| Grain Cargo | Cargo Care | IMDG | Cargo Handling Equipment | Cargo Handling Safety | |

| Oil Tanker | Cargo Measurement | Enclosed Spaces |

Cargo Work

Cargo Handling Equipment

Care and Maintenance of Steel Wire Rope

Wire ropes have a lubricant incorporated during manufacture. This serves a dual purpose; it provides corrosion protection and also minimises internal friction. The protection provided by this manufacturing lubricant is normally adequate to prevent deterioration due, to corrosion during the early part of a rope’s life. However, the lubricant applied during manufacture must be supplemented by lubrication in service. This service lubricant is termed the ‘dressing’ the kind of dressing used and the frequency of application varies with the type of rope and its usage. Details of the maintenance of steel wire rope carried, or fitted in, ships is laid down in the Maintenance Manual of the Company or the Planned Maintenance Schedule (PMS) of the item. Wire hawsers should be stowed on reels under a fitted cover whenever possible. When being reeled in or otherwise stowed, the surface of a wire hawser should be washed with fresh water to free it from salt, then dried with cloths and lightly smeared with the appropriate lubricant.

Inspecting Steel Wire Rope

Steel wire ropes carried or fitted in ships must be

inspected periodically in accordance with the PMS. When inspecting, the indications described

below should be sought:

Distortion

of Strands: This is the

result of damage by kinking, crushing, serious crippling round a bad nip, or

other mistreatment. If likely to cause

the strands to bear unequal stresses they must be considered as reducing the

strength of the rope by 30%; and should they be sufficiently serious to cause

the heart to protrude, the rope must be discarded. A crushed rope may be restored to some extent

by the careful use of a mallet.

Flattening

of Some of the Outer Wires by Abrasion: These

flat’s are easily seen because the abrasion gives the flattened wires a bright

and polished appearance, but they do not affect the strength of the rope unless

they are very pronounced. Flats, which

extend to three-quarters of the diameter of the wires will reduce their

cross-sections - and therefore their individual strengths - by 10%, and as only

a limited number of wires will be affected the loss in strength of the whole

rope will be very small. (These flats must not be confused with flattening of

the whole rope, which indicates distortion of the strands and is therefore much

more serious).

Broken

Wires: These are usually the result of fatigue and wear, and mostly

occur in crane wires. It is generally

accepted that a wire rope is coming to the end of its useful life when one wire

of any strand breaks. To deal with a

broken wire, grip with a pair of pliers the broken end and bend the wire

backwards and forwards until the wire breaks inside the rope between the

strands, where it can do no harm. A rope

should be discarded if more than 5% of its wires are broken in a length equal

to 10 times the diameter of the rope; for example a 24mm diameter, 6X24 wire

rope should be discarded if seven broken wires are found in a length of

240mm. Because of the danger to

handlers, berthing wires should be discarded if any broken wires are

discovered.

Corrosion:

Wire rope can be corroded by:

The action of damp on the wires from which the

gaivanising has worn off, if this occurs to the inner wires first it causes

rust to fall out of the rope and is therefore easily detected;

The action of fumes and funnel gases, which attack the

outside wires, the effect then becomes visible on inspection;

Contact with acid, which soaks into the heart and

attacks the inside wires; this is not necessarily noticeable on the outside of

the rope, and can be the cause of parting without warning.

Lack of lubrication is a frequent cause of

corrosion. When a wire rope is under

tension it stretches and becomes thinner, and during this process the

individual wires are compressed and friction is set up; the fibre heart and

cores are also compressed, releasing oil to overcome the friction. A wire rope of outwardly good appearance, but

with a dry powdery heart or core, has -not been properly maintained and should

be treated with caution.

Effect of

Extreme Cold:

When subjected to extreme cold a wire rope may become

brittle and lose its flexibility, and an apparently sound rope may part without

warning. The brittleness is not permanent

and the rope will regain its resilience in a normal temperature, but the

potential danger should be remembered when working wires in very cold climates.

Testing of

Steel Wire Rope

The wire from which the rope is to be made is tested

before manufacture of the rope to ensure it complies with the relevant

Standards with regard to tensile strength, torsion and galvanising

properties. After manufacture of each

production length of rope, test samples are cut from the finished rope and

strand. These samples are used for a

tensile test to destruction, tests of preforming of the rope, and tests on a

mixture of the individual wires with regard to diameter, tensile strength,

torsion and quality of galvanising. Each

coil of wire is accompanied by a certificate of conformity and a test

certificate showing the guaranteed minimum breaking strength of the wire. (WHEN NEW.)

General

Remarks on Steel Wire Rope

How to

Measure the Size of a Rope

The size of a wire rope is the diameter in millimetres

of a true circle, which will just enclose all the strands. Measure at each of three places at least 2m

apart. The average of these measurements

is to be taken as the diameter of the rope.

Sheaves for

Wire Rope

Size of Sheave Required for a Wire Rope Hoist. The diameter of sheave required for

each type of six-strand wire rope supplied should be at least twenty times the

diameter of the wire. The diameter of a

sheave used for any wire rope will considerably affect the life of that rope. As the rope bends round a sheave the strands

and wires farthest from the centre of curvature move apart and those nearest

the centre of curvature move closer together.

This results in the generation of considerable friction between these

wires and strands, and the smaller the sheave the greater will be the

friction. Friction also increases

rapidly with the speed at which the rope is moving. While the rope is bent round a sheave the

outer wires are also subjected to a marked additional stress, and the smaller

the diameter of the sheave the greater will be the stress. For these reasons the minimum diameters of

sheaves recommended from practical experience for various types of ropes at

speeds not exceeding 60m per minute are 20 times the diameters of the ropes. For each increase in speed of 30m per minute,

5% must be added to these figures; this will give a rope a reasonable life, but

it is emphasized that its life will be greatly increased if still larger

sheaves are used. Similarly, if a

smaller sheave than that recommended has to be accepted it will shorten the

life of the rope, and on no account should a sheave be used that is more than

20% smaller than that determined by reference to the above criteria.

Use of

Correct Sheave:

The life of a rope used for

hoisting can also be considerably shortened by using the wrong type of

sheave. The groove in the sheave must

fit and support the rope as it travels round the sheave, otherwise there will

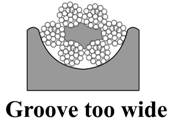

be increased internal friction and external wear. Figure below shows a sheave with too wide a

groove, which results in a flattening of the rope and considerable distortion

and internal friction.

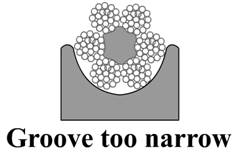

Figure below shows a sheave with too narrow a groove,

which results in the rope not being supported, the wires of the strands being

subjected to considerable wear, and friction being set up between the rope and

the sides of the groove.

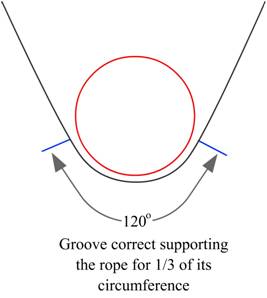

The groove of the correct sheave should be shaped in

cross-section to the true arc of a circle for a distance equal to one-third of

the circumference of the rope, and the radius of the groove should be between 5

and 10% greater than the specified radius of the rope.

Cargo Blocks

Rigging of

cargo blocks:

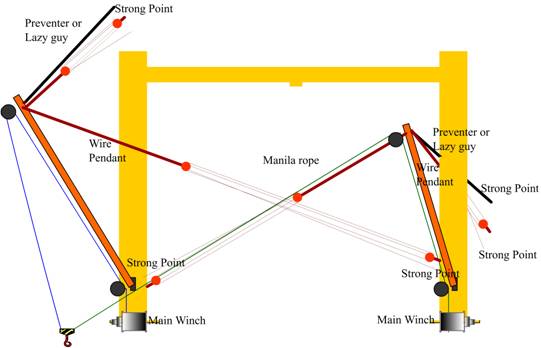

Union

Purchase – derricks with 2 sets of individual side guys.

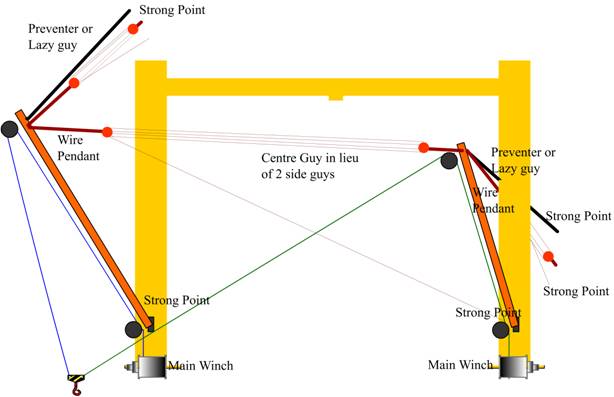

Union

Purchase – derricks with 1 set of individual side guys and a centre guy.

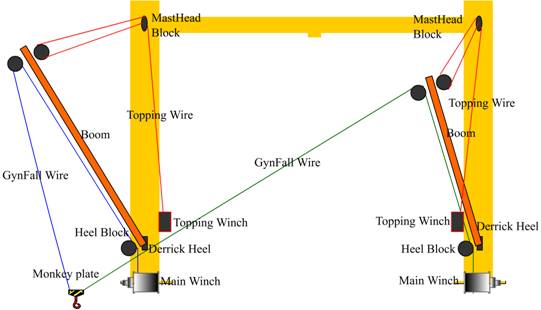

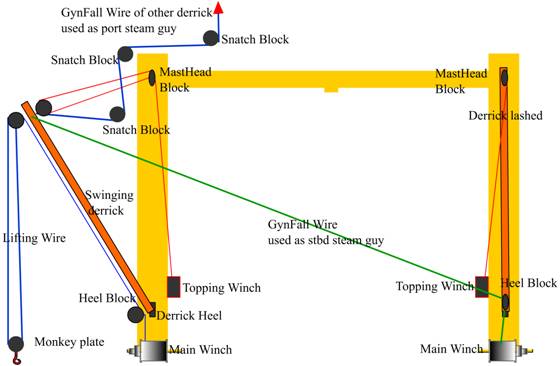

Rigging for

a Gun Tackle:

Using one of a set of derricks to load heavy loads,

this uses the gynfall wire of the other derrick as a steam (power) guy and also

uses the gynfall wire of another derrick as the other steam guy.

The derrick head block is connected to a floating

block and the gun tackle set up as shown below.

Working

with Derricks:

While topping/ lowering derricks the following are to

be ensured:

Both side guys are to be rigged and attended to.

As the derrick is being lowered or topped the guys are

to be heaved up or slackened.

The gynfall wire is to be slackened when topping up

the derrick

The person attending to the lock should be attentive

and at the slightest doubt about the speed or range of topping/ lowering he has

to release the lock. So that the derrick is prevented from having a free fall.

Lowering of the derrick should be within limits as set

out in the derrick rigging plan

While parking the derrick, the control over the side

guys should be especially good since with a slight swing the boom is liable to

damage other structures.

The derricks should not be lowered or topped if the

ship is rolling as this would make controlling the derrick very difficult.

The end rope of the controlling side guys should be

held after a full turn on the rams horn and there should be adequate clear

slack. In case of an emergency the next turns should be put on quickly

If a ram’s horn is not available then other suitable

points may be used, however railing are not to be used.

Derricks are secured either on a horizontal crutch

(light derricks) or vertically with clamping to the mast.

Prior to lowering the derrick the following are to be

inspected and if any are found wanting they are to be made good:

The crutch post and the bracket at the base are to be

inspected

The grommet attached to the eye pad (for the gynfall

wire) is to be inspected

The crutch wood sheathing is to be checked if damaged

then a canvas packing may be made in lieu

After the derrick is parked, the crutch clamp is to be

fitted and the locking arrangement fixed. There should be no play.

The side guys are to be tightened and fixed on either

side, the extra rope of the guys being neatly coiled onto pallets or slung on

railings and tied as a whole – the rope should be covered by a canvas cover

The gynfall wire hook is to be hooked to the grommet

and the wire tightened (just).

The topping wire should not have any weight, but

neither should it be slack

The heel of the derrick should be covered with canvas

and so should be the gynfall and the heel block

The preventer wire should be coiled and placed on a

pallet

Types of

Slings in common use:

Beside those mentioned there are various other slings

in use.

Plate sling: Normally the hinges clamp hangs loose,

but once fitted on to the plate and the wire pulled up, the clamps hold the

plate very firmly.

Open rope sling: This is used for various types of

delicate cargo. Not good for heavy weights.

Canvas sling: Used for lifting small bags of rice and other cereals, the canvas is useful for collecting any spillage that may be caused.

Snotter: This is used for various cargos. It is the

most versatile form of sling. Has been used even for container loading, by

attaching hook/ shackles to one end and using for such snotters.

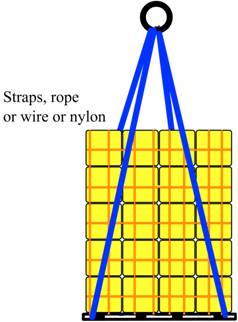

Pallet:

This is unitized cargo on a wooden pallet (the bottom

double tier of wood). Such cargo may be handles using wore slings but the more

safe and common is to use nylon straps or rope slings.

If the cargo is loaded on to the ship and the pallet

retains the nylon strap then it is termed as pre-slung cargo. The strap is

returned to the ship after discharging the cargo.

Hook

Handling:

Bales are soft cargo and they liable to be damaged by

hooks, which penetrate the surface and go deep inside.

Bales especially of hessian, bagged cargo and other

such cargo are rendered useless if the hooks punch holes into them.

Such cargo have a label saying use no hooks.

However many port workers use the same hooks to handle

these cargo

The preferred hooks for such cargoes are shown below.

These contain about 3 rows of small raised metal

pieces that good at gripping but do not damage the cargo.

Some bagged cargo come with ‘ears’ protruding from the

four corners of the bags, these ‘ears’ are material of the bag and facilitate

the handling of the cargo.

Unitized cargo and Pre-slung cargo

Unitized cargo are cargo such as tea or bagged sugar/

asbestos which are placed on top of a wooden pallet and are strapped together

into a unit.

The advantages of this is that the pallet (now

referred to the whole) is easily moved and stored by forklifts.

Much manual labour is not required. These types of

pallets may be stacked more than one high, though genially 2 high.

Ease of lashing and faster loading is the essential

advantages. However a lot of broken stowage occurs if the hold dimensions are

not square. Thus these type of cargo were unsuitable in old ships which had a

tunnel in the after holds and the bilges were rounded.

Since these cargo came with their own wooden pallets

the dunnaging cost was also saved.

After the development of unitized cargo, to speed up

further the handling process the cargo pallets were pre-slung with nylon

straps.

Thus a trailer arriving on the jetty had the pallets

neatly arranged and with their own slings. All it took from the shore labour

was for a person to hook on the slings. Once on board the slings were not

returned but the pallets was stowed with the sling. At the discharging port the

forklift brought the pallet top the hatch square and aging the pallet was lifted

out with the same sling. On completion of discharge if no cargo was being

loaded on the ship the slings were brought back on the ship. The slings were

the property of the ship and a strict tally was maintained. The slings were

made of nylon straps in various colours and were certified as to the SWL.

With the advent and popularization of containers

pre-slung cargo system died out. Unitized cargo is still existent and

containers are loaded with unitized cargo.

Cranes versus Derricks

Using various cargo gear for handling of cargo.

Until the early ‘80’s the primary gear was the

derrick. A ship would have a set 0of derricks for each hatch, sometimes if the

hatch was big the two sets of derricks. One for the fore part and the other for

the after part. The advantages of the derricks is that the boom never moved

after it was rigged into position. The only moving parts are the sheaves of the

blocks and the wires. As such it was and still is the fastest means of

discharging cargo.

The

advantages of discharging with derricks are:

Very few moving parts

Time to discharge the least

Not much skill required to operate the derricks

Breakdown rate low

Easy to maintain and to repair on board

Spares are easily obtained from even small workshops

Spares are cheap

The

disadvantages are:

Cannot discharge large and heavy packages

To be effective the derrick plumbing position has to

be properly judged.

Has to be re-rigged every time the discharge area or

loading square changes

Requires forklifts to feed the loading area

Cranes are used to handle heavy and large packages

including grabs on bulk carriers.

The advantages of the cranes are:

Can discharge from 360˚ angle

Can handle cargo from anywhere in the hatch square

Depending on the SWL of the crane can handle very

heavy packages

Sophisticated and has various safety cut outs to

prevent damage and accident.

The disadvantages are:

Is slow

Requires skilled person to operate

With unskilled labour requires frequent resetting of

the safety cut outs.

Maintenance difficult and time consuming

The good service provided by a crane is dependent on

the maintenance

Repairs even more difficult and time consuming

Spares are to be ordered in advance from the

manufacturer

Wires are of special construction and are very

expensive.

Rigging

other derricks:

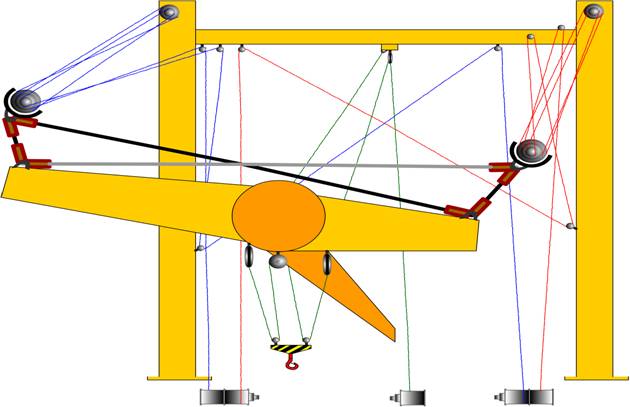

Velle Derrick Rigging

The above is a Velle derrick. This type of derrick is

a swinging derrick and is capable of lifting heavy weight and may be found on

container-oriented vessels (GC as well as container cargo).

The rig is one of the most complicated. On a ship the

crew has to be very well experienced to rig up this derrick. The length of the

wire is also of special length and may be of 250 – 280 metres.

There are 3 winches in operation; the 2 extreme

winches have separate barrels, which turn in the opposite direction. The

extreme winches share 2 wires, 1 wire starts at 1 winch and ends on the other.

The same is for the other wire.

The gynfall wire is on a single centre winch. The

controls are usually joystick control – 1 for the swinging and the other for

the lifting. Thus the extreme winches control the swinging as well as the

topping/ lowering action and are controlled by a single control joystick.

This is a rare rigging plan and the author has taken

great pains to personally draw it out while serving on a ship rigged with 22T

Velle derricks.

Use of

Forklifts:

The precautions prior lowering and using forklifts

inside the holds:

The forklift should not have any oil leakages

The height of the hold should be considered while

lowering a tall forklift

The weight of the forklift together with the cargo

should not exceed the load density of the hold

The forklift should not be emitting profuse quantities

of smoke

Adequate fire fighting arrangements should be inside

the hold for any fire of the forklift

Jute and other flammable cargo should be kept away

from any ingress of oil from any leaking forklift

The driver should not drive the forklift rashly

Adequate lighting should be ensured

Saw dust and sand should be kept stand by for any

unforeseen oil leaks.