinal bulkheads or shifting boards are not required in the

following positions, (except when linseed in bulk is being carried therein)

Below and within 2.13m of a feeder which contains not

less than 5% of the quantity of grain in the space it feeds, but only in way a

hatchway,

In feeders as above provided that the free grain

surface will remain within the feeders throughout the voyage allowing for a

sinkage of 2% of the volume of the compartment fed and a shift of the free grain

surface to 12˚,

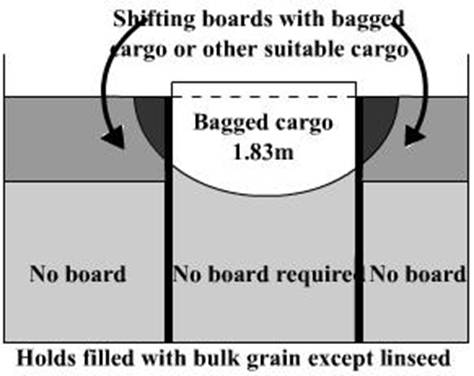

In way of the hatchway where the bulk grain has been

saucered, provided that the hatchway is filled with bagged grain or other

suitable bagged cargo. The minimum depth of the bagged cargo in the centre of

the saucer to be 1.83m below the deck level. The grains to be stored tightly up

to the deck head in the other parts of the compartment,

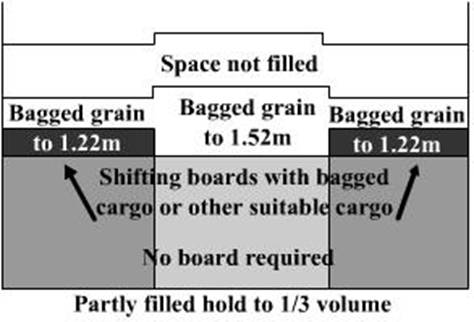

In way of a hatchway in a compartment partly filled

with bulk grain.

The surface of grain in a partly filled compartment is

to be saucered with a minimum height of 1.52m of bagged grain or other suitable

cargo over the portion where there are no shifting boards and 1.22m where there

are shifting boards. This latter height is also required when the bulk grain

does not occupy more than 1/3 of the hold or ½ of the hold where there is a

shaft tunnel.

The bagged grain shall be carried in sound bags, which

shall be securely closed and well filled. The bags or other suitable cargo

shall be supported on suitable platforms which consist of strong separation

cloths with adequate overlapping or 25mm boards spaced not more that 100mm

apart laid on bearers not more than 1.22m apart.

Feeders are to be fitted to feed compartments entirely

filled with bulk grain, except in deep tanks not over ½ moulded breadth of vessel

in case ‘GM c’ above.

They are to contain not less than 2% of the quantity

of grain carried in the compartment, which they feed. The boarding may be

horizontal or vertical but must be sufficiently supported by binders, shores or

stays as laid down in the rules. Feeding holes are to be provided about 0.61m

apart in coamings, which extend more that 0.39m below the deck. The diameter of

the hole is 50mm or 88mm depending on coaming depth. Feeders are assumed to be

capable of feeding a distance of 7.62m.

If any part of the compartment is more that 7.62m

(measured in a fore and aft line) from the nearest feeder, the grain in the

space beyond 7.62m is to be levelled off at a depth of at least 1.83m below the

deck and the space above is to be filled with bagged grain or suitable cargo.

Loading two

different cargoes in the same hold

Very occasionally, different types of grain are loaded

into the same hold. The heavier grain is loaded first and trimmed level over

the entire area of the hold. The surface is covered with separation cloths/

canvas, allowing for ample overlaps, at least 1m. The cloths are carried well

up the sides and ends of the compartment so that the next grain loaded will

force them against the plating between the frames and stiffeners, it has to be

ensured that adequate leeway is allowed for the separation cloth being taken up

the sides and ends of the compartment, since the lower cargo would settle down

during the voyage and if this leeway is not allowed for the cloth would exert a

pull and tear off from the side moorings. This would result in the cargo being

mixed.

The lighter grain should be loaded carefully at first

to avoid displacing the separation cloths. Once the lighter cargo has been

leveled off to a height of 0.5m all over the loading may begin at the usual

rate, care being taken to see that it is constantly leveled by adjusting the

loading chute inflow direction.

When bulk grain is carried in the ‘tween deck of a two

deck ship or in the upper ‘tween deck of a ship having more than two decks or

above deck the following are to be complied with:

Either the GM shall not be less than that specified in

paragraph ‘GM’ or the total quantity of bulk grain or other cargo carried in

the specified space shall not exceed 28% by weight of the total cargo below the

‘tween deck.

Partly filled deck area in the above space is not to

exceed 93m2,

The spaces which contain bulk grain are to be divided

into lengths of not more than 30.5m by transverse bulkheads, or if not so

divided the excess space – beyond 30.5m is to be entirely filled with bagged

grain or other suitable cargo.

Vessels having a GM less than that specified in

paragraph ‘GM’ are not permitted to have more than two holds or compartments

partly filled with bulk grain wherein the overstowing cargo does not fill the

space to the deck head. Feeders are not compartments and so they are exempted

from this requirement.

Double bottom tanks used to meet a stability

requirement are to be adequately subdivided longitudinally unless the width of

the tank at its ½ length does not exceed 60% of the vessel’s moulded breadth.

A grain-loading plan may be supplied to certain ships,

which may then be exempted from some of the provisions outlined above due to

their special construction (such as tanker and bulk carriers), which prevents

shifting of the bulk cargo. However, the resulting list of the vessel must not

exceed 5˚ if the grain settles by 2% and shifts to an angle of 12˚

from its original position.