| Grain Cargo | Cargo Care | IMDG | Cargo Handling Equipment | Cargo Handling Safety | |

| Oil Tanker | Cargo Measurement | Enclosed Spaces |

Cargo Work

Dangerous Goods

Classes,

divisions, packing groups

Definitions

Substances (including mixtures and solutions) and

articles subject to the provisions of this Code are assigned to one of the

classes 1 -9 according to the hazard or the most predominant of the hazards

they present. Some of these classes are

subdivided into divisions. These classes

or divisions are as listed below:

Class 1:

Explosives

Division 1.1: substances and articles, which have a

mass explosion hazard

Division 1.2: substances and articles, which have a

projection, hazard but not a mass explosion hazard

Division 1.3: substances and articles, which have a

fire hazard and either a minor blast hazard or a minor projection hazard or

both, but not a mass explosion hazard

Division 1.4: substances and articles, which present

no significant hazard

Division 1.5: very insensitive substances, which have

a mass explosion hazard

Division 1.6: extremely insensitive articles which do

not have a mass explosion hazard

Class 2:

Gases

Class 2.1: flammable gases

Class 2.2: non-flammable, non-toxic gases

Class 2.3: toxic gases

Class 3:

Flammable liquids

Class 4:

Flammable solids; substances liable to spontaneous combustion; substances

which, in contact with water, emit flammable gases

Class 4.1: flammable solids, self-reactive substances

and desensitized explosives

Class 4.2: substances liable to spontaneous combustion

Class 4.3: substances, which, in contact with water,

emit flammable gases

Class 5:

Oxidizing substances and organic peroxides

Class 5.1: oxidizing substances

Class 5.2: organic peroxides

Class 6:

Toxic and infectious substances

Class 6.1: toxic substances -

Class 6.2: infectious substances

Class 7:

Radioactive material

Class 8:

Corrosive substances

Class 9:

Miscellaneous dangerous substances and articles

The numerical order of the classes and divisions is

not that of the degree of danger.

Marking, labelling and placarding

Packages containing dangerous goods shall be durably

marked with the correct technical name; trade names alone shall not be used.

Packages containing dangerous goods shall be provided

with distinctive labels or stencils of the labels, or placards, as appropriate,

so as to make clear the dangerous properties of the goods contained therein.

The method of marking the correct technical name and

of affixing labels or applying stencils of labels, or of affixing placards on

packages containing dangerous goods, shall be such that this information will

still be identifiable on packages surviving at least three months’ immersion in

the sea. In considering suitable marking, labelling and placarding methods,

account shall be taken of the durability of the materials used and of the

surface of the package.

Packages containing dangerous goods shall be so marked

and labeled except that:

.1 packages containing dangerous goods of a low degree

of hazard or packed in limited quantities or

.2 when special circumstances permit, packages that

are stowed and handled in units that are identified by labels or placards; may

be exempted from labelling requirements.

General

information prior loading/ discharging

The duty officer entrusted with the loading of the

dangerous goods should have all the relevant data regarding the dangerous goods

that would be loaded, these would include:

Copy of the document from the shipper regarding the

cargo

Classification of the DG

Quantity to be loaded

Proposed stowage

Type of packages

Shipping name – that is the correct technical name

Segregation required from other cargo as well as from

other DG

MFAG and EmS requirement for the safe handling of the

cargo

Any fire hazard as per IMDG

Any temperature/ wetness restriction for the loading

of the cargo

UN Numbers

and Proper Shipping Names

Dangerous goods are assigned to UN Numbers and Proper

Shipping Names according to their hazard classification and their composition.

Dangerous goods commonly transported are listed in the

Dangerous Goods List. Where an article or substance is specifically listed by

name, it should be identified in transport by the Proper Shipping Name in the

Dangerous Goods List. For dangerous

goods not specifically listed by name, “generic” or “not otherwise specified”

entries are provided to identify the article or substance in transport.

Each entry in the Dangerous Goods List is assigned a

UN Number. This list also contains

relevant information for each entry, such as hazard class, subsidiary risk(s)

(if any), packing group (where assigned), packing and tank transport

provisions, EmS, segregation and stowage, properties and observations, etc.

Entries in the Dangerous Goods List are of the

following four types:

Single entries for well-defined substances or articles

e.g.

UN 1090

acetone

UN 1194

ethyl nitrite solution

Generic entries for well-defined groups of substances

or articles e.g.

UN 1133

adhesives

UN 1266

perfumery product

Information

on the special measures to be taken when a certain dangerous cargo is handled

Additionally the chief officer should have attached

relevant extracts from the IMDG code in particular all the emergencies that

could arise with the handling of the cargo. Also the emergency clean-up

measures as well as the first aid requirement as per the

Any special precautions mention as per the Dangerous

List should be extracted. Compatibility risks should be ascertained.

For example if the following cargo (class 3) is to be

loaded, then:

Stowage of

goods of class 3

The vapours from all substances of class 3 have a

narcotic effect, and prolonged inhalation may result in unconsciousness. Deep or prolonged narcosis may lead to death.

Class 3 substances should be stowed as indicated in

the Dangerous Goods List. However, substances with a flashpoint of 23˚C

(c.c). or less packaged in jerricans, plastics (3Hl, 3H2), drums, plastics

(lHl,lH2) and plastics receptacles in a plastic drum (6HH1,6HH2)should be

stowed on, deck only unless packed in a closed cargo transport unit.

The substances of this class should be kept as cool as

reasonably practicable during transit.

They should, in general, be stowed “away from” all possible sources of

heat.

Adequate precautions should be taken to protect the

flammable liquids from heat emanating from bulkheads or other sources. Ventilation should be provided which should

effectively remove flammable vapours from the cargo space.

Adequate measures should be taken to prevent the

penetration of leaking liquid or vapour into any other part of the ship. Vapours may not necessarily be lighter than

air and may sink to the lower levels of a cargo space where they may be

accidentally ignited and a “flashback” to the flammable liquids may occur.

Whenever flammable liquids with a flashpoint of

23˚C c.c. or less are transported in portable tanks, the stowage should be

such that leaking vapours are unlikely to penetrate the accommodation,

machinery spaces and other work areas via entrances or other openings in

bulkheads or through ventilation ducts.

Where it is deemed necessary for a substance of this

class to be stowed “clear of living quarters”, it is included in the Dangerous

Goods List.

On ships carrying passengers, substances in this class

should be stowed well away from any deck or spaces provided for the use of

passengers. When such substances are

transported on board roll-on/roll-off ships, see chapter 7.4.

End extract

Reporting of incidents involving dangerous goods

When an incident takes place involving the loss or

likely loss overboard of packaged dangerous goods into the sea, the master, or

other person having charge of the ship, shall report the particulars of such an

incident without delay and to the fullest extent possible to the nearest

coastal State. The report shall be based on the guidelines and general

principles adopted by IMO for dangerous goods, harmful substances and/or marine

pollutants.

In the event of the ship referred to in paragraph 1

being abandoned, or in the event of a report from such a ship being incomplete

or unobtainable, the owner, charterer, manager or operator of the ship, or

their agents shall, to the fullest extent possible, assume the obligations

placed upon the master by this regulation.

The duty officer when he discovers an incident or

accident has to immediately raise the alarm and inform the Master regarding the

same. The crew on deck should be the first to renders assistance as well as

start the clean up operations as well as try to minimise the incident under the

supervision of the duty officer as per the guidelines laid down for that cargo

as per the IMDG code and the Dangerous cargo list.

Actions to

be taken

All actions after an accident are to be as per the

following documents – which have detailed instructions for all types of

emergencies.

The following gives a basic layout of a rescue

scenario.

The IMO/WHO/ILO Medical First Aid Guide for Use in

Accidents Involving Dangerous Goods (MFAG) is the Chemicals Supplement to the

International Medical Guide for Ships (IMGS), which is published by the World

Health Organization (WHO),

The Maritime Safety Committee adopted this revised

text of the Guide in May 1998, for use in association with Amendment 30-00 of

the IMDG Code, and will be further amended as and when, necessary.

Table 1

RESCUE

Rescuers must be adequately protected from exposure

before entering a contaminated area in order to avoid injury.

When a chemical is unidentified, worst-case

assumptions concerning toxicity must be assumed.

ARRIVAL AT SCENE

Upon arrival at the scene, an initial assessment of

the situation should be made and the size of the incident should be determined.

Rescuers must NOT:

Enter a contaminated area without using a

pressure-demand self-contained breathing apparatus and wearing full protective

clothing;

Enter an enclosed space unless they are trained

members of a rescue team and follow correct procedures;

Walk through any spilled materials;

Allow unnecessary contamination of equipment;

Attempt to recover shipping papers or manifests from

contaminated area unless adequately protected;

Become exposed while approaching a potentially

contaminated area;

Attempt rescue unless trained and equipped with

appropriate personal protective equipment (PPE) and protective clothing for the

situation.

QUICKLY ESTABLISH AN EXCLUSION OR HOT ZONE

Assume that anyone leaving the exclusion zone is

contaminated and should be assessed and decontaminated, if necessary.

Do not remove non-ambulatory casualties from the

exclusion zone unless properly trained personnel with the appropriate PPE are

available and decontamination has been accomplished.

INITIAL TRIAGE OF CASUALTIES (SORTING AND PRIORITY)

One unconscious casualty

Give immediate treatment to the unconscious casualty

only, and

Send for help.

Several unconscious casualties

If there is more

than one unconscious casualty:

Send for help, and

Give appropriate treatment to the worst casualty in

the priority order of:

Casualties who have stopped breathing or have no pulse

(see Table 2).

Casualties who ARE UNCONCIOUS (see Table 4).

Casualty is unconscious but breathing

If the casualty is unconscious or cyanotic (bluish

skin) but breathing, connect to portable oxygen.

Neck or back trauma

Apply neck and back support before moving casualty if

there is any question of neck or back trauma. Priority. Airway, Breathing, Circulation (A-B-C)

Initial management of Airway, Breathing and

Circulation (A-B-C, see table 2) is all that should be undertaken while there

is potential for further injury to the casualty or to response personnel.

Gross decontamination

If the casualty is contaminated with chemicals, gross

decontamination should be performed.

Cut away or remove all suspected contaminated

clothing, including jewellery and watches.

Brush or wipe off any obvious contamination.

Care should be taken to protect open wounds from

contamination.

Every effort should be made by personnel to avoid

contact with potentially contaminated casualties. Rescuers should wear protective clothing, if

necessary.

Cover or wrap casualty to prevent spread of

contamination.

Removal of casualties from exclusion zone

Once gross decontamination has been performed, the

casualties should be removed from the exclusion zone.

If casualties can walk, lead them out of the exclusion

zone to an area where decontamination and further evaluation can take place.

If casualties are unable to walk, remove them on

stretchers. If stretchers are

unavailable, carefully carry or drag casualties to an area where

decontamination and further evaluation can take place.

DECONTAMINATION

Decontaminate from head down

Take care not to introduce contaminants into open

wounds.

Decontaminate exposed wounds and eyes before intact

skin areas.

Cover wounds with a waterproof dressing after

decontamination.

For external contamination, begin with the least

aggressive methods

Limit mechanical or chemical irritation of the skin.

Wash contaminated area gently under a stream of water

for at least ten minutes, and wash carefully with soap and warm (never hot)

water, scrubbing with a soft brush or surgical sponge.

Reduce level of contaminants

Remove contaminants to the level that they are no

longer a threat to casualty or response personnel.

Isolate the casualty from the environment to prevent

the spread of any remaining contaminants. Contain runoff; bag contaminated

clothing

If possible, contain all runoff from decontamination

procedures for proper disposal.

Ensure that all potentially contaminated casualty

clothing and belongings have been removed and placed in properly labelled bags.

SUMMARY OF TREATMENT OF CASUALTIES

Assign highest priorities to Airway, Breathing,

Circulation (ABC) and then decontamination.

Complete primary and secondary assessments as

conditions allow.

Obtain information on chemicals to which the casualty

has been exposed from shipping papers, labels or other documents.

If there are multiple casualties, direct attention to

the most seriously affected individuals first.

Treat symptoms and signs as appropriate and when

conditions allow.

Obtain RADIO MEDICAL ADVICE when conditions allow.

Perform invasive procedures only in uncontaminated

areas.

Reassess the casualty frequently, because many

chemicals have latent physiological effects.

Delay preventive measures until the casualty is

decontaminated.

TRANSFER TO SHIP’S HOSPITAL

Casualties who have been stabilized (airway, breathing

and circulation) and decontaminated can be transported to the ship’s hospital

for further evaluation.

Further advice: see IMDG appendix 1

Packing

requirements as per the Dangerous Goods List of the IMDG Code

Structure of

the Dangerous Goods List.

The Dangerous Goods List is divided into 18 columns.

Among them the packing requirements are specified in

column 8 and in column 9

Column 8 Packing Instructions: This column contains

alpha – numeric codes, which refer to the relevant packing instructions. The

packing instructions indicate the packagings (including large packagings) which

may be used for the transport of substances and articles.

A code including the letter ‘P’ refers to packing

instructions for the use of packagings described in IMDG Chapters – 6.1, 6.2 or

6.3

A code including the letter ‘LP’ refers to packing

instructions for the use of large packagings described in IMDG Chapters – 6.6

A code including the letter ‘BP’ refers to the bulk

packagings described in IMDG Chapters – 4.3

When a code including the letters ‘P’, ‘LP’ or ‘BP’ is

not provided, it means that the substance is not allowed in that type of

packaging.

When ‘N/R’ is included in this column, it means that

the substance or article need not be packaged.

Column 9 Special packing provisions: This column

contains alphanumeric codes, which refer to the relevant special packing

provisions specified in 4.1.4. The special packing provisions indicate the

packagings (including large packagings).

A special packing provisions including the letters

‘PP’ refers to a special packing provision applicable to the use of a packing

instruction bearing the code ‘P’ in 4.1.4.1

A special packing provision including the letter ‘L’

refers to a special packing provision applicable to a packing instruction

bearing the code ‘LP’ in 4.1.4.3

Reporting

if the suitability and integrity of packages is found to be suspect

Documents

In all documents relating to the carriage of dangerous

goods by sea where the goods are named, the correct technical name of the goods

shall be used (trade names alone shall not be used) and the correct description

given in accordance with the classification.

The shipping documents prepared by the shipper shall

include, or be accompanied by, a signed certificate or declaration that the

shipment offered for carriage is properly packaged and marked, labelled or

placarded, as appropriate, and in proper condition for carriage.

The persons responsible for the packing of dangerous goods in a freight container or road vehicle shall provide a signed container packing certificate or vehicle packing declaration stating that the cargo in the unit has been properly packed and secured and that all applicable transport requirements have been met. Such a certificate or declaration may be combined with the document above.

Where there is due cause to suspect that a freight

container or road vehicle in which dangerous goods are packed is not in

compliance with the requirements, or where a container-packing certificate or

vehicle packing declaration is not available, the freight container or vehicle

shall not be accepted for shipment.

Each ship carrying dangerous goods shall have a

special list or manifest setting forth, in accordance with the classification,

the dangerous goods on board and the location thereof. A detailed stowage plan,

which identifies by class and sets out the location of all dangerous goods on

board, may be used in place of such a special list or manifest. A copy of one

of these documents shall be made available before departure to the person or

organization designated by the port State authority.

Cargo transport units, including freight containers,

shall be loaded, stowed and secured throughout the voyage in accordance with

the Cargo Securing Manual approved by the Administration. The Cargo Securing

Manual shall be drawn up to a standard at least equivalent to the guidelines

developed by the IMO.

The above are as per SOLAS. If the duty officer feels

that there is some discrepancy between the document submitted and the markings

on the cargo, he is to stop loading and inform the Master.

If the packaging is suspect or if the duty officer

feels that the packaging looks worn out or is not sufficient then again he is

to stop the loading and inform the Master.

General

fire precautions

The prevention of fire in a cargo of dangerous goods

is achieved by practicing good seamanship, observing in particular the following

precautions:

I.

keep combustible material away from ignition sources;

II.

protect a flammable substance by adequate packing;

III.

reject damaged or leaking packages;

IV.

stow packages protected from-accidental damage or

heating;

V.

segregate packages from substances liable to start or

spread fire;

VI.

where appropriate and practicable, stow dangerous

goods in an accessible position so that packages in the vicinity of a fire may

be protected;

VII.

enforce prohibition of smoking in dangerous areas and

display clearly recognizable “NO SMOKING” notices or signs; and

VIII.

the dangers from short-circuits, earth leakages or

sparking will be apparent. Lighting and

power cables, and fittings should be maintained in good condition. Cables or equipment found to be unsafe should

be disconnected. Where a bulkhead is

required to be suitable for segregation purposes, cables and conduit

penetrations of the decks and bulkheads should be sealed against the passage of

gas and vapours. When stowing dangerous

goods on deck, the position and design of auxiliary machinery, electrical

equipment and cable runs should be considered in order to avoid sources of

ignition.

Fire precautions applying to individual classes, and

where necessary to individual substances, are recommended in following

paragraphs and in the Dangerous Goods List.

Special

fire precautions for class 1

The greatest risk in the handling and transport of

goods of class 1 is that of fire from a source external to the goods, and it is

vital that any fire should be detected and extinguished before it can reach

such goods. Consequently, it is

essential that fire precautions, fire-fighting measures and equipment should be

of a high standard and ready for immediate application and use.

Compartments containing goods of class 1 and adjacent

cargo spaces should be provided with a fire detection system. If such spaces are not protected by a fixed

fire-extinguishing system, they should be accessible for fire-fighting

operations.

No repair work should be carried out in a compartment

containing goods of class 1. Special care should be exercised in carrying out

repairs in any adjacent space. No

welding, burning, cutting, or riveting operations involving the use of fire,

flame, spark, or arc-producing equipment should be carried out in any space

other than machinery spaces and workshops where fire-extinguishing arrangements

are available, except in any emergency and, if in port, with prior

authorization of the port authority,

Special

fire precautions for class 2

Effective ventilation should be provided to remove any

leakage of gas from within the cargo space or spaces, bearing in mind that some

gases are heavier than air and may accumulate in dangerous concentrations in

the lower part of the ship.

Measures should be taken to prevent leaking gases from

penetrating into any other part of the ship.

If there is any reason to suspect leakage of a gas,

entry into cargo spaces or other enclosed spaces should not be permitted until

the master or responsible officer has taken all safety considerations into

account and is satisfied that it is safe to do so. Emergency entry under other circumstances

should only be undertaken by trained crew wearing self-contained breathing

apparatus, and protective clothing when recommended, and always under the

supervision of a responsible officer.

Leakage from receptacles containing flammable gases

may give rise to explosive mixtures with air.

Such mixtures, if ignited, may result in explosion and fire.

Special

fire precautions for class 3

Flammable liquids give off flammable vapours which,

especially in an enclosed space, form explosive mixtures with air. Such vapours, if ignited, may cause a

“flashback” to the place in which the substances are stowed. Due regard should be paid to the provision of

adequate ventilation to prevent accumulation of vapours.

Special

fire precautions and fire fighting for class 7

The radioactive contents of Excepted, Industrial, and

Type A packages are so restricted that, in the event of an accident and damage

to the package, there is a high probability that any material released, or

shielding efficiency lost, would not give rise to such radiological hazard as

to hamper fire-fighting or rescue operations.

Type B (U) packages, Type B (M) packages and Type C

packages are designed to be strong enough to withstand severe fire without

significant loss of contents or dangerous loss of radiation shielding.

Precautions

while loading discharging explosives

Following are the emergency schedule1-01 with respect

to explosives under Class 1 Division 1.1

Primary hazard: Explosive substances and articles,

which may detonate all at once in a fire

Associated hazards: Heavy debris and high speed

fragments; possibility of the formation and escape of toxic fumes.

Special Emergency equipment to be available:

Protective clothing – gloves, fire resistant coveralls, fire mans helmet with

visors

SCBA

Non sparking footwear

Soft brushes and plastic trays – to pick up spillage

Emergency procedures:

Wear non sparking footwear when dealing with spillage.

Use SCBA and protective clothing when dealing with a spillage of materials

having a subsidiary class 6.1 and or 8 label. Avoid sources of ignition – naked

lights, unprotected light bulbs, electric hand tools, mechanical shock and

friction.

Use SCBA and protective clothing when dealing with fire.

Understanding the nature of the precautions that have

been laid down under the

Regarding whether water is to be kept available with a

charged hose, is debatable as far as the cargo is concerned – however the

likelihood of other non IMDG cargo catching fire does remain as such for the

other cargo the fire mains may be utilized.

Water if warranted by the IMDG code for the particular

cargo may be used else it should not be used unless shipper says it is OK to

use water or to cover spillage on deck with water.

Additionally fire extinguishers – CO2 systems should

be kept in readiness.

The ship generally loads this type of cargo last –

some ports have special anchorages or berths where such cargo is loaded, thus

it is necessary to have the ship ready to leave berth in case of any fire. As

such prior loading the ship should be ready to sail at a short notice.

Segregating of dangerous goods

Segregation

General

The provisions of this chapter should apply to all

cargo spaces on deck or under deck of all types of ships and to cargo transport

units.

The International Convention for the Safety of Life at

Sea (SOLAS), 1974, as amended, requires in regulation 6.1 of part A of chapter

VII that incompatible goods should be segregated from one another.

For the implementation of this requirement, two

substances or articles are considered mutually incompatible when their stowage

together may result in undue hazards in case of leakage or spillage, or any

other accident.

The extent of the hazard arising from possible

reactions between incompatible dangerous goods may vary and so the segregation

arrangements required should also vary as appropriate. Such segregation is obtained by maintaining

certain distances between incompatible dangerous goods or by requiring the

presence of one or more steel bulkheads or decks between them, or a combination

thereof. Intervening spaces between such

dangerous goods may be filled with other cargo compatible with the dangerous

substances in question.

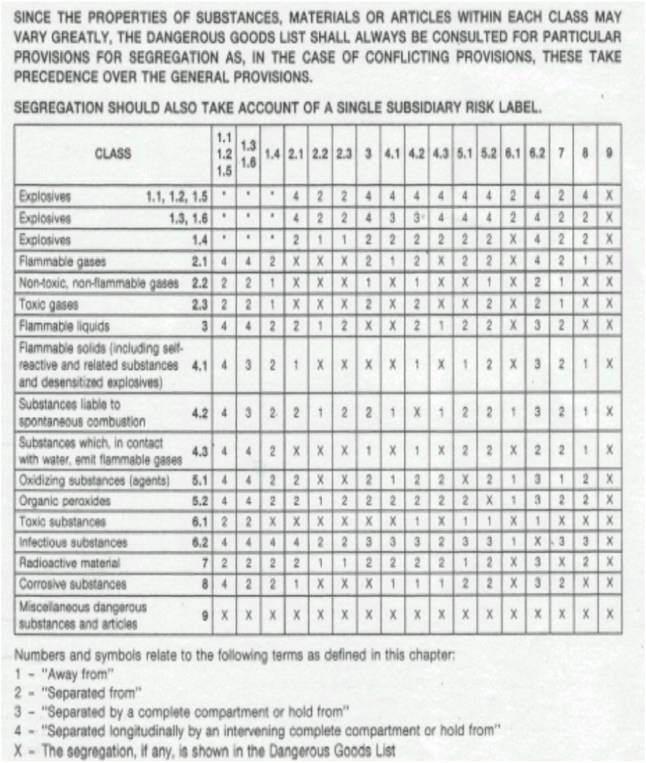

The following segregation terms are used throughout

this Code:

“Away from”;

“Separated from”;

“Separated by a complete compartment or hold from”;

“Separated longitudinally by an intervening complete

compartment or hold from”.

The general provisions for segregation between the

various classes of dangerous goods are shown in the

segregation table”.

In addition to the general provisions, there may be a

need to segregate a particular substance, material or article from other goods,

which could contribute to its hazard.

Particular provisions for segregation are indicated in the Dangerous

Goods List and, in the case of conflicting provisions, always take precedence

over the general provisions.

For example:

In the Dangerous Goods List entry for ACETYLENE,

DISSOLVED, class 2.1, UN 1001, the following particular segregation requirement

is specified:

“separated from” chlorine

In the Dangerous Goods List entry for BARIUM CYANIDE,

class 6.1, UN 1565, the following particular

segregation is specified:

“separated from” acids

Where the Code indicates a single secondary hazard

(one subsidiary risk label), the segregation provisions applicable to that

hazard should take precedence where they are more stringent than those of the

primary hazard.

Except for class 1, the segregation provisions for

substances, materials or articles having more than two hazards (2 or more

subsidiary risk labels) are given in the Dangerous Goods List.

In the Dangerous Goods List entry for BROMINE

CHLORIDE, class 2.3, UN 2901, subsidiary risks 5.1 and 8, the following

particular segregation is specified:

“segregation” as for class 5.1 but “separated from”

class 7”.

Segregation

of packages

Applicability

The provisions of this subsection apply to the

segregation of:

packages containing dangerous goods and stowed in the

conventional way;

dangerous goods within cargo transport units; and

dangerous goods stowed in the conventional way from

those packed in such cargo transport units.

Segregation of packages containing dangerous goods and

stowed in the conventional way

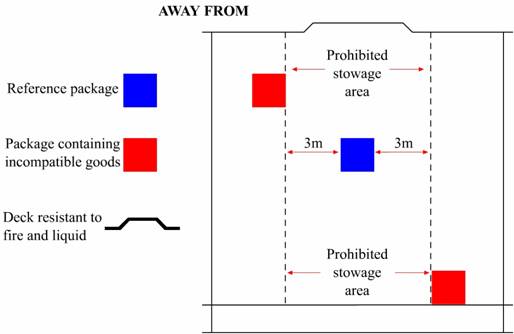

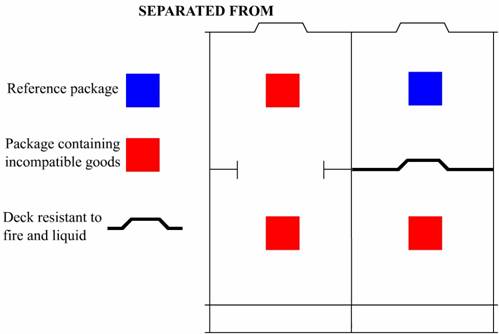

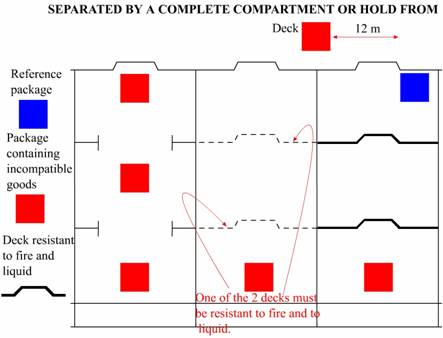

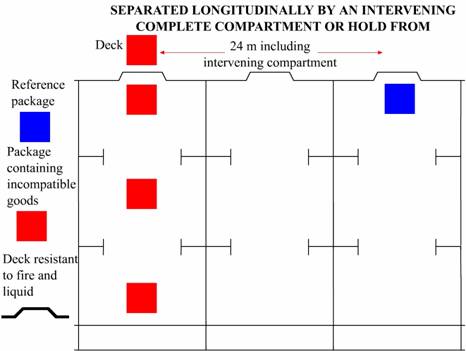

Definitions of the segregation terms Legend

Reference package - BLUE

Package containing incompatible goods - RED

Deck resistant to fire and liquid – BOLD LINE

NOTE. Full vertical lines represent transverse

bulkheads between cargo spaces (compartments or holds) resistant to fire and

liquid.

Away from:

Effectively segregated so that the incompatible goods

cannot interact dangerously in the event of an accident but may be transported

in the same compartment or hold or on deck, provided a minimum horizontal

separation of 3 metres, projected vertically, is obtained.

Separated

from:

In different compartments or holds when stowed under

deck. Provided the intervening deck is

resistant to fire and liquid, a vertical separation i.e. in different

compartments, may be accepted as equivalent to this segregation. For on deck stowage, this segregation means a

separation by a distance of sit least 6 metres horizontally.

Separated

by a complete compartment or hold from:

Either a vertical or a horizontal separation. If the

intervening decks are not resistant to fire and liquid, then only a longitudinal separation, i.e. by an intervening

complete compartment or hold, is acceptable. For on deck stowage, this

segregation means a separation by a distance of at least 12 metres

horizontally. The same distance has to be applied if one package is stowed on

deck and the other one in an upper compartment.

Note: One

of the two decks must be resistant to fire and to liquid.

Separated

longitudinally by an intervening complete compartment or hold from:

Vertical separation alone does not meet this

requirement. Between a package under deck and one on deck, a minimum distance

of 24 metres, including a complete compartment, must be maintained

longitudinally. For on deck stowage, this segregation means a separation by a

distance of at least 24 metres longitudinally.

Containment covered by the term “packaged form”

Chapter 4.1 describes the different types of packaging for use with goods under the IMDG code.

Definitions

Effectively

closed: liquid-tight closure.

Hermetically

sealed: vapour-tight closure.

Securely

closed: so closed that dry contents cannot escape during normal

handling; the minimum provisions for any closure.

General

provisions for the packing of dangerous goods, other than goods of classes 2, 6.2 or 7, in packagings, including Intermediate Bulk

Containers (IBCs) and large packagings

Dangerous goods should be packed in good quality

packagings, including IBCs and large packagings, which should be strong enough

to withstand the shocks and loadings normally encountered during transport,

including trans-shipment between cargo transport units and/or warehouses as

well as any removal from a pallet or overpack for subsequent manual or

mechanical handling. Packagings,

including IBCs and large packagings, should be constructed and closed so as to

prevent any loss of contents when prepared for transport, which might be caused

under normal conditions of transport, by vibration, or by changes in

temperature, humidity or pressure (resulting from altitude, for example). No dangerous residue should adhere to the

outside of packages, IBCs and large packagings during transport. These provisions apply, as appropriate, to

new, re-used, reconditioned or remanufactured packagings and to new and re-used

IBCs and large packagings.

Parts of packagings, including IBCs and large

packagings, which are in direct contact with dangerous goods:

.1 should not be affected or significantly weakened by

those dangerous goods; and

.2 should not cause a dangerous effect, such as

catalyzing a reaction or reacting with the dangerous goods.

Where necessary, they should be provided with a

suitable inner coating or treatment.

Unless provided elsewhere in this Code, each

packaging, including IBCs and large packagings, except inner packagings, should

conform to a design type successfully tested in accordance with the provisions

in the IMDG code.

When filling packagings, including IBCs and large

packagings, with liquids, sufficient

ullage (outage) should be left to ensure that neither leakage nor permanent

distortion of the packaging occurs as a result of an expansion of the liquid

caused by temperatures likely to occur during transport. Unless specific provisions are prescribed,

liquids should not completely fill a packaging at a temperature of

55˚C. However, sufficient ullage

should be left in an IBC to ensure that at the mean bulk temperature of

50˚C it is not filled to more than 98% of its water capacity.

Inner packagings should be packed in an outer

packaging in such a way that, under normal conditions of transport, they cannot

break, be punctured or leak their contents into the outer packaging. Inner packagings that are liable to break or

be punctured easily, such as those made of glass, porcelain or stoneware or of

certain plastics, materials, etc., should be secured in outer packagings with

suitable cushioning material. Any

leakage of the contents should not substantially impair the protective properties

of the cushioning material or of the outer packaging.

Cushioning and absorbent material should be inert and

suited to the nature of the contents.

The nature and the thickness of the outer packagings

should be such that friction during transport does not generate any heating

likely to alter dangerously the chemical stability of the contents.

Dangerous goods should not be packed together in the

same outer packaging, or in large packagings, with dangerous or other goods if

they react dangerously with each other and cause:

.1 combustion

and/or evolution of considerable heat;

.2 evolution

of flammable, toxic or asphyxiant gases;

.3 the

formation of corrosive substances; or

.4 the

formation of unstable substances.

Unless otherwise specified in the Dangerous Goods

List, packages containing substances should be hermetically sealed:

.1 evolve

flammable gases or vapour;

.2 may

become explosive if allowed to dry;

.3 evolve

toxic gases or vapour;

.4 evolve

corrosive gases or vapour; or

.5 may

react dangerously with the atmosphere.

Liquids may only be filled into inner packagings which

have an appropriate resistance to internal pressure that may be developed under

normal conditions of transport. Where

pressure may develop in a package by the emission of gas from the contents (as

a result of temperature increase or other cause), the packaging may be fitted

with a vent, provided that the gas emitted will not cause danger on account of

its toxicity, its flammability, the quantity released, etc. The vent should be so designed that, when the

packaging is in the attitude in which it is intended to be transported,

leakages of liquid and the penetration of foreign matter are prevented under

normal conditions of transport.

New, remanufactured or re-used packagings, including

IBCs and large packagings, or reconditioned packagings and repaired IBCs should

be capable of passing the tests prescribed in IMDG code. Before being filled and handed over for

transport, every packaging, including IBCs and large packagings, should be inspected

to ensure that it is free from corrosion, contamination or other damage and

every IBC should be inspected with regard to the proper functioning of any

service equipment. Any packaging which

shows signs of reduced strength as compared with the approved design type

should no longer be used or should be so reconditioned that it is able to

withstand the design type tests. Any IBC

which shows signs of reduced strength as compared with the tested design type

should no longer be used or should be so repaired that it is able to withstand

the design type tests.

Empty packagings, including IBCs and large packagings,

that have contained a dangerous substance should be treated in the same manner

as is required by this Code for a filled packaging, unless adequate measures

have been taken to nullify any hazard.

Every packaging, including IBCS, intended to contain

liquids should successfully undergo a suitable leak proofness test, and be

capable of meeting the appropriate test level indicated in IMDG code for the

various types of IBCs:

.1 before

it is first used for transport;

.2 after

remanufacturing or reconditioning of any packaging, before it is re-used for

transport;

.3 after the repair of any IBC, before it is re-used

for transport.

For this test, the packaging, or IBC, need not have

its closures fitted. The inner

receptacle of a composite packaging or IBC may be tested without the outer

packaging, provided the test results are not affected. This test is not necessary for inner

packagings of combination packagings or large packagings.

Packagings, including IBCS, used for solids which may

become liquid at temperatures likely to be encountered during transport should

also be capable of containing the substance in the liquid state.

Packagings, including IBCS, used for powdery or

granular substances should be sift-proof or should be provided with a liner.

Explosives,

self-reactive substances and organic peroxides

Unless specific provision to the contrary is made in

this Code, the packagings, including IBCs and large packagings, used for goods

of class 1, self-reactive substances of class 4.1 and organic peroxides of

class 5.2 should comply with the provisions for the medium danger group

(packing group 11).

Use of

salvage packagings

Damaged, defective or leaking packages or dangerous

goods that have spilled or leaked may be transported in special salvage

packagings. This does not prevent- the use of a bigger size of packagings of

appropriate type and performance level.

During transport, packagings, including IBCs and large

packagings, should be securely fastened to or contained within the cargo

transport unit, so that lateral or longitudinal movement or impact is prevented

and adequate external support is provided.

Additional

general provisions for the use of IBCs

When IBCs are used for the transport of liquids with a

flashpoint of 61˚C (closed cup) or lower, or of powders liable to dust

explosion, measures should be taken to prevent a dangerous electrostatic

discharge.

For rigid plastics IBCs and composite IBCs with

plastics inner receptacles, unless otherwise approved by the competent

authority, the period of use permitted for the transport of dangerous liquids

should be five years from the date of manufacture of the receptacle except

where a shorter period of use is prescribed because of the nature of the liquid

to be transported.

General

provisions concerning packing instructions

Packing instructions applicable to dangerous goods of

classes 1 to 9 are specified in chapter 4.1. They are subdivided in three

sub-sections depending on the type of packagings to which they apply:

sub-section 4.1.4.1 for packagings other than IBCs and

large packagings: these packing instructions are designated by an alphanumeric

code comprising the letter “P”;

sub-section 4.1.4.2 for

IBCS; these are designated by an alphanumeric code comprising the letters

“IBC”;

sub-section 4.1.4.3 for

large packagings; these are designated by an alphanumeric code comprising the

letters “LP”.

Special packing provisions may also be specified in

the packing instruction for individual substances or articles. They are also designated by an alphanumeric

code comprising the letters:

“PP” for

packagings other than IBCs and large packagings

“B” for

IBCs

“L” for

large packagings.

Column 8 of the Dangerous Goods List shows for each

article or substance the packing instructions) that should be used. Column 9 indicates the special packing

provisions applicable to specific substances or articles.

Each packing instruction shows, where applicable, the

acceptable single and combination packagings.

For combination packagings, the acceptable outer packagings, inner

packagings and, when applicable, the maximum quantity permitted in each inner

or outer packaging are shown. Maximum net mass and maximum capacity are as defined in chapter

1.2.1.

Where the packing instructions in this chapter

authorize the use of a particular type of outer packaging in a combination

packaging (such as 4G), packagings bearing the same packaging identification

code followed by the letters “V”, “U” or “W” marked in accordance with the

provisions of part 6 (such as “4GV”, “4GU” or “4GW”) may also be used under the

same conditions and limitations applicable to the use of that type of outer

packaging according to the relevant packing instructions. For example, a combination packaging marked

with the packaging code “4GV” may be used whenever a combination packaging

marked “4G” is authorized, provided the provisions in the relevant packing

instruction regarding types of inner packagings and quantity limitations are

respected.

The capacity of gas cylinders should not exceed 450

litres. The capacity for gas receptacles should not exceed 1000 litres.