| Grain Cargo | Cargo Care | IMDG | Cargo Handling Equipment | Cargo Handling Safety | |

| Oil Tanker | Cargo Measurement | Enclosed Spaces |

Cargo Work

Container Cargo

Sea Containers were invented in the mid

1950s by Malcolm McLean, a

The first ship modified to accept these “containers”

on deck, sailed with 58 of them from

The Matson Line (

The International Standards Organization (ISO) first

established container standards in 1961.

The ISO standard is not prescriptive and instead simply stipulates tests

that the containers must pass.

Modern container ships have only one problem – when

the ship arrives in port, the object is to unload the containers quickly to get

them on to their final destination and to get the container ships back out to

sea fully loaded heading for the next port.

To accomplish this, container ships are

equipped with steel skeletons called “cell guides”.

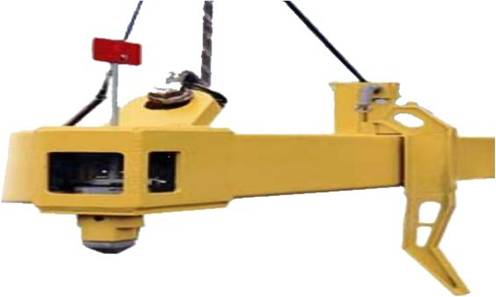

A special lifting fixture is used with

remote actuators, which engage the corner blocks on the top of the

container.

A recent survey indicates that port crane operators can execute full crane cycles to remove and position containers at rates of between 30 and 60 boxes per hour.

Containers come in two basic sizes – 20 Footer and 40

Footer and are commonly known as TEU (Twenty Equivalent Units) and FEU (Forty

Equivalent Units).

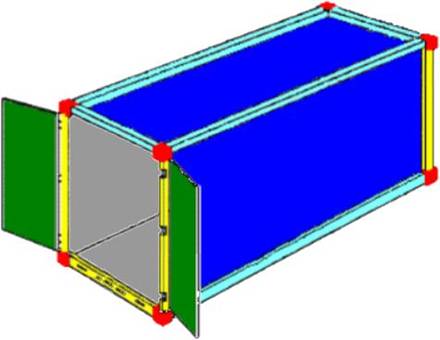

The external body of the container is made of

corrugated sheet metal and is not capable of taking any load. The four corners

have shoes and are strengthened to take in load.

The inside bottom has a wooden ceiling. There are

weather-insulted vents provided to facilitate venting.

The weights marked on the containers are TARE weight

and LADEN weight. TARE weight is the weight of the empty container and is

usually 2200KGS for a TEU, while the LADEN weight may be anything from 20000KGS

to 32000KGS (strengthened steel construction).

The container shoes fitted at the corners are hollow with 5 oval slots to facilitate the fitting of container fittings as well as for lifting the container – either by using conventional wire slings or by spreaders.

Since the containers are concentrated weights the

loading of the same require special heavy dunnaging to spread the load evenly

over the deck – if carried as deck cargo on conventional general cargo ships.

However the carriage of containers are primarily on

container ships or on ships, which have been built to take in general cargo as

well as containers to a limited extent.

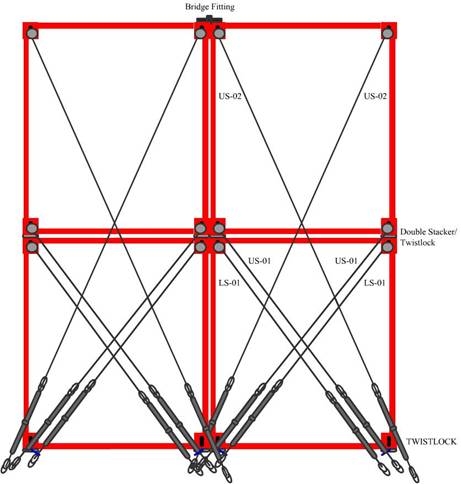

Lashing of containers on purpose ships are supplied

from reputed lashing makers and have been tested for the loads they are to

lash. Various fittings are used and all of these are generally carried on

board.

Base stacker Twist

Lock Double

Stacker

Corner Eye Pad Side

Stack Thrust Bridge

Fitting

Twist Lock Rod

Lashing Bar Spacer

Stacker

A spacer stacker is used where there is a difference

between adjacent containers as loaded in their heights, one being the 8ft and

the other 8.5FT.

On normal ships where these fittings may not be

available wire ropes are used however the number of ropes to be used would be

decided by the weight of the container.

On GC ships with no provision for built in shoes only

single height loads are carried.

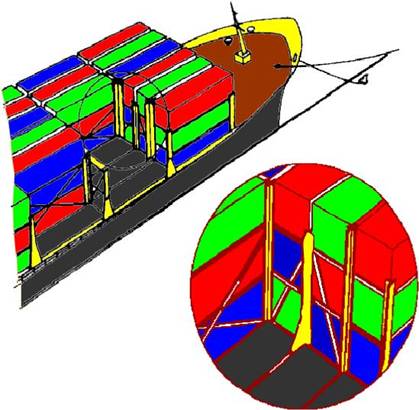

However on container ships the hold stacks may extend

to 7 high and on hatch top/ deck to 5 high.

The hold and the deck/ hatch top being strengthened.

The lashings to be done are specified in the

container-lashing manual supplied to the ship from the building yard. This is

not to be reduced since the stresses have been calculated and the number of

lashings incorporated.

The containers are loaded onto a container ship in a

specified manner. The ship is divided into BAYS or ROWS. Looking from the side

the bays are marked from forward to aft.

The containers are stacked in tiers and are in general

called the stacks.

This way ensures that any container can be located

very easily – knowing the bay number and the row number isolates the location

and the stack height give the exact position of the container.

On container ships the containers are lowered onto

slots inside the holds, the holds bottom is provided with sunken shoes, twist

locks/ stackers are fitted onto these and the container is lowered onto them.

Cell Guides

on Deck – Open hatch concept:

Some containers are designed to carry refrigerated

cargo, these special containers have their own cooling plant in built on one

end of the container, and all that is required for the ship to provide is a

power point for the electricity. The containers come with their own recording

device and card, the ships officers has to renew the card on the expiry of the

same, and is to see that the cooling plant does not stop functioning, manuals

are provided whereby ships staff can do some minor repairs to the plant.

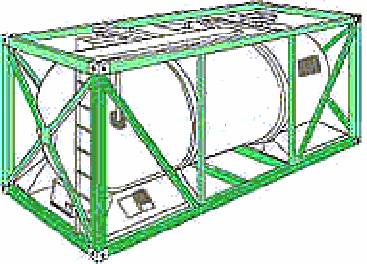

Today a variety of cargo which previously was thought

could only be loaded onto a general cargo ship, is transported on container

ships. An example is a tank, thus small parcels of liquid is carried on container

ships.

Lashing of containers is very important since a

typical container ship has a low GM(F), consequently the ship rolls quite a bit

and the stresses developed by the cargo swaying is liable to break the lashings

and put the containers into the sea.

All lashings are to be done following the ships lashing manual. In general the following is a typical lashing system, others may also be accepted if permitted by the manual.

The planning of loading of a container ship is

normally undertaken ashore, but the officer in charge of the watch should keep

an eye on the loading to detect errors in stowage which may occur. A particular

watch should be kept for containers with dangerous goods placards to see that

their stowage satisfies segregation requirements as laid down in the IMDG code.

Other things to watch for are that container marked

for underdeck stowage do not end up on deck – this is serious since the

container may be for second port by rotation, also the heavier containers are

generally loaded underdeck to increase the GM. Thus in addition to a loss of GM

the ship would also have a mess up at the disport.

Refrigerated containers should be loaded where they

can be connected to the ship’s power supply and the duty officer is to ensure

the same. While loading a slight slackening of watch can become a liability

since the gantries load very fast and to unload or to shift is expensive and

time consuming – even if the fault actually is of the port.

Sometimes containers are loaded which due to the

nature of the contents have to be overstowed, in this case the container is

loaded and the container is then blocked off so that there would be no chance

of any pilferage – such containers may carry – currency/ coins, drugs, and mail

or other high value cargo.