| Grain Cargo | Cargo Care | IMDG | Cargo Handling Equipment | Cargo Handling Safety | |

| Oil Tanker | Cargo Measurement | Enclosed Spaces |

Cargo Work

Bulk Cargo (Not Grain)

Bulk

cargoes (other than grain)

The officer of the watch should know the pre-planned loading procedure regarding quantities to be loaded in each space, the order of deballasting tanks and shifting the vessel under loading chutes. The procedure will have been worked out to keep stresses within acceptable limits and to finish with a satisfactory weight distribution and trim. The officer of the watch should see that the plan is followed, particularly at berths with only one loading chute, to avoid over-stressing the ship.

Code of Safe Practice for Solid Bulk Cargoes BC Code

is intended to set a standard for the safe stowage and carriage of solid bulk

cargoes.

This Code is a recommended guide for ship owners,

shippers and masters and shall apply to all shipments of bulk cargoes.

The list of products appearing in the Appendices of

the BC Code, however, is by no means exhaustive. Consequently, before any bulk

cargo is loaded, it is essential to ascertain (normally from the shipper) the

current physical and chemical properties of the cargo, as required under SOLAS

Chapter VI.

General requirements

Before and during loading, transport and unloading of

bulk cargoes, all necessary safety precautions including any regulations or requirements

should be observed, including the following:

1. Dangerous Bulk Material Regulations

2. Safe Working Practices Regulations

3. International Maritime Dangerous Goods Code (IMDG

Code)

4. Emergency Procedures For Ships Carrying Dangerous

Goods

5. Medical First Aid Guide for Use in Accidents

Involving Goods (MFAG)

6. IMO BC Code - Code of Safe Practice for Solid Bulk

Cargoes

Poisoning and asphyxiation hazards

Certain bulk cargoes are liable to oxidation, which in

t urn may result in oxygen depletion, emission of toxic fumes and self-heating.

Other bulk cargoes may not oxidize but may emit toxic fumes.

It is important therefore that the shipper inform the

master before loading of the existence of any chemical hazards. The master

should refer to Appendix B of the BC Code and take the necessary precautions,

especially those pertaining to ventilation.

Certain cargoes may emit toxic gases when wetted. In

these cases the ship should be provided with the appropriate gas detection

equipment.

A flammable gas detector is only suitable for testing

the explosive nature of gas mixtures.

Emergency entry into a cargo space should be

undertaken only by trained personnel wearing self-contained breathing

apparatus, and protective clothing if considered necessary, always under the

supervision of a responsible officer.

In the event of emergency entry into a cargo space, in

addition to the above requirement, spare self-contained breathing apparatus,

safety belts and safety lines should be readily available.

Health hazard from dust

To minimize the chronic risks from exposure to the

dust of certain materials carried in bulk, a high standard of personal hygiene

for those exposed to the dust cannot be too strongly emphasized. The

precautions should include not only the use of appropriate protective clothing

and barrier creams when needed but also adequate personal washing especially

before meals, and laundering of outer clothing.

Flammable atmosphere

Dust created by certain cargoes may constitute an

explosion hazard, especially, during loading, unloading and cleaning. This risk

can be minimized at such times by ensuring that ventilation is sufficient to

prevent the formation of a dustladen atmosphere and by hosing down rather than

sweeping.

CARGOES

THAT MAY LIQUEFY (section 7 of the BC Code)

Properties, characteristics and hazards

Cargoes that may liquefy include concentrates, certain

coals and other materials having similar physical properties. Appendix A of the

BC Code contains a list of such cargoes, which generally consist of a mixture

of small particles in contrast with natural ores that include a considerable

percentage of large particles or lumps.

Section 5 of the BC Code - Trimming Procedures

At moisture content above that of the transportable

moisture limit, shift of cargo may occur as a result of liquefaction.

The major purpose of the sections of this Code dealing

with these cargoes is to draw the attention of masters and others to the latent

risk of cargo shift, and to describe the precautions deemed necessary to

minimize this risk.

Such cargoes may appear to be relatively dry and

granular when loaded, but may contain sufficient moisture as to become fluid

under the stimulus of compaction and the vibration that occurs during a voyage.

In the resulting viscous fluid state, cargo may flow

to one side of the ship when it rolls one way, but not completely return when

it rolls the other. Thus, the ship sways progressively until it reaches a

dangerous heel and capsizes.

To prevent subsequent shifting, and also to decrease

the effects of oxidation of material with a predisposition to oxidize, these

cargoes should be trimmed reasonably level on completion of loading,

irrespective of the angle of repose.

Amended

Extract from SOLAS Chapter VI

Part B

Special

provisions for bulk cargoes other than grain

Regulation

6

Acceptability

for shipment

Concentrates or other cargoes which may liquefy shall

only be accepted for loading when the actual moisture content of the cargo is

less than its transportable moisture limit. However, such concentrates and

other cargoes may be accepted for loading even when their moisture content

exceeds the above limit, provided that safety arrangements to the satisfaction

of the Administration are made to ensure adequate stability in the case of

cargo shifting and further provided that the ship has adequate structural

integrity.

Prior to loading a bulk cargo which is not a cargo

classified but which has chemical properties that may create a potential

hazard, special precautions for its safe carriage shall be taken.

Regulation

7

Loading,

unloading and stowage of bulk cargoes

To enable the master to prevent excessive stresses in

the ship’s structure, the ship shall be provided with a booklet, which shall be

written in a language with which the ship’s officers responsible for cargo

operations are familiar. The booklet shall, as a minimum, include:

.1 stability data,

.2 ballasting and de-ballasting rates and capacities;

.3 maximum allowable load per unit surface area of the

tank top plating;

.4 maximum allowable load per hold;

.5 general loading and unloading instructions with

regard to the strength of the ship’s structure including any limitations on the

most adverse operating conditions during loading, unloading, ballasting

operations and the voyage;

.6 any special restrictions such as limitations on the

most adverse operating conditions imposed by the Administration or organization

recognized by it, if applicable; and

.7 where strength calculations are required, maximum

permissible forces and moments on the ship’s hull during loading, unloading and

the voyage.

Before a solid bulk cargo is loaded or unloaded, the

master and the terminal representative shall agree on a plan* which shall

ensure that the permissible forces and moments on the ship are not exceeded

during loading or unloading, and shall include the sequence, quantity and rate

of loading or unloading, taking into consideration the speed of loading or

unloading, the number of pours and the de-ballasting or ballasting capability

of the ship. The plan and any subsequent amendments thereto shall be lodged

with the appropriate authority of the port State.

Bulk cargoes shall be loaded and trimmed reasonably

level, as necessary, to the boundaries of the cargo space so as to minimize the

risk of shifting and to ensure that adequate stability will be maintained

throughout the voyage.

When bulk cargoes are carried in ‘tween-decks, the

hatchways of such ‘tween-decks shall be closed in those cases where the loading

information indicates an unacceptable level of stress of the bottom structure

if the hatchways are left open. The cargo shall be trimmed reasonably level and

shall either extend from side to side or be secured by additional longitudinal

divisions of sufficient strength. The safe load-carrying capacity of the ‘tween-decks

shall be observed to ensure that the deck-structure is not overloaded.

The master and terminal representative shall ensure

that loading and unloading operations are conducted in accordance with the

agreed plan.

If during loading or unloading any of the limits of

the ship are exceeded or are likely to become so if the loading or unloading

continues, the master has the right to suspend operation and the obligation to

notify accordingly the appropriate authority of the port State with which the

plan has been lodged. The master and the terminal representative shall ensure

that corrective action is taken. When unloading cargo, the master and terminal

representative shall ensure that the unloading method does not damage the

ship’s structure.

The master shall ensure that ship’s personnel

continuously monitor cargo operations. Where possible, the ship’s draught shall

be checked regularly during loading or unloading to confirm the tonnage figures

supplied. Each draught and tonnage observation shall be recorded in a cargo

logbook. If significant deviations from the agreed plan are detected, cargo or

ballast operations or both shall be adjusted to ensure that the deviations are

corrected.

At a moisture content above that of the transportable

moisture limit, shift of cargo may occur as a result of liquefaction.

Many cargoes may appear to be relatively dry and

granular when loaded, but may contain sufficient moisture as to become fluid

under the stimulus of compaction and the vibration that occurs during a voyage.

In the resulting viscous fluid state, cargo may flow

to one side of the ship when it rolls one way, but not completely return when

it rolls the other. Thus, the ship way progressively reaches a dangerous heel

and capsize.

Ships other than specialist suited ones shall carry

only those cargoes having a moisture content that is not in excess of the

transportable moisture limit as defined in this Code.

Specially suited ships

Specially suited ships may carry concentrates having a

moisture content in excess of the transportable moisture limit if the ship

possesses a valid document of approval from her administration, accompanied by

such stability information as her administration may require. The document of

approval must clearly state “For carriage of concentrates having a moisture

content in excess of the transportable moisture limit”.

When concentrates are loaded that have a moisture

content in excess of the transportable moisture limit, the whole surface area

of each cargo space shall be trimmed level.

Cargoes having a moisture content in excess of the

flow moisture point shall not be carried in bulk.

Before loading, the shipper or his appointed agents

shall provide to the master and the port warden, if requested, details, as

appropriate, of the characteristics and properties of any material constituting

bulk cargo, such as flow moisture point, stowage factor, moisture content,

angle of repose, chemical hazards, etc. so that any necessary safety

precautions can be put into effect.

To do this the shipper shall arrange, possibly in

consultation with the producers, for the cargo to be properly sampled and

tested. Furthermore, the shipper should provide the ship’s master and the port

warden, if requested, with the appropriate certificates of test, as applicable

for a given cargo.

Before and during loading, auxiliary check tests of

the moisture content may be carried out using instruments designed specifically

for that purpose, such as the “SPEEDY MOISTURE TESTER”. Tests conducted with

this instrument indicate a precision of ±1% compared with the laboratory

method, i.e., with a laboratory reading of 10%, the “SPEEDY” reading could

range from, 9% to 11%. If the readings obtained by this method are consistently

higher than those shown on the certificate, loading of the cargo should cease

and a further laboratory test be conducted.

If the master has doubts as regards the appearance of

condition of the cargo for safe shipment, the following auxiliary method may be

used on board ship or at the dockside to perform a check test for approximately

determining the possibility of flow:

Half fill a cylindrical can or similar container

(0.5-1 litre capacity) with a sample of cargo. Take the can in one hand and

bring it down sharply from a height of about 0.2m to strike a hard surface such

as a solid table. Repeat the procedure twenty-five times at one or two second

intervals. Examine the surface for free moisture or fluid conditions. If free

moisture or a fluid condition appears, make arrangements to have additional

laboratory tests on the cargo conducted before it is accepted for loading.

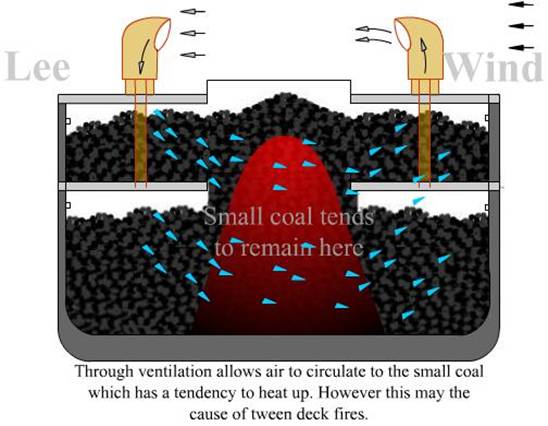

COAL is very

liable to spontaneous heating. If there

is sufficient oxygen available, combustion is liable to take place. The amount

of heating that takes place depends on the type of type coal and how much heat

can be dispersed by ventilating the coal.

Ventilation can be a double-edged weapon as although it takes heat from

the coal it also allows unwanted oxygen into the coal. To keep the coal as cool as possible it

should be stowed away from hot bulkheads.

To keep oxygen away from the coal only surface ventilation should be

allowed.

All spar ceiling or cargo battening should be removed

as besides the liability of it to damage, it can give unwanted air pockets in

the coal. Unwanted air may also get into

a cargo through a temporary wooden bulkhead. If such a bulkhead has been

constructed all cracks should be sealed, preferably by pasting paper over both

sides of the bulkhead.

Freshly mined coal absorbs oxygen, which, with

extrinsic moisture, forms peroxides.

These in turn breakdown to form carbon monoxide and carbon dioxide.

Heat is produced by this exothermic reaction causing

further oxidation and further heat. If

this heat is not dissipated ignition will occur. This is called Spontaneous combustion.

As this is essentially a surface reaction the smaller

the surface available for the absorption of oxygen the better. Every attempt

should be made to prevent undue breakage of the coal whilst it is being loaded.

It may be noted that 1 MT of coal in an unbroken cube has a surface area of

about 3.72m2, whereas if it is broken up to pass through a 1.5mm mesh screen

its surface area is nearly 4000m2. If a large amount of breakage occurs the

small coal with the large surface area is found in the centre of the hold,

whilst the large coal will roll down the sides. This aggravates the situation,

as the large coal gives a good path for air to flow to the smaller coal where

the spontaneous heating is most liable to occur.

Most coal fires in cargo occur at about ‘tween deck

level and this is the area where the greatest attention should be paid to

temperature and the restriction of through ventilation.

The following are recommendations for the carriage of

coal.

The ventilators to the lower holds should be so arranged

that they might be opened or closed at will during the voyage.

As the critical temperature at which the process of

spontaneous heating in coal becomes greatly accelerated is in some varieties of

coal as low as 36˚C, and generally is not much higher, the need of keeping

the exteriors surface of the hull, and thereby the interior of the ‘tween decks

and holds, as cool as possible is manifest.

The iron decks of ships carrying coal in the tropics can be covered with dunnage to lessen heating.

Suitable means should be provided for ascertaining

from time to time the temperature of the lower mass of coal, particularly below

the hatchways, and this might be done by means of two pipes leading down to the

bottom of the coal at each hatchway.

The temperature tubes should have closed ends to

prevent admission of air into the cargo. The temperature of the coal at three

heights should be taken daily.

Gas from the holds or ‘tween decks space may find its

way into shaft, peaks, chain lockers or similar space unless the bulkheads and

casings are maintained in gas tight conditions.

Naked lights should not be used in holds or other

spaces in which gas may accumulate until the spaces have been well ventilated.

Full use should, when necessary, be made of the

breathing apparatus or smoke helmet and the safety lamp, which form part of the

ship’s statutory fire appliances.

The employment of the crew in chipping and painting

below decks during the voyage should be avoided. The danger from smoking should be realized

and no oily waste, wood, old rope, sacking etc. should be left below where it

can become ignited by spontaneous heating

On arrival at the port of discharge the hold

ventilators should be unplugged and the lower hold well ventilated before

commencing to work cargo.

Coal is frequently loaded from a single tip and

earlier it was necessary to drift the vessel

fore and aft so that all holds may be filled. To keep these shifts to a minimum No.2 was

first put under the tip.

After about one third the capacity of the hold was

loaded the vessel was shifted so that No. 3 was loaded to about one third of

its capacity. Likewise the remaining

after holds were loaded and then the tip was shifted astern to reach No. 1,

half the capacity was put in, before shifting to No. 2, which was then

filled.

The other after holds were now filled in order

excepting the aftermost. The aftermost hold and the No.1 were now worked so

that the vessel would complete loading in a good trim.

Coal is sometimes graded, when this in so, care should

be taken to prevent undue breakage.

Lowering the first few truckloads into the hold helps

as do control of the rate of tipping down and chute.

Some ports have conveyor belts and an endless bucket

system for loading; this is excellent for graded coal and also keeps the dust

down with the ordinary coal.

Fortunately it is mainly the better coals, which are

graded, and in generally these are not so friable.

Coal will need to be trimmed and its angle of repose

is quite high, especially if large coal is loaded.

There is no danger for coal shifting unless it is the

very small stuff known as mud coal, slurry or duff.

This is very fine coal, almost dust, and if the

moisture content is high it behaves almost like a liquid.