| Grain Cargo | Cargo Care | IMDG | Cargo Handling Equipment | Cargo Handling Safety | |

| Oil Tanker | Cargo Measurement | Enclosed Spaces |

Cargo Work

Cargo Measurement

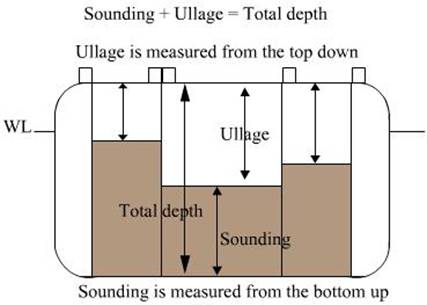

Tank quantities are measured by noting the level of

the fluid in the tank and then referring to the tank calibration tables and

noting down the quantity specified against that level.

Thus we take the sounding of a tank water and fuel

on all type of ships and then follow the above practice. Note that prior to

referring to the tables the tank level has to be corrected for error due to

trim and list. These corrections are generally given in the tank calibration

tables.

The above method though fine by all are turned upside

down on a tanker. A tanker loads oil and it is not feasible to take a sounding

every now and then besides it is very messy. On tankers therefore instead of

sounding the reverse is measured that is the vacant level to reach the top of

the tank or the ullage.

Thus ullage tables are nothing but the sounding table

reversed.

Note the following:

The maximum sounding of a tank is 24.35m the maximum

ullage is also 24.35m.

When the sounding is 10m the ullage would be 24.35

10 = 14.35m

Thus when a tank is filling up the sounding increases,

whereas the ullage reduces.

Once the liquid level is obtained the same is seen for

the quantity (Volume) in the calibration book.

This is the Gross volume at Natural Temperature GVn

(observed temperature being taken of the liquid at three levels and then

averaged)

The sounding of any water which may be present in the

tanks is now taken (some water is usually present in crude oil and also

sometimes in product oil). The calibration tables are again referred and the

volume of Free Water is obtained.

Thus the Net Volume at Natural (NVn) is found by

subtracting the water form the GVn.

This NVn is now converted to a volume at 15˚C by

looking up the correction in the ASTM tables a factor is found, which

converts the Volume at Natural temperature to a volume at 15˚C.

This would then be the Net volume of oil loaded.

The conversion is required since the loading

temperature may be 40˚C whereas the temperature of the oil after a voyage

of 30 days would drop to about 30˚C or so. Obviously the volume would then

contract, so a standard temperature correction is done to 15˚C at both the

load as well as the disport.

For weight calculations the volume at 15˚C is

taken and this is multiplied by the density at 15˚C of the oil (actually a

factor which is 0.0011 less than the density at 15˚C is used)

Bale

Capacity:

This is the cubic capacity of a space when the breadth

is taken from the inside of the cargo battens, the depth from the wooden

ceiling to the underside of the deck beams and the length from the inside of

the bulkhead stiffeners or sparring where fitted.

Grain

Capacity:

This is the cubic capacity of a space when the

lengths, breadths and the depths are taken right to the ships side plating. An

allowance is usually made for the volume occupied by frames and beams.

Stowage

Factor:

This is the volume occupied by unit weight of cargo.

Usually expressed as cubic metres/ tonne. It does not take into account space,

which may be lost due to broken stowage. However it obtained by multiplying the

greatest length by the greatest breadth with the greatest height.

Example:

A bale of Hessian has the following dimensions: L

1.2 M, B 1.2 M and H 1.5 M. The bale weighs 800 KGS.

The SF then would be obtained by:

Volume: L x B x H = 1.2 x 1.2 x 1.5 = 2.16 CBM

So, 2.16 CBM would weigh 0.8 MT

Or 1 MT of the cargo in bales would occupy 2.7 CBM

Broken

Stowage:

The space between packages which remains unutilized.

This is generally expressed as a percentage and the amount that is to be

allowed varies with differ rent cargo and the shape of the hold. It is greatest

when large cases have to be loaded in a n end hold, where the after end narrows

down considerably.

BS is generally not given in any of the booking lists,

but is a ship/ hold experience factor or a sister ship experience factor for

that particular cargo. The most commonly accepted figure is about 10%, thus

with a BS of 10% the available cargo space that may be loaded would be 90%.

Example: Given to

load a quantity of light packaged cargo having a SF at 2.7 CBM/MT, the hold

space (bale capacity) is given as 885 CBM. To find the amount of cargo that may

be loaded in the hold.

The bale capacity is 885 CBM but since the BS is 10%

the available space would be 885 x 90% Or 796.5 CBM Thus the cargo that can be

loaded would be 796.5/ 2.7 = 295 MT (about).

However this BS that is given is for a proper stow as per earlier

estimates, the final stow should also be a good stow or the BS that would be

obtained on final completion would vary.

Thus on final completion of loading if the tween deck

was loaded with only 275 MT then the BS that was obtained would be:

Full capacity 885 CBM at 2.7 CBM/ MT could take in

885/ 2.7 = 328 MT

But it finally took in only 275 MT thus had a

shortfall was 53 MT which was due to BS.

Thus,

328 MT 275 MT = 53

And 53 / 328 =

0.16

Expressed as a percentage = 16% was lost due to BS

instead of the earlier estimated figure of 10%.

Example-101

Given to load No. 1 Lower Hold

Bale capacity 962 m3

Max Height 11.945m

Permissible Load 9.2 t/ m2

Forward Breadth 4.5m

After Breadth 11.5m

Mean Breadth 8m

Length 10.5m

Area of the hold Length x Mean Breadth

A = 11 x 8 = 88m2

Permissible Load density 9.2 t/m2

Therefore the load if evenly spread all over the hold

would enable the hold to be loaded with:

88 x 9.2 = 809.6 MT

Example-102

Given to load No. 1 Lower Hold

Bale capacity 962 m3

Max Height 11.945m

Permissible Load 9.2 t/ m2

Forward Breadth 4.5m

After Breadth 11.5m

Mean Breadth 8m

Length 10.5m

Cargo SF 2.7 m3/t

Volume 962 m3

Cargo can load Volume/ SF

Cargo to load 962/ 2.7

Cargo to load 356 MT

Example-103

Given to load No. 1 Lower Hold

Bale capacity 962 m3

Max Height 11.945m

Permissible Load 9.2 t/ m2

Forward Breadth 4.5m

After Breadth 11.5m

Mean Breadth 8m

Length 10.5m

Cargo 150 MT, SF 2.7 m3/t to load only in after half

of the hatch space

After breadth 11.5m

Mid Breadth 8m

Mean breadth 9.75m

½ Length 5.25m

Area of ½ hold as above 51.2 m2

Volume of above 611 m3

Max permissible load on 51.2 m2 9.2 x 51.2 = 471 MT

Since the cargo has a SF of 2.7 m3/t the volume

occupied by the cargo would be:

Volume/ SF

611/ 2.7 = 226 MT

So the after half of the hold would take in 226 MT of

the cargo and would remain within the permissible load density.

Let us now fill up the forward half of the hold with a

cargo having a SF of 0.8 m3/t (heavy cargo)

Cargo ?? MT, SF 0.8 m3/t to load in forward half of

the hatch space

After breadth 4.5m

Mid Breadth 8m

Mean breadth 6.25m

½ Length 5.25m

Area of ½ hold as above 32.8 m2

Volume of above 392 m3

Permissible load would be: 32.8 m2 x 9.2 (SF) = 302 MT

Cargo that could be loaded as per SF Volume/ SF =

392/ 0.8 = 490 MT

But the permissible load is 302 MT, so the cargo

could not be loaded right up to the top of the hold. So there would be a height

restriction.

First we find the Volume as required for the

permissible load of 302 MT

Load 302 = Volume/ 0.8

Or Volume = 302 x 0.8 = 242 m3

Since we know the area as 32.8 m2 we can find the

height,

Volume/ Area or 242/ 32.8 = 7.4 m

Thus the

cargo of 302 MT could be loaded only up to a height of 7.4m.