| Grain Cargo | Cargo Care | IMDG | Cargo Handling Equipment | Cargo Handling Safety | |

| Oil Tanker | Cargo Measurement | Enclosed Spaces |

Cargo Work

Oil Tanker

A tanker is a specialized ship intended for the carriage of bulk liquid cargo. An Oil tanker again is further divided into 2 basic types, namely Crude Oil Tanker and Product Oil Tanker.

For both of the above the cargo of oil is carried

within the tanks similar to the holds of other ships, the difference being that

the bulkheads are extra strengthened to take in the load, and the hatch or

rather the tank openings are very small, the sole purpose of having them is for

Man Entry and for small repair work in the dry docks.

The cargo of oil is loaded on to the ships tanks by

pipelines, which are fixed on the ship (permanent structure), the shore

pipelines are connected to the ships pipelines at the manifold on either side

of the ship. Note that some special ships also have manifolds at the bow and at

the stern.

The shore pipelines may be connected using flexible

steel rimmed rubber hoses (small ports/ Ship to ship transfers/ SBM) – the

flexible come in small lengths are connected to each other to make them long

pieces.

The shore pipelines may also be connected with rigid

loading arms – also called ‘chiksons’, which are remotely controlled and take

in the roll of the ship to a certain extent but the fore and aft movement of

the ship has to be kept to a minimum.

The combined pipeline system of the shore and the ship

deliver the oil to the cargo oil tanks directly via the drop lines. These are

as the name suggests pipelines, which drop to the bottom of the tanks

vertically from the pipeline on deck – thus bypassing the pump room.

There are various cross- over valves, which are opened

in order to load a group of tanks.

The shore system starts to pump/ delivers by gravity

(some

To prevent this surge from affecting the pipelines the

cargo valves have set times at which they close – this depends on the size of

the valves – typically a 550mm valve would shut at about 24 seconds, whereas a

250mm valve would shut at 6-8 seconds.

After the ship completes her loading the stage is set

for the unloading or discharging operation.

While loading the cargo had by passed the pump room,

now however the cargo from the tanks is allowed to flow to the pump room

through the bottom pipelines. Just within the pumproom and at the pumproom

bulkhead are situated isolation valves known as ‘Bulkhead Master valves’, by

opening the valves the oil is led to the pump suction valve and on opening that

the oil flows to the centrifugal pumps. Turbines, which are situated in the

Engine Room, commonly drive these pumps; the shaft penetrates the ER bulkhead

and drives the pump situated at the bottom of the pumproom.

The pump accelerates the flow of the oil into the

discharge pipeline and this oil is thus led on the deck pipelines and to the

manifold from where it flow through the flexible pipeline or the hard loading arm

to the shore pipeline system.

The Pump Room

This is a cofferdam kind of space – in fact it is

accepted as a cofferdam, which begins on main deck and ends at the keel.

It may have more than 2 decks, however these decks are

not normally solid decks but are partial decks made of expanded metal, so you

are able to see right to the bottom.

There would be a companionway leading from the top to

the next deck and so on right to the bottom.

At the lowermost deck are situated the Cargo Oil Pumps

(COP’s). The numbers of pumps vary in number – for crude oil tankers it is

normal to have 4 pumps, three being used at any one time.

For product oil tankers the number of pumps depend on

the number of grade of oil that the ship is capable of carrying.

So if the ship can carry 4 grades of oil then she

would be having 4 pumps.

Once the gravity flow to the COP’s is not possible the

stripped pumps are started, these pumps are of the reciprocating type and have

great capacity to create partial vacuum to suck out the remaining oil from the

tanks. Again on a product oil tanker the number of stripped pumps would be

equal to the number of grades of oil that it can carry.

Earlier on Crude oil carrier there would be stripper

pumps of the reciprocating type however today largely eductors are used to

remove the remaining oil from the tank. Generally 2 eductors are provided on

each crude oil tanker. However 1 stripper pump is always provided to strip the

cargo lines of any residual oil and to pump the same to the shore system.

The pumproom is a hazardous area as such the light

fittings are gas tight and only tanker safety torches are used. The ventilation

system is of the exhaust type and has intakes from all the levels with the

intakes being fitted with closing devices so that if required only a certain

level can be evacuated.

Hydrocarbon gases being heavier than air tend to

settle at the bottom of the pumproom as such the main exhaust are always from

the bottom level.

The pumproom lighting is devised in such a way that

the lights do not come on unless the ventilation has been started and is kept

on for 15 minutes.

AT the top of the pumproom a harness and lifting

arrangement is provided to lift out a person from the lowermost deck, for this

reason a clear passage is left vertically from the top to the bottom of the

pumproom.

Fire man’s outfit are also placed at the top of the

pumproom, the pumproom may have different types of fixed fire fighting

appliances such as total flooding by CO2 or by foam applicators fitted in the

bilges (below the floor plates under the lowermost deck).

Bilge alarms are fitted which give alarms when the

bilges are filled – a high level and a low level alarm is fitted which gives

indications in the Engine room as well as in the Cargo Control room.

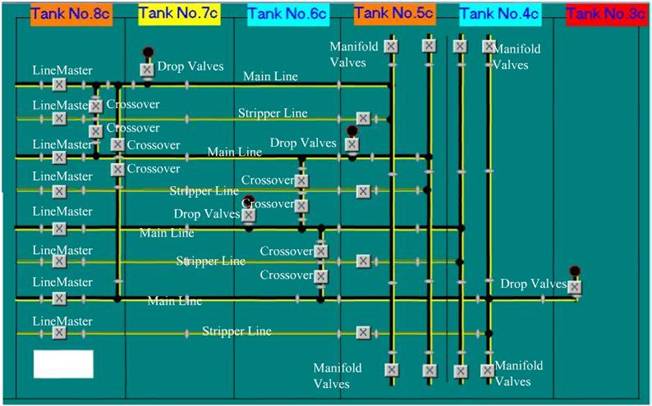

Picture shows the main deck layout of a Product tanker

(capable of carrying 4 grades of oil):

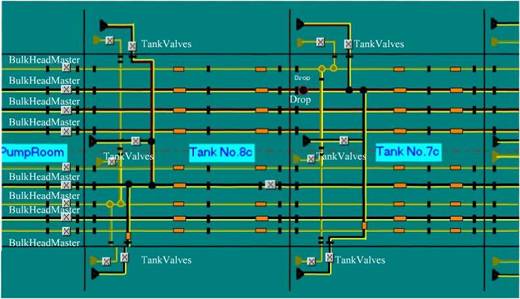

The same

tanker – with the tank layout.

And part of the pump room layout of the same tanker.

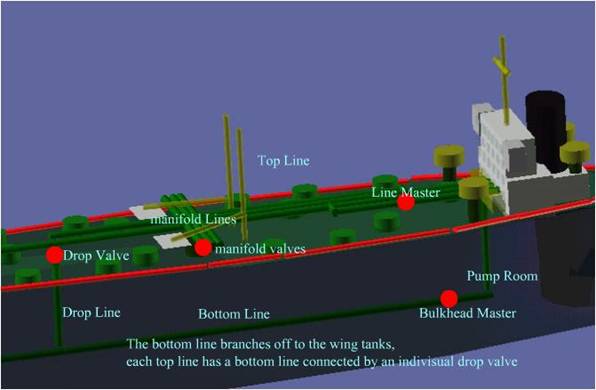

The above shows the location of the drop valves; drop

lines, line master, bulkhead master and the bottom lines.

Cargo Oil

Pumps (COP)

A centrifugal pump, in the pumproom bottom platform.

The dark green pipeline is the discharge line. The pump consists of an impeller

which rotates within the casing. Due to this rotation which is generally about

1000 – 1700 rpm the oil is speeded up and this increase in velocity causes the

oil to flow out at a great pressure. These pumps are capable of delivering a

very high rate of discharge (up to 4000 m3/hr). With this type of pump the

level of oil has to be above the pump – as such the pump is situated at the

bottom of the pump room.

Another detail of the same centrifugal pump.

The earlier centrifugal

pump situated in the pumproom is driven by a shaft which is connected to the

steam turbine – situated in the ER. The shaft passes from the ER to the

pumproom through the pumproom bulkhead via a gas and oil tight gasket.

The turbines are driven

by superheated steam from the boiler in the ER.

Positive displacement

pumps such as the reciprocating pump work on the principle of a hand pump – the

movement of the piston creates a vacuum which sucks out the fluid. However the

size of the pump is dependent on the size of the piston and the length of the

strokes so for discharging at a high rate is practically impossible. In general

these pumps are used to discharge small quantities of oil such as the

strippings – the balance that the centrifugal pump cannot discharge due to the

oil going below the level of the pump. The pump is used today on crude tankers to

strip out the pipelines after discharging and then collecting these line

content (small) and then pumping them to shore.

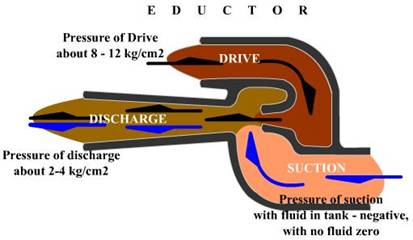

Eductors

Eductors work on the

principles of Bernoulli’s Principle.

A driving fluid is

pumped down the main line, with very high velocity, through a constriction, and

past a relatively smaller opening, thus creating a vacuum.

When eductors are used

for clean ballast, the driving fluid is seawater.

When used for stripping

crude oil, the driving fluid is the cargo itself- delivered by means of a

bypass from one of the main cargo pumps.

When used for stripping

tank washings, the driving fluid is from the secondary slop tank and then

re-circulated back to the primary slop tank. In the latter case the driving

fluid is either crude oil or seawater, depending on the tank cleaning method.

Eductors are simple and rugged, have no moving

parts, and do not become air locked like other type of pumps. They are widely

used on tankers of all types and sizes.

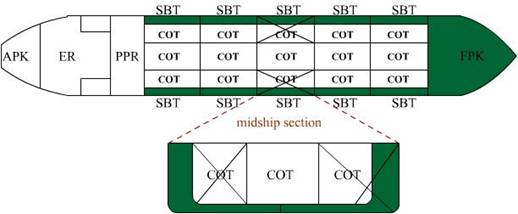

Tank layout

of a crude oil tanker:

The Pipeline system:

Pipeline systems on

tankers differ in their degree of sophistication, depending on employment of

the tanker.

ULCC’s and VLCC’s have

relatively simple pipeline systems usually the direct line system.

Some product (parcel)

tankers may have very sophisticated piping systems. This could be the ring main

system or in case of a chemical product tanker it could mean an individual

pipeline and an individual pump for every tank on board.

Basically there are

three systems of pipelines found on tankers, and the fourth system being the

free flow system found on large crude carriers

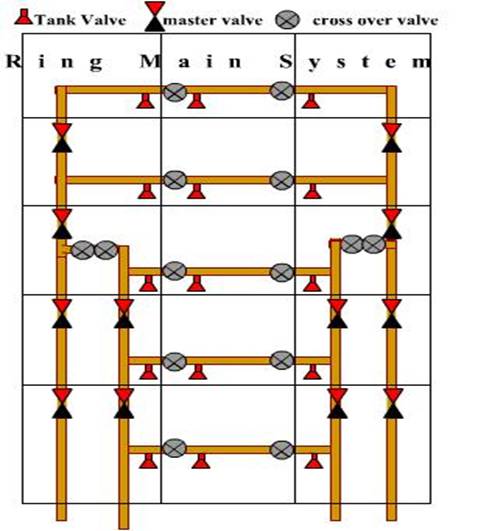

Ring Main System

Direct line system

Single line to Single

tank system (Chemical/Product ship)

Free Flow system

Ring Main System:

It is generally of a

square or circular layout.

It is used mostly on

product tankers, as segregation of cargo is required.

Though the system is

expensive, as more piping, and extra number valves are used.

However if the vessel is

carrying many grades of cargo, the advantages compensate for the extra cost of

the original outlay.

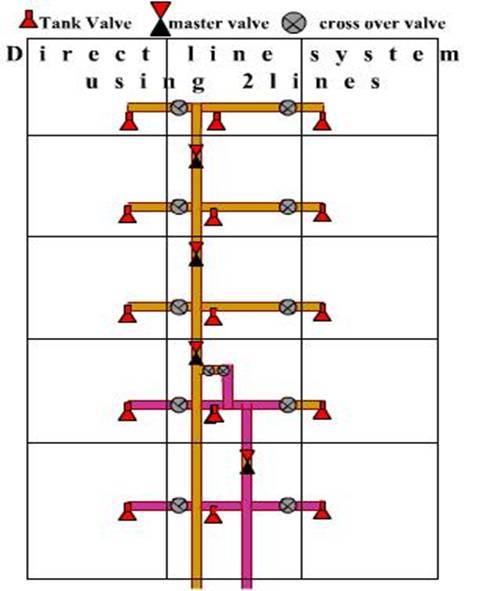

Direct Line

System:

This system is mainly found on crude oil carriers

where up to 3 grades of cargo can be carried as most of the direct pipeline

systems is fitted with three direct lines.

This system is cheaper to construct. The disadvantages

over the ring main system, is that line washing is more difficult, the system

has fewer valves which make pipeline leaks difficult to control, as the system

lacks versatility there is problem with line and valve segregation.

This system provides the

vessel to carry as many grades as there are tanks.

The

disadvantage is the cost factor having a multitude of pumps on board.

Free flow Tanker:

This system is usually

found on large crude carriers, where the cargo piping is not used for the

discharge of cargo.

Instead, gate valves are

provided on the bulkheads of the tanks which when opened; allow the oil to flow

freely in the aft most tank and into the COP.

The advantages of this

system are primarily the cost factor, it allows for fast drainage and efficient

means of pumping the cargo tanks. Disadvantages are of single crude being

shipped.

Independent System:

This layout is not very

common in the tanker trade.

This system is quite

normal on chemical ships.

There are some Product

Tankers that have this system fitted on the ships.

This is a single line

servicing an individual tank through an independent pump that could be either a

submersible pump or a deep well pump.

Enclosed

Space Entry

An enclosed space is one with restricted access that

is not subject to continuous ventilation and in which the atmosphere may be

hazardous due to the presence of hydrocarbon gas, toxic gases, inert gas or

oxygen deficiency. This definition includes cargo tanks, ballast tanks, fuel

tanks, water tanks, lubricating oil tanks, slop and waste oil tanks, sewage

tanks, cofferdams, duct keels, void spaces and trunkings, pipelines or fittings

connected to any of these. It also includes inert gas scrubbers and water seals

and any other item of machinery or equipment that is not routinely ventilated

and entered, such as boilers and main engine crankcases.

Many of the fatalities in enclosed spaces on oil

tankers have resulted from entering the space without proper supervision or

adherence to agreed procedures. In almost every case the fatality would have

been avoided if the simple guidance in this chapter had been followed. The

rapid rescue of personnel who have collapsed in an enclosed space presents

particular risk. It is a human reaction to go to the aid of a colleague in

difficulties, but far too many additional and unnecessary deaths have occurred

from impulsive and ill-prepared rescue attempts.

Respiratory hazards from a number of sources could be

present in an enclosed space. These could include one or more of the following:

Respiratory contaminants associated with organic

vapours including those from aromatic hydrocarbons, benzene, toluene, etc.;

gases such as hydrogen sulphide; residues from inert gas and particulates such

as those from asbestos, welding operations and paint mists.

Oxygen deficiency caused by, for example, oxidation

(rusting) of bare steel surfaces, the presence of inert gas or microbial

activity.

Hydrocarbon Vapours

During the carriage and after the discharge of hydrocarbons,

the presence of hydrocarbon vapour should always be suspected in enclosed

spaces for the following reasons:

Cargo may have leaked into compartments, including

pumprooms, cofferdams, permanent ballast tanks and tanks adjacent to those that

have carried cargo.

Cargo residues may remain on the internal surfaces of

tanks, even after cleaning and ventilation.

Sludge and scale in a tank which has been declared gas

free may give off further hydrocarbon vapour if disturbed or subjected to a

rise in temperature.

Residues may remain in cargo or ballast pipelines and

pumps.

The presence of gas should also be suspected in empty

tanks or compartments if non-volatile cargoes have been loaded into non-gas

free tanks or if there is a common ventilation system which could allow the

free passage of vapours from one tank to another.

Oxygen

Deficiency

Lack of oxygen should always be suspected in all

enclosed spaces, particularly if they have contained water, have been subjected

to damp or humid conditions, have contained inert gas or are adjacent to, or

connected with, other inerted tanks.

Other

Atmospheric Hazards

These include toxic contaminants such as benzene or

hydrogen sulphide, which could remain in the space as residues from previous

cargoes.

ATMOSPHERE

TESTS PRIOR TO ENTRY

General

Any decision to enter an enclosed space should only be taken after the atmosphere within the space has been comprehensively tested from outside the space with test equipment that has recently been calibrated and checked for correct operation.

It is essential that all atmosphere testing equipment

used is:

Suitable for the test required;

Of an approved type;

Correctly maintained;

Frequently checked against standard samples.

A record should be kept of all maintenance work and

calibration tests carried out and of the period of their validity. Testing

should only be carried out by personnel who have been trained in the use of the

equipment and who are competent to interpret the results correctly.

Care should be taken to obtain a representative

cross-section of the compartment by sampling at several depths and through as

many deck openings as practicable. When tests are being carried out from deck

level, ventilation should be stopped and a minimum period of about 10 minutes

should be allowed to elapse before readings are taken.

Even when tests have shown a tank or compartment to be

safe for entry, pockets of gas should always be suspected. Hence, when

descending to the lower part of a tank or compartment, further atmosphere tests

should be made. Regeneration of hydrocarbon gas should always be considered

possible, even after loose scale has been removed. The use of personal

detectors capable of continuously monitoring the oxygen content of the

atmosphere, the presence of hydrocarbon vapour and, if appropriate, toxic

vapour is strongly recommended. These instruments will detect any deterioration

in the quality of the atmosphere and can provide an audible alarm to warn of

the change in conditions.

While personnel remain in a tank or compartment,

ventilation should be continuous and frequent atmosphere tests should be

undertaken. In particular, tests should always be made before each daily

commencement of work or after any interruption or break in the work.

Sufficient samples should be drawn to ensure that the

resulting readings are representative of the condition of the entire space.

Hydrocarbon Vapours

To be considered safe for entry, whether for

inspection, cold work or hot work, a reading of not more than 1% LFL must be

obtained on suitable monitoring equipment.

Benzene

Checks for benzene vapour should be made prior to

entering any compartment in which a cargo that may have contained benzene has

recently been carried. Entry should not be permitted without appropriate

personal protective equipment if statutory or recommended Permissible Exposure

Limits (PEL’s) are likely to be exceeded. Tests for benzene vapours can only be

undertaken using appropriate detector equipment, such as that utilizing

detector tubes. (Benzene causes cancer, and has a delayed action which may be

up to 20years)

Detector equipment should be provided on board all

vessels likely to carry cargoes in which benzene may be present.

Hydrogen

Sulphide

Although a tank which has contained sour crude or sour

products will contain hydrogen sulphide, general practice and experience

indicates that, if the tank is thoroughly washed, the hydrogen sulphide should

be eliminated. However, the atmosphere should be checked for hydrogen sulphide

content prior to entry and entry should be prohibited in the event of any

hydrogen sulphide being detected. Hydrogen sulphide may also be encountered in

pumprooms and appropriate precautions should therefore be taken.

Oxygen Deficiency

Before initial entry is allowed into any enclosed

space, which is not in daily use, the atmosphere should be tested with an

oxygen analyzer to check that the normal oxygen level in air of 21% by volume

is present. This is of particular importance when considering entry into any

space, tank or compartment that has previously been inerted.

Generally

nearly all substances have been assigned Permissible Exposure Limits (PEL) and

/or Threshold Limit Values (TLVs). The term Threshold Limit Value (TLV) is

often expressed as a time weighted Average (TWA). The use of

the term Permissible Exposure Limit refers to the maximum exposure to a toxic

substance that is allowed by an appropriate regulatory body.

The PEL is

usually expressed as a Time Weighted Average, normally averaged over an eight-hour period.

Short Term

Exposure Limit (STEL), is normally expressed as a maximum airborne

concentration averaged over a 15-minute period.

The values

are expressed as parts per million (PPM) by volume of gas in air. Toxicity can

be greatly influenced by the presence of some minor components such as aromatic

hydrocarbons (e.g. benzene) and hydrogen sulphide. A TLV of 300PPM,

corresponding to about 2%LEL, is established for gasoline vapours.

Entry Procedures

General

A responsible officer prior to personnel entering an

enclosed space should issue an entry permit. An example of an Enclosed Space

Entry Permit is provided in ISGOTT.

Suitable notices should be prominently displayed to

inform personnel of the precautions to be taken when entering tanks or other

enclosed spaces and of any restrictions placed upon the work permitted therein.

The entry permit should be rendered invalid if

ventilation of the space stops or if any of the conditions noted in the

checklist change.

No one should enter any cargo tank, cofferdam, double

bottom or other enclosed space unless an entry permit has been issued by a

responsible officer who has ascertained immediately before entry that the

atmosphere within the space is in all respects safe for entry. Before issuing

an entry permit, the responsible officer should ensure that:

The appropriate atmosphere checks have been carried

out, namely oxygen content is 21% by volume, hydrocarbon vapour concentration

is not more than 1% LFL and no toxic or other contaminants are present.

Effective ventilation will be maintained continuously

while the enclosed space is occupied.

Lifelines and harnesses are ready for immediate use at

the entrance to the space.

Approved positive pressure breathing apparatus and

resuscitation equipment are ready for use at the entrance to the space.

Where possible, a separate means of access is

available for use as an alternative means of escape in an emergency.

A responsible member of the crew is in constant

attendance outside the enclosed space in the immediate vicinity of the entrance

and in direct contact with a responsible officer. The lines of communications

for dealing with emergencies should be clearly established and understood by

all concerned.

In the event of an emergency, under no circumstances

should the attending crew member enter the tank before help has arrived and the

situation has been evaluated to ensure the safety of those entering the tank to

undertake rescue operations.

Regular atmosphere checks should be carried out all

the time personnel are within the space and a full range of tests should be

undertaken prior to re-entry into the tank after any break.

The use of personal detectors and carriage of

emergency escape breathing apparatus are recommended.

Reference should be made to ISGOTT for additional

guidance on entry into pumprooms.